8308756

Installation

Supplied Components

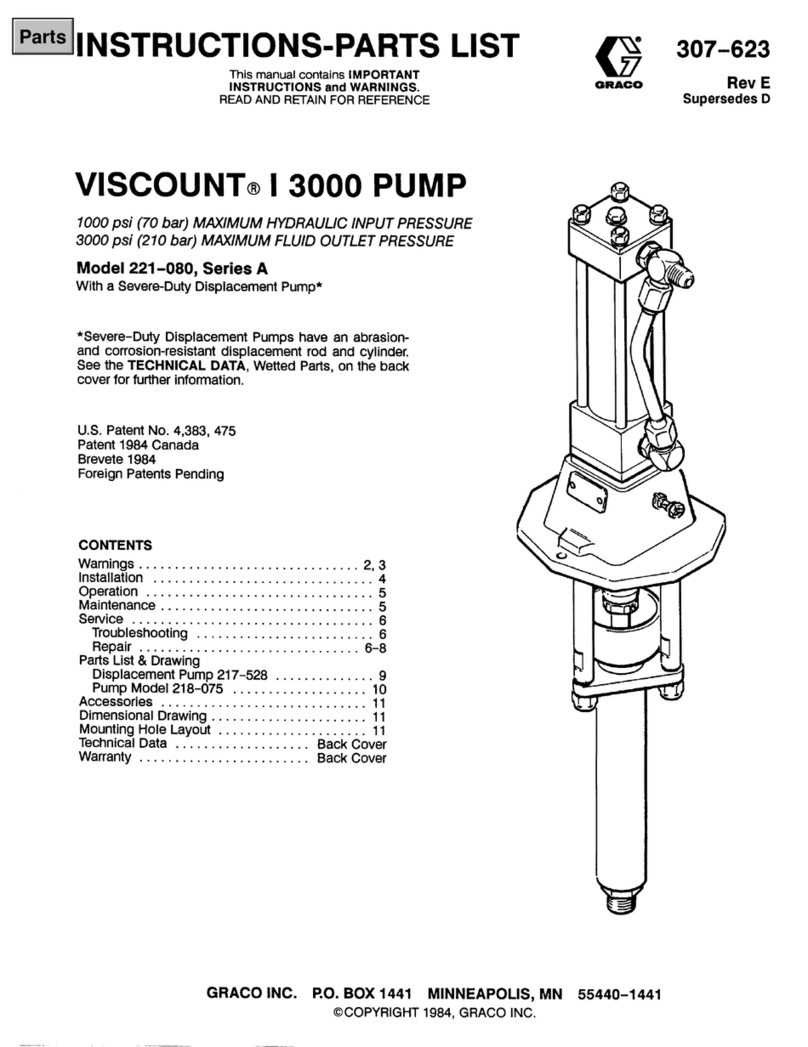

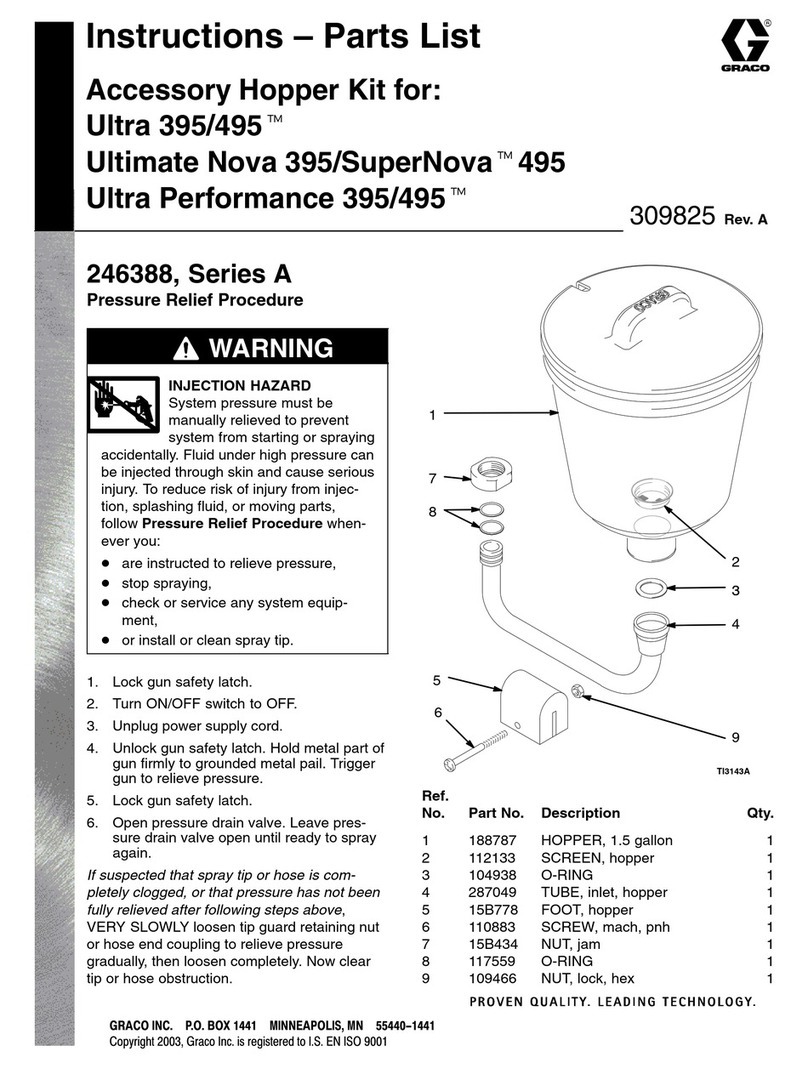

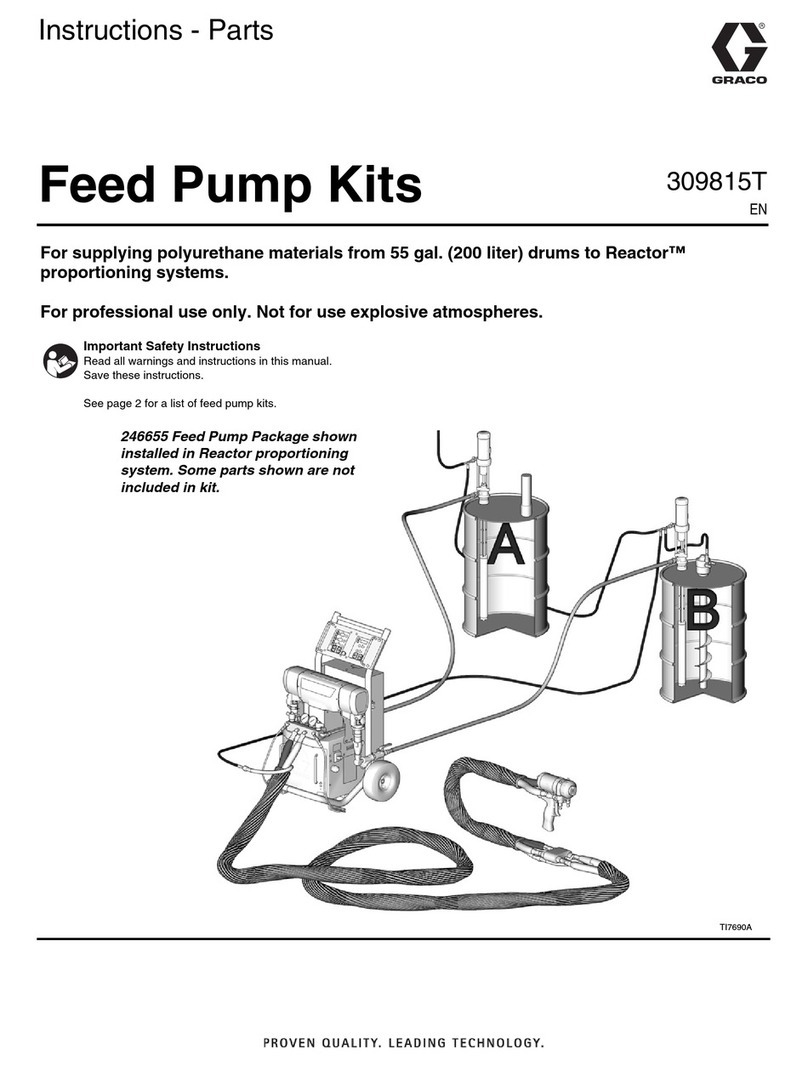

Refer to Fig. 1.

WARNING

A red-handled bleed-type master air valve (E) and

a fluid drain valve (F) are supplied. These compo-

nents help reduce the risk of serious injury, includ-

ing fluid injection and splashing of fluid in the eyes

or on the skin, and injury from moving parts if you

are adjusting or repairing the pump.

