8308-151

OPERATION/MAINTENANCE

Pressure Relief Procedure

T

o reduce the risk of serious bodily injury

, including

fluid

injection, splashing in the eyes or on the skin, or

injury from moving parts, always follow this proce-

dure

whenever you shut of

f the pump, when check

-

ing

or servicing any

part of the spray/dispensing sys

-

tem, when installing, cleaning or changing spray

tips/nozzles, and whenever you stop spraying/dis-

pensing.

1. Engage the spray gun/dispensing valve safety

latch.

2. Shut

off the air or hydraulic supply to the pump.

3. In air–powered systems, close the bleed–type

master air valve (required in your system). In

hydraulic–powered

systems, close the hydraulic

supply

line valve

first

, then the return line valve.

4.

Disengage the gun/valve safety latch.

5. Hold a metal part of the gun/valve firmly to the

side

of a grounded metal pail, and trigger the gun/

valve

to relieve pressure.

6.

Engage the gun/valve safety latch.

7. Open the drain valve (required in your system)

and/or the pump bleeder valve, having a con-

tainer

ready to catch the drainage.

8. Leave

the drain valve open until you are ready

to

spray/dispense

again.

If you suspect that the spray tip/nozzle or hose is

completely clogged, or that pressure has not been

fully

relieved after following the

steps above,

VER

Y

SLOWLY

loosen the tip guard retaining nut, nozzle,

or

hose end coupling and relieve pressure gradually

,

then

loosen completely

. Now clear the tip/nozzle or

hose.

WARNING

P

ACKING NUT/WET–CUP (ALL MODELS)

Fill

the packing nut/wet–cup (3) 1/3 full with Graco Throat

Seal

Liquid (TSL) or compatible solvent. See Fig. 2. Us

-

ing the supplied wrench (104), adjust the packing nut

weekly so it is just snug; do not overtighten. Follow the

Pressure

Relief

Procedure W

arning

above before ad

-

justing

the packing nut.

FLUSHING THE PUMP (ALL MODELS)

The

pump is tested with lightweight oil, which is left in to

protect the pump parts. If the fluid you are using may be

contaminated

by the oil, flush it out with a compatible sol

-

vent

before using the pump.

For your safety , read the warning section, FIRE

OR

EXPLOSION HAZARD

on page 3 before flush

-

ing,

and follow all the recommendations given

there.

