Page: 4/22 Revision 1.01 Date: 2016-05-27

Checklist

Before starting the upgrade process, make sure that all conditions in the following part list are fulfilled:

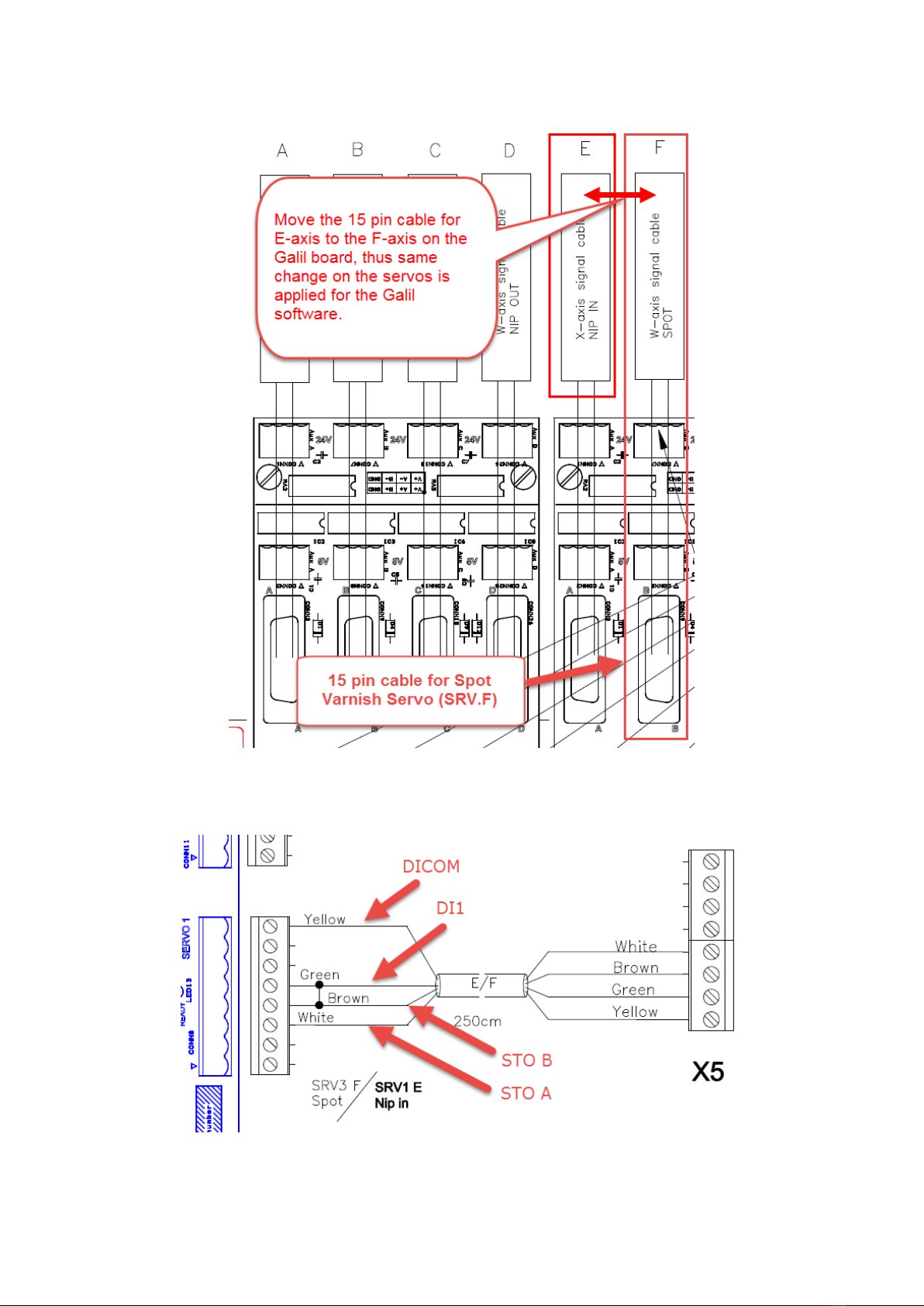

1. Extra servo driver, programmed for spot varnish.

2. Servo motor and wiring cables.

