1-3

Spindl-Gard SG-1 and SG-2 Systems L42110

1.3.2.2 Controller. Several means of control are available for the

SG-1. Operation can be controlled by signals from user’s

machine control or by one of several controllers available

from Graco as follows:

WMP Maxi-Monitor• ®: This microprocessor-based

controller can be used to schedule and initiate lube

cycles on a machine cycle or time basis as well as

to relay fault conditions.

Solid-State Timer: This solid-state timer can be•

used to initiate lube cycles on a time basis. A

built-in memory retains the cycle time for 1-1/2

hours during power failure or machine shutdown to

resume from the point where it was suspended.

Flexi-Monitor: Utilizing the latest solid-state•

programmable control technology, the Flexi-Monitor

controls complex multiple-zone lubrication systems.

Not only does the Flexi-Monitor control lubrication

cycles, but it can monitor and report every aspect

of the lubrication system; including temperature,

vibration, fluid flow, pressure, and system operating

status.

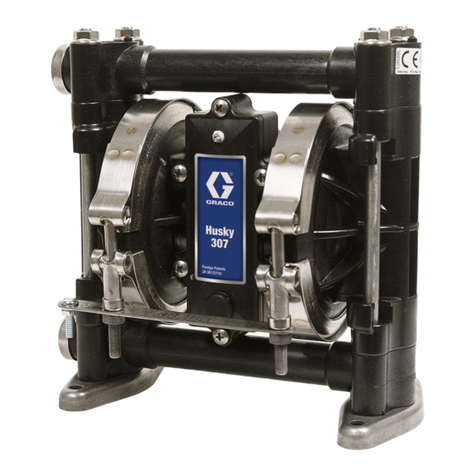

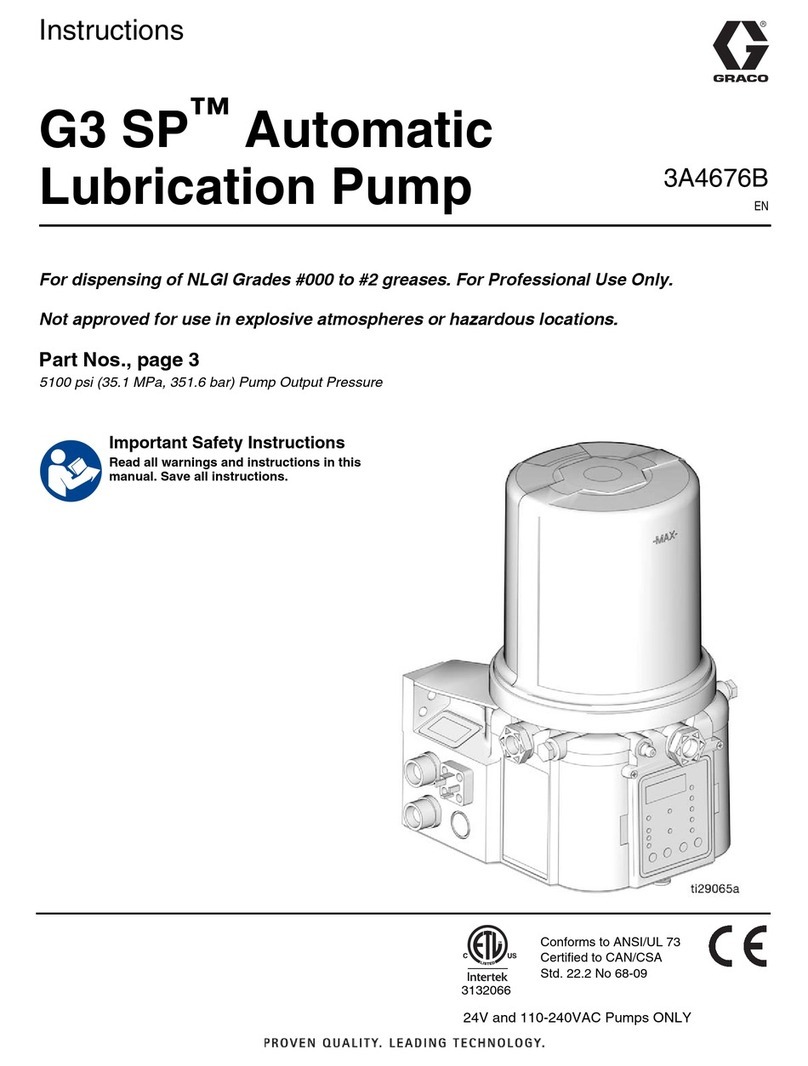

1.3.2.3 Pump Package. Several types of pump packages

are available to supply oil to the Spindl-Gard system.

