Operation

After wiring is complete, supply power to the GRX-PWM to check for proper operation.

•With the cover removed, an LED will provide visual feedback about the operation of the system.

•When power is first applied, the LED will turn on for 8 seconds to indicate start-up mode and then start to flash in one of two ways

to indicate the status of the system:

1. Standard Operation

•The LED will flash at a rate of twice per second to signify proper communication between the Control Unit and the Interface.

2. Incorrect Operation - No Active Input

•The LED will repeatedly turn on for 1 second, then off for 1 second, to indicate that there is not an active phase control input to

the GRX-PWM. Make sure that the phase control dimmer is ON and connected to the GRX-PWM at the terminal block marked

DH2. Check that the corresponding zone for the DH2terminal is ON and the light level is not set at the minimum output.

•When the LED indicates proper input of a phase control signal, then the output can be checked by looking at the load and

checking operation from the Control Unit.

•For non-dimming ballasts, select non-dim load type on the

GRAFIK Eye

Control Unit and do not connect ballasts to PWM’s + and -

terminals.

Make sure that the Control Unit is set for Fluorescent Load Type. (Refer to

GRAFIK Eye

3000 Series Installer's Guide.) If the

load type is not set correctly, proper dimming will not occur.

Solution

Verify that LED pulses twice per second. If not, check wiring from phase control unit to the

Interface.

Make sure that the

GRAFIK Eye

3000 Series Control Unit is ON.

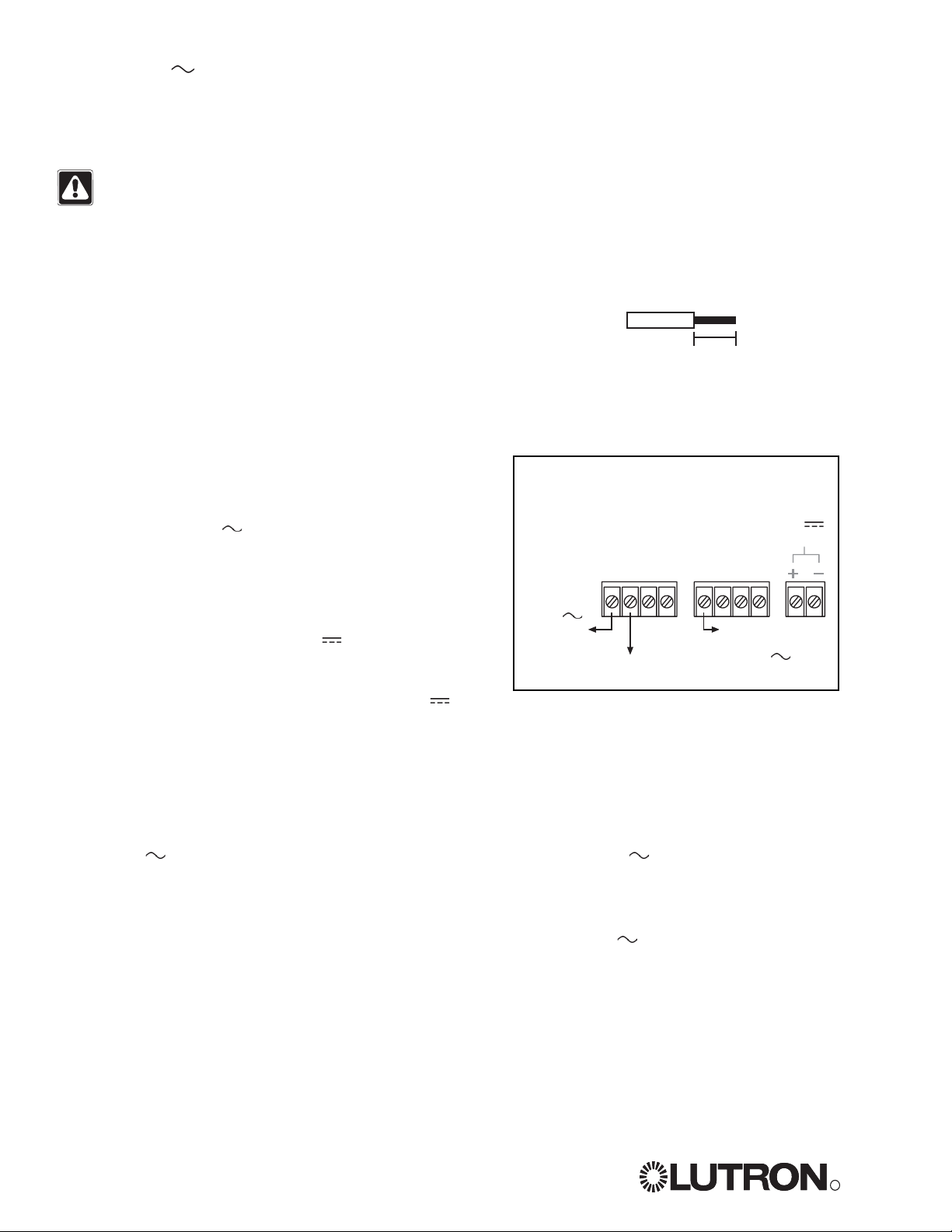

Check for proper polarity of PWM signals at terminal blocks. Does it match what is at every

ballast? A miswire at any ballast will cause all ballasts to go to the low end.

GRAFIK Eye

3000 Series Control Unit is not configured for fluorescent load type.

Check that the SH1connection goes to the ballasts.

Check that the DH2connection is actually wired to a phase control input.