WARNING

OPERATION

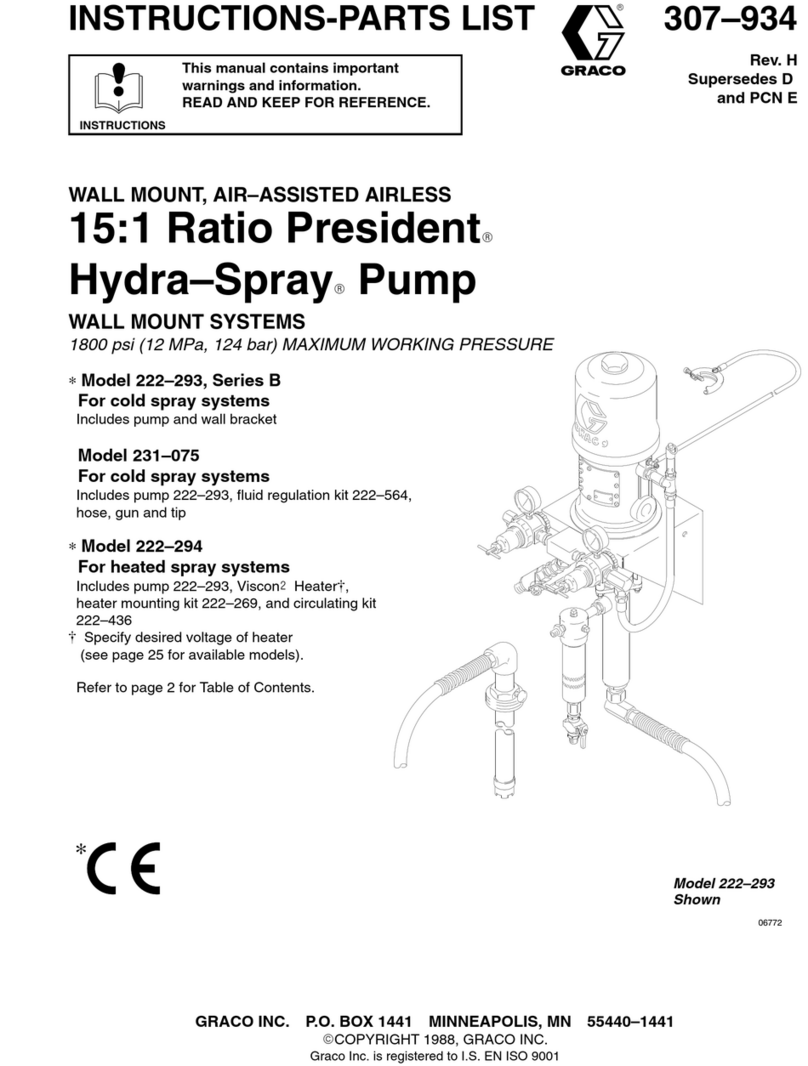

(AIR–POWERED MODELS)

Starting and Adjusting the Pump

Refer

to the

TYPICAL

INST

ALLATION

on page 4. Con

-

nect

the suction kit (T) to the pump’

s fluid inlet, and place

the

tube into the fluid supply

.

Be sure the air regulator (F) is closed. Then open the

pump’s

bleed–type master air valve (E). Hold a metal part

of

the spray gun/dispensing valve (S) firmly to the side

of

a grounded metal pail and hold the trigger open. Now

slowly

open the air regulator until the pump starts.

Cycle

the pump slowly until all the air is pushed out

and

the

pump and hoses are fully primed. Release the spray

gun/dispensing

valve trigger and engage the safety

latch.

The

pump should stall against pressure when the

trigger

is

released.

If

the pump fails to prime properly

, open the bleeder valve

(24)

slightly

. Use the bleed hole, on the underside of the

valve, as a priming valve until the fluid appears at the

hole.

See Fig 2. Close the bleeder valve.

NOTE: When changing fluid containers with the hose

and

gun already

primed, open the bleeder valve

(24),

to assist in priming the pump and venting air

before it enters the hose. Close the bleeder valve

when

all air has been eliminated.

To reduce the risk of fluid injection, DO NOT use

your hand or fingers to cover the bleed hole when

priming

the pump.

WARNING

With the pump and lines primed, and with adequate air

pressure and volume supplied, the pump will start and

stop

as the gun/valve is opened and closed. In a

circulat

-

ing

system, the pump will speed up or slow down on de

-

mand,

until the air supply is shut of

f.

Use the

air regulator to control the pump speed and the

fluid

pressure. Always use the lowest

air pressure neces

-

sary to get the desired results. Higher pressures cause

premature

tip/nozzle and pump wear

.

To

reduce the risk of overpressurizing your system,

which could result in component rupture and cause

serious bodily injury,

NEVER exceed the specified

MAXIMUM INCOMING AIR PRESSURE to the

pump

(see the T

echnical Data on pages 24–27).

WARNING

Never allow the pump to run dry of the fluid being

pumped. A dry pump will quickly accelerate to a high

speed,

possibly damaging itself. A pump runaway valve

(C),

which shuts of

f the air supply to the pump if the pump

accelerates

beyond the

pre–set speed, is available. See

the Typical Installation on page 4 and ACCESSORIES

on page 22. If your pump accelerates quickly, or is run-

ning

too fast, stop it immediately and check the fluid

sup

-

ply. If the supply container is empty and air has been

pumped into the lines, refill the container and prime the

pump and the lines with fluid, or flush and leave it filled

with

a compatible solvent. Be sure to eliminate all air from

the

fluid system.

Shutdown and Care of the Pump

For

overnight shutdown, follow the

Pressure Relief Pro

-

cedure

W

arning

at left. Stop the pump at the bottom of

the

stroke to prevent fluid from drying on the exposed

dis

-

placement

rod and damaging the throat packings.

Always flush the pump before the fluid dries on the dis-

placement

rod. Never leave water or water–based fluid in

the pump overnight. First, flush with water or a compat-

ible solvent, then with mineral spirits. Relieve the pres-

sure,

but leave the

mineral spirits in the pump to protect

the

parts from corrosion.