Most applications use a Modu-Flo series pump

package equipped with a reservoir sized to the system

requirements. This series of pumps may either be

pneumatic- or hydraulic-powered and is available

in different lube output capabilities to fit the specific

requirements of each system.

1.3.2.4 Filter. A 10-micron filter placed in the outlet line of the

pump provides filtration of oil entering the system. A final

ten-micron oil filter at the divider valve inlet provides the

final filtration before oil enters the divider valve.

1.3.2.5 Divider Valve. This valve meters the precise amount of

oil required for each Spindl-Gard nozzle or terminating

lube point. The divider valve consists of stackable

sections, each of which can provide oil to one or two lube

points. The sections can be arranged to provide metered

oil to up to sixteen lube points. A valve section can be

supplied with a cycle indicator pin to provide visual

indication that the divider valve is cycling. The indicator

pin can also be used to actuate a cycle switch which

then provides a signal to the system controller.

1.3.2.6 Cycle Switch. The cycle switch is a limit switch which

is actuated by the movement of the cycle indicator pin.

If a blockage occurs in a lube line, the divider valve will

not cycle and the cycle switch will not be actuated. If

the switch is not actuated within a set time period, the

controller provides a warning signal.

1.3.2.7 Proximity Switch. The proximity switch is a proximity-

type sensor which is attached to the valve section of the

divider valve and senses the movement of the divider

valve piston during cycling. The proximity switch provides

a signal that is used to monitor the system in the same

manner as the cycle switch.

1.3.2.8 Spindl-Gard Spray Nozzle. The basic nozzle can be

installed in heads with walls up to 1-3/4 inches (44.4

mm) thick. It has separate 1/8 inch NPT inlet ports for air

and oil. Nozzle design and system air pressure (15 psi

(1 bar) at nozzle inlet) combine to provide a 60 degree

conical spray pattern.

1.3.2.9 Soft-Seat Check Valve. This valve, installed at the

bearing point, prevents oil drainage of the oil lines and

prevents air from entering the oil lines. An optional use

is installing the check valve at the lube inlet of the spray

nozzle.

1.3.2.10 2-psi Relief Valve. Installed at the lowest point of

the machining head gear cavity, this valve serves the

following functions:

It maintains a positive internal head pressure to•

prevent coolant and other contaminants from

entering the head.

By relieving at 2 psi, it prevents build-up of•

excessive pressure which could interfere with

proper oil dispersion.

It keeps the gear cavity dry by providing a simple•

means to drain off oil that would otherwise collect.

1.3.2.11 Pressure Switch. An optional 1-psi pressure switch

mounted to the machine head can be used to detect

changes in air pressure within the machining head cavity

due to broken air lines, clogged spray nozzles or worn

seals.

1.3.3 SG-1 Operation

NOTE: Refer to Figure 1-1 for item numbers referenced in the

descriptive paragraphs below.

1.3.3.1 The pump (1), and controller (3) are mounted on an

easily accessible part of the machine. The controller

energizes the pump at predetermined intervals to supply

lubricant to the system. The divider valve (7) with cycle

switch or proximity switch (4) supplies lubricant to either

spray nozzles or terminating lube points. The cycling of

the divider valve is monitored by the controller through

an electrical signal generated by either the cycle switch

or proximity switch. A pump failure, power failure, loss of

lubricant, plugged or crushed lube line, or broken supply

line would prevent the cycle switch or proximity switch

from producing the required signal to the controller,

which would register a fault condition.

1.3.3.2 The spray nozzle (9), supplied with constant clean dry

air (approximately 40 ºF (4.4 ºC) dewpoint, 5-micron

absolute filtration, at 15 psi (1 bar)), pressurizes the

machining head and supplies intermittent lube in the

form of a spray to the gears and bearings in the machine

head cavity. Air consumption is 0.6 scfm (17 sclm) per

nozzle. A relief valve (10) inserted at the lowest point

of each machining spindle cavity maintains positive air

pressure at 2 psi (0.14 bar). It also provides a simple

means to drain off any collected oil in the machine head