Check that load is connected to SH terminal.

Check that the DH2connection is actually wired to a phase control input.

Check that power is applied to the Interface.

Symptom

PWM Ballast does not dim or control

unit to the Interface.

Light does not switch on

Light does not switch off

LED is not illuminated

Possible Cause

Miswire

Power is OFF

Miswire

Incorrect control setup

Miswire

Miswire

Miswire

Miswire

No power input

Troubleshooting

Lutron Electronics Co., Inc.

Made and printed in U.S.A. 2/06

P/N 031-267 Rev. A

LIMITED WARRANTY

Lutron will, at its option, repair or replace any unit that is

defective in materials or manufacture within one year after

purchase. For warranty service, return unit to place of purchase

or mail to Lutron at 7200 Suter Rd., Coopersburg, PA 18036-

1299, postage pre-paid.

This warranty is in lieu of all other express warranties, and the

implied warranty of merchantability is limited to one year from

purchase. This warranty does not cover the cost of installation,

removal or reinstallation, or damage resulting from misuse,

abuse, or improper or incorrect repair, or damage from improper

wiring or installation. This warranty does not cover incidental or

consequential damages. Lutron’s liability on any claim for

damages arising out of or in connection with the manufacture,

sale, installation, delivery, or use of the unit shall never exceed

the purchase price of the unit.

This warranty gives you specific legal rights, and you may also

have other rights which vary from state to state. Some states do

not allow limitations on how long an implied warranty lasts, so

the above limitation may not apply to you. Some states do not

allow the exclusion or limitation of incidental or consequential

damages, so the above limitation or exclusion may not apply to

you.

This product may be covered by one or more of the following

U.S. Patents: 4,797,599; 5,309,068; 5,633,540; and

corresponding foreign patents.

Nomex

is a registered trademark of E.I. Du Pont de Nemours and

Company.

Lutron, the sunburst logo, and GRAFIK Eye are registered

trademarks; Eco-10 is a trademark of Lutron Electronics Co., Inc.

© 2006 Lutron Electronics Co., Inc.

Internet: www.lutron.com

WORLD HEADQUARTERS

Lutron Electronics Co., Inc.

7200 Suter Road, Coopersburg, PA 18036

TEL +1-610-282-3800

FAX +1-610-282-1243

EUROPEAN HEADQUARTERS

Lutron EA Ltd.

6 Sovereign Close, Wapping, London, E1W

3JF United Kingdom

TEL +44-207-702-0657

FAX +44-207-480-6899

FREEPHONE (UK) 0800-282-107

Technical support +44-(0)20-7680-4481

WORLDWIDE OFFICES

Brazil

Lutron BZ do Brasil Ltda.

AV, Brasil, 239, Jardim America,

Sao Paulo-SP, CEP01431-000, Brasil

TEL +55 11 3885-5152

France

Lutron LTC, S.A.R.L.

90 rue de Villiers, 92300 Levallois-Perret

France

TEL +33-(0) 1-41-05-42-80

FAX +33-(0) 1-41-05-01-80

FREEPHONE 0800-90-12-18

Germany

Lutron Electronics GmbH, Landsberger

Allee 201, 13055 Berlin, Germany

TEL +49-309-710-4590

FAX +49-309-710-4591

FREEPHONE 00800-5887 6635

Italy

Lutron LDV, S.r.l.

FREEPHONE 800-979-208

Spain, Madrid

Lutron CC, S.R.L.

Calle Orense, 85, 28020 Madrid, Spain

TEL +34-91-567-84 79

FAX +34-91-567-84 78

FREEPHONE 0900-948-944

Spain, Barcelona

Lutron CC, S.R.L.

Gran Via del Carlos III, 84, planta 3a,

08028,

Barcelona, Spain

TEL +34-93-496-57 42

FAX +34-93-496-57 01

FREEPHONE 0900-948-944

China, Beijing

Lutron GL Ltd.

5th Floor, China Life Tower, No. 16 Chaowai

Street, Chaoyang District, Beijing 100020

China

TEL +86-10-5877-1817

FAX +86-10-5877-1816

China, Shanghai

Lutron GL Ltd.

Suite 07, 39th Floor, Plaza 66,

1266 Nan Jing West Road, Shanghai,

200040 China

TEL +86-21-6288-1473

FAX +86-21-6288-1751

China, Guangzhou

Lutron GL Ltd. Guangzhou Representative

Office

Plaza Business and Conference Centre

(Guangzhou)

Suite A09, 23/F Tower A, Center Plaza,

161 LinHeXiLu, Tianhe District, Guangzhou

510620 China

TEL +86-20-2885-8266

FAX +86-20-2885-8366

Hong Kong

Lutron GL Ltd.

Room 2808, 28/F, 248 Queen's Road East,

Wanchai, Hong Kong

TEL +852-2104-7733

FAX +852-2104-7633

Japan

Lutron Asuka Co. Ltd.

No. 16 Kowa Building, 4F, 1-9-20, Akasaka,

Minato-ku, Tokyo 107-0052 Japan

TEL +81-3-5575-8411

FAX +81-3-5575-8420

Singapore

Lutron GL Ltd.

6A Upper Cross Street, Singapore 058326

TEL +65-6220-4666

FAX +65-6220-4333

Asia Technical Hotlines

Northern China: 10-800-712-1536

Southern China: 10-800-120-1536

Hong Kong: 800-901-849

Singapore: 800-120-4491

Taiwan: 00-801-137-737

Thailand: 001-800-120-665853