6 308–017

Installation

General Information

NOTE:

Reference numbers and letters in parentheses

in the text refer to the callouts in the figures and the

parts drawings.

NOTE:

Always use Genuine Graco Parts and

Accessories, available from your Graco distributor

.

Refer to the Product Data Sheet, Form No. 305–546. If

you supply your own accessories, be sure they are

adequately sized and pressure-rated to meet the

system’

s requirements.

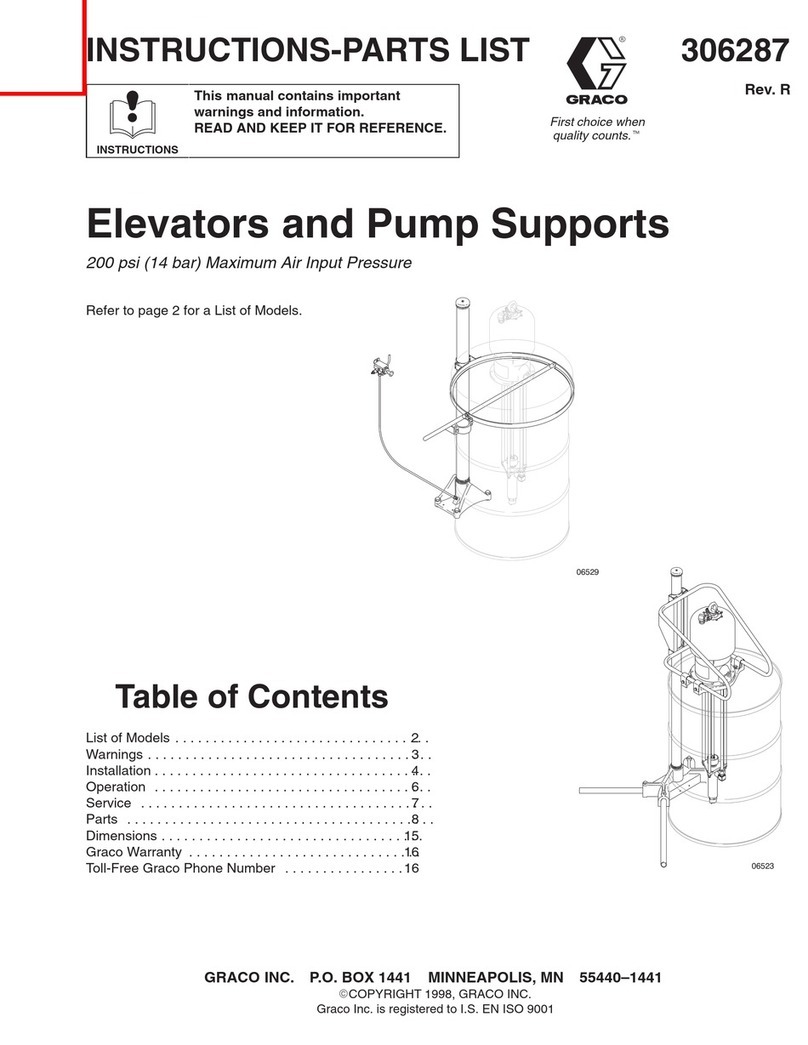

Fig. 1 is only a guide for selecting and installing sys

-

tem components and accessories. Contact your Graco

distributor for assistance in designing a system to suit

your particular needs.

System Accessories

WARNING

A

red-handled main air bleed valve (V), pump air

bleed valve (G), and fluid drain valve (L) are re

-

quired. These accessories help reduce the risk of

serious injury

, including fluid injection and splashing

of fluid in the eyes or on the skin, and injury from

moving parts if you are adjusting or repairing the

pump.

The red-handled main air bleed valve (V) shuts of

f

and relieves the air to the pump and ram. Order

Part No. 1

13–269 for Monark and President

Pumps, or 113–218 for Senator and Bulldog

Pumps. The ram will hold pressure if the ram

director valve (U) is in the horizontal (neutral)

position. T

o relieve air pressure in the ram, close

the red-handled bleed valve (V) and move the

director valve (U) to DOWN. The ram will slowly

drop.

The pump air bleed valve (G) relieves air trapped

between it and the pump after the air is shut of

f.

T

rapped air can cause the pump to cycle unexpect

-

edly

. Locate the valve close to the pump.

The fluid drain valve (L) assists in relieving fluid

pressure in the displacement pump, hose, and gun.

T

riggering the gun to relieve pressure may not be

suf

ficient. Order Part No. 210–658 (3/8 npt).

Air Line

Install the following accessories as shown in Fig. 1,

using adapters as necessary:

A red-handled main air bleed valve (V)

is re

-

quired in your system to shut of

f the air supply to

the pump and ram (see the

WARNING

at left).

When closed, the valve will bleed of

f all air in the

ram and pump, and the ram will slowly drop. Be

sure the valve is easily accessible from the pump,

and is located

upstream

from the air manifold (D).

The pump air bleed valve (G)

is required in your

system to relieve air trapped between it and the air

motor when the valve is closed (see the

WARNING

at left). Be sure the valve is easily accessible from

the pump, and is located

downstream from the air

regulator (H).

The

pump air regulator (H)

controls pump speed

and outlet pressure by adjusting the air pressure to

the pump. Locate the regulator close to the pump,

but

upstream

from the pump air bleed valve (G).

An

air line lubricator (F)

provides automatic air

motor lubrication.

A

pump runaway valve (E

) senses when the

pump is running too fast and automatically shuts of

f

the air to the motor

. A pump which runs too fast can

be seriously damaged.

An air manifold (D)

has a swivel air inlet. It has

ports for connecting lines to air accessories, such

as the

ram air regulator (T),

which controls the air

pressure to the ram.

The air pressure relief valve (Q)

limits the air

pressure to the ram to 10 bar (150 psi).

The ram director valve (U)

controls the raising

and lowering of the ram.

An

air line filter (J)

removes harmful dirt and mois

-

ture from the compressed air supply

. Also, install a

drain valve (W)

at the bottom of each air line drop,

to drain off moisture.

A bleed-type air valve (K)

isolates the air line ac

-

cessories for servicing. Locate upstream from all

other air line accessories.