The bleed-type master air valve relieves air trapped

between this valve and the pump after the valve is

closed. Trapped air can cause the pump to cycle

unexpectedly. Locate the valve close to the pump.

The fluid drain valve assists in relieving fluid pres-

sure in the displacement pump, hose, and gun.

Triggering the gun to relieve pressure may not be

sufficient.

DThe red-handled bleed-type master air valve (E)

is required in your system to relieve air trapped

between it and the air motor when the valve is

closed (see the WARNING above). Do not block

access to the valve.

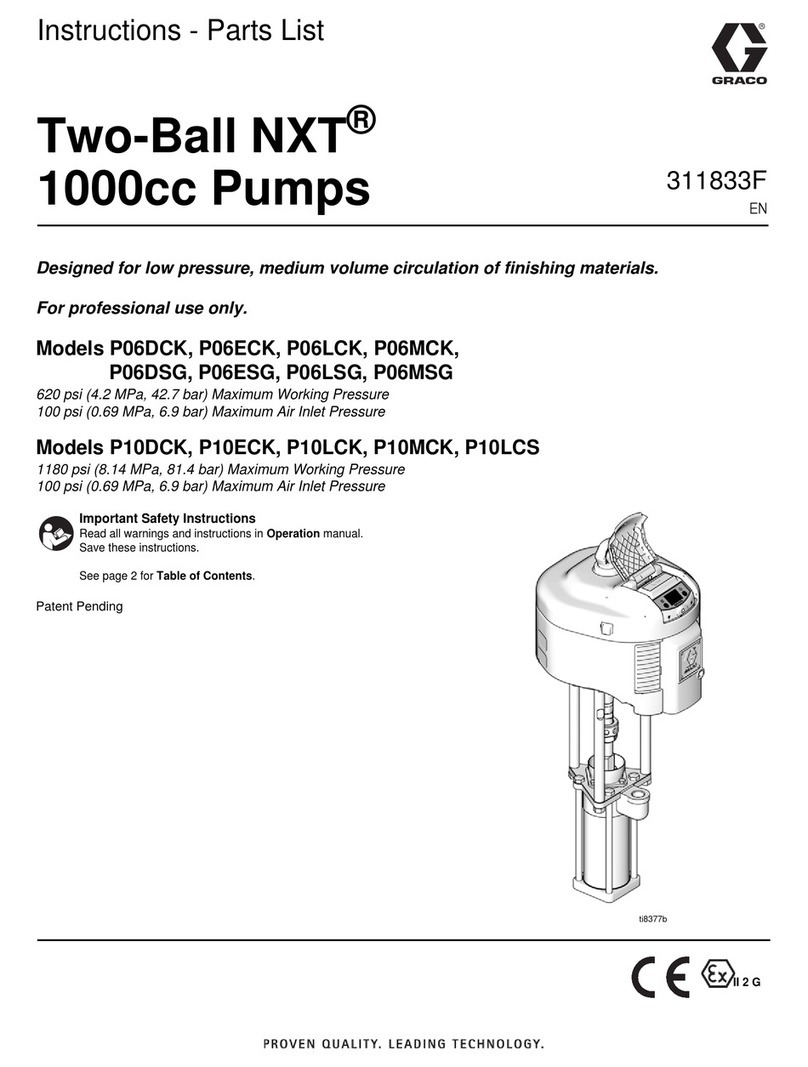

DThe pump air regulator (G) controls pump speed

and outlet pressure by adjusting the air pressure to

the pump.

DThe air relief valve (H) opens automatically to

prevent overpressurization of the pump.

DThe air inlet swivel (K) connects incoming air to

the pump.