3. Correct program for the Galil software.

4. Spot home inductive sensor including bracket.

5. Side adjustment encoder.

6. Side adjustment for varnish roller.

7. Optional: Schneider programming cable –just in case.

1. GeneralInformation

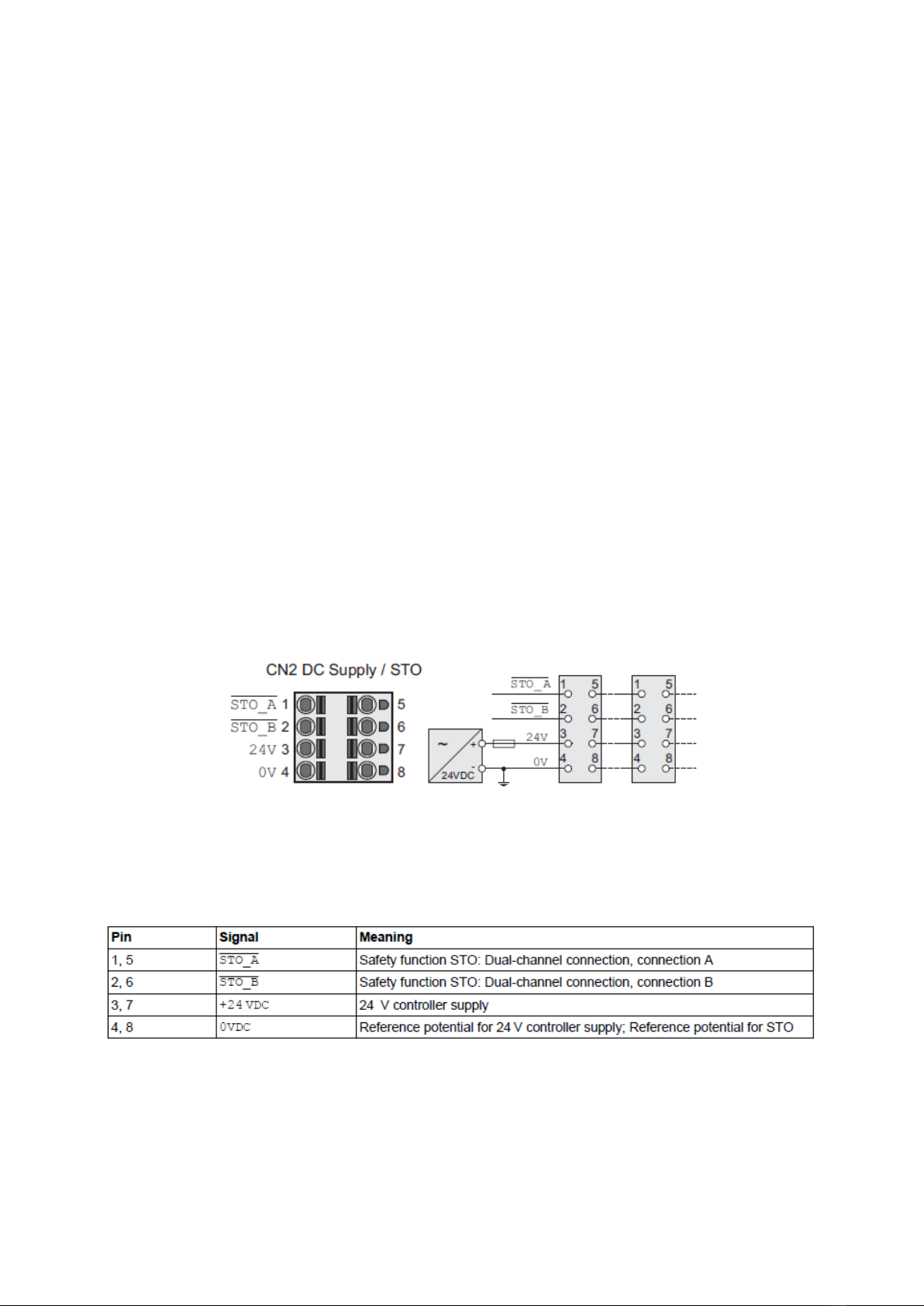