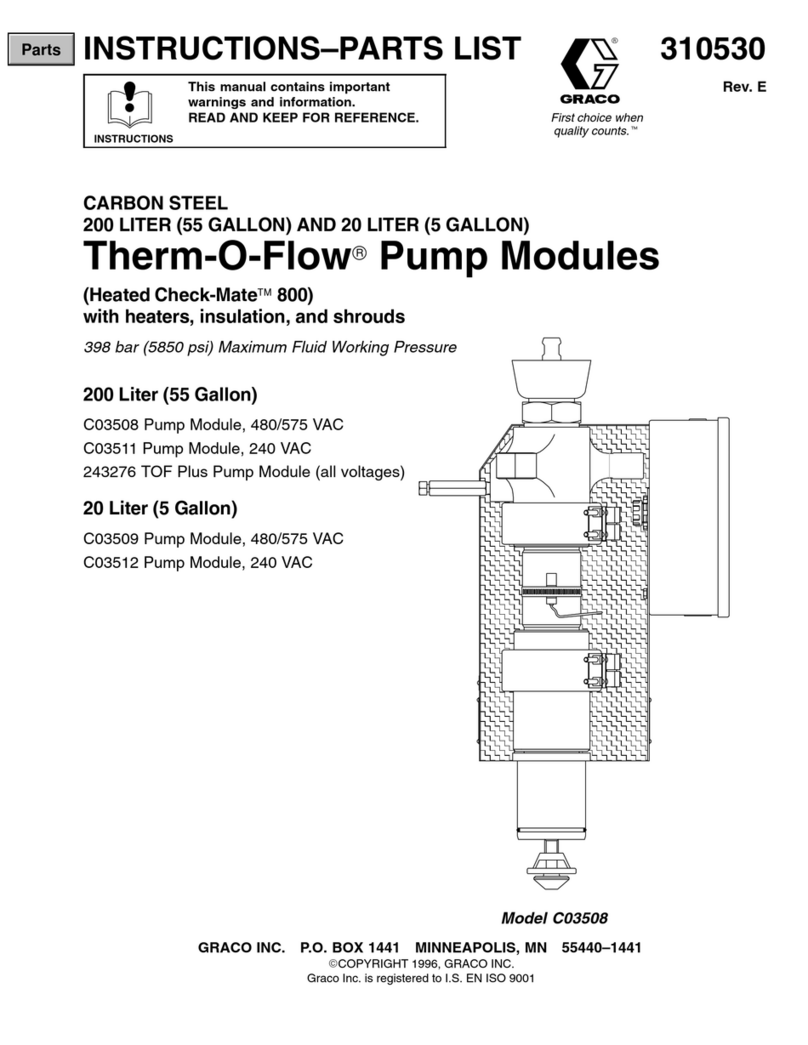

DThe suction hose (30) and tube (33) allow the

pump to draw fluid from a 55 gallon (200 liter) drum

(L). Carbon steel models include a bung adapter

(34) which screws into the drum’s bung hole.

DThe fluid filter (15) includes a 60 mesh (250

micron) stainless steel element to filter particles

from the fluid as it leaves the pump. It also includes

the fluid drain valve (F), which is required in your

system to relieve fluid pressure in the hose and gun

(see the WARNING above).

DThe airless spray gun (106) dispenses the fluid.

The gun houses the spray tip (107), which is

available in a wide range of sizes for different spray

patterns and rates of flow.

DThe fluid hose (101) and whip hose (103) supply

fluid to the gun.

DThe gun swivel (104) allows greater gun maneu-

verability. On Monark models using a fine finish

spray tip, the swivel includes an in-line filter.

Installing the Pump

NOTE: Refer to Fig. 1 and to the Dimension drawing

on page 22 and the Mounting Hole Layout on page 23.

1. Ensure that the wall is strong enough to support

the weight of the pump and accessories, fluid,

hoses, and stress caused during pump operation.

2. Position the bracket mounting plate (39) on the

wall so the edge with the hook is facing up. Refer

to page 23. Mount the plate so the top edge is 4 to

5 ft (1.2 to 1.5 m) above the floor. Check that the

plate is level. Mark two holes on the wall, using the

plate as a template. Drill two holes and attach the

plate with 1/2 in. bolts and washers.

3. Using two people, lift the pump assembly into

position and hang the pump bracket (1) on the

bracket mounting plate (39). Have one person hold

the assembly in place while the other checks that

the pump bracket (1) is level. Mark four holes on

the wall, using the pump bracket as a template. Lift

the bracket off the mounting plate (39).

4. Drill four holes in the wall.

WARNING

The pump bracket (1) must be bolted to the wall

with four bolts. Do not simply hang the pump

bracket on the bracket mounting plate (39).

5. Lift the pump assembly back into position, hang it

on the bracket mounting plate (39), and bolt the

pump bracket (1) to the wall. Use 1/2 in. bolts and

washers to mount the pump module to the wall.

Use bolts that are long enough to keep the pump

bracket (1) from vibrating during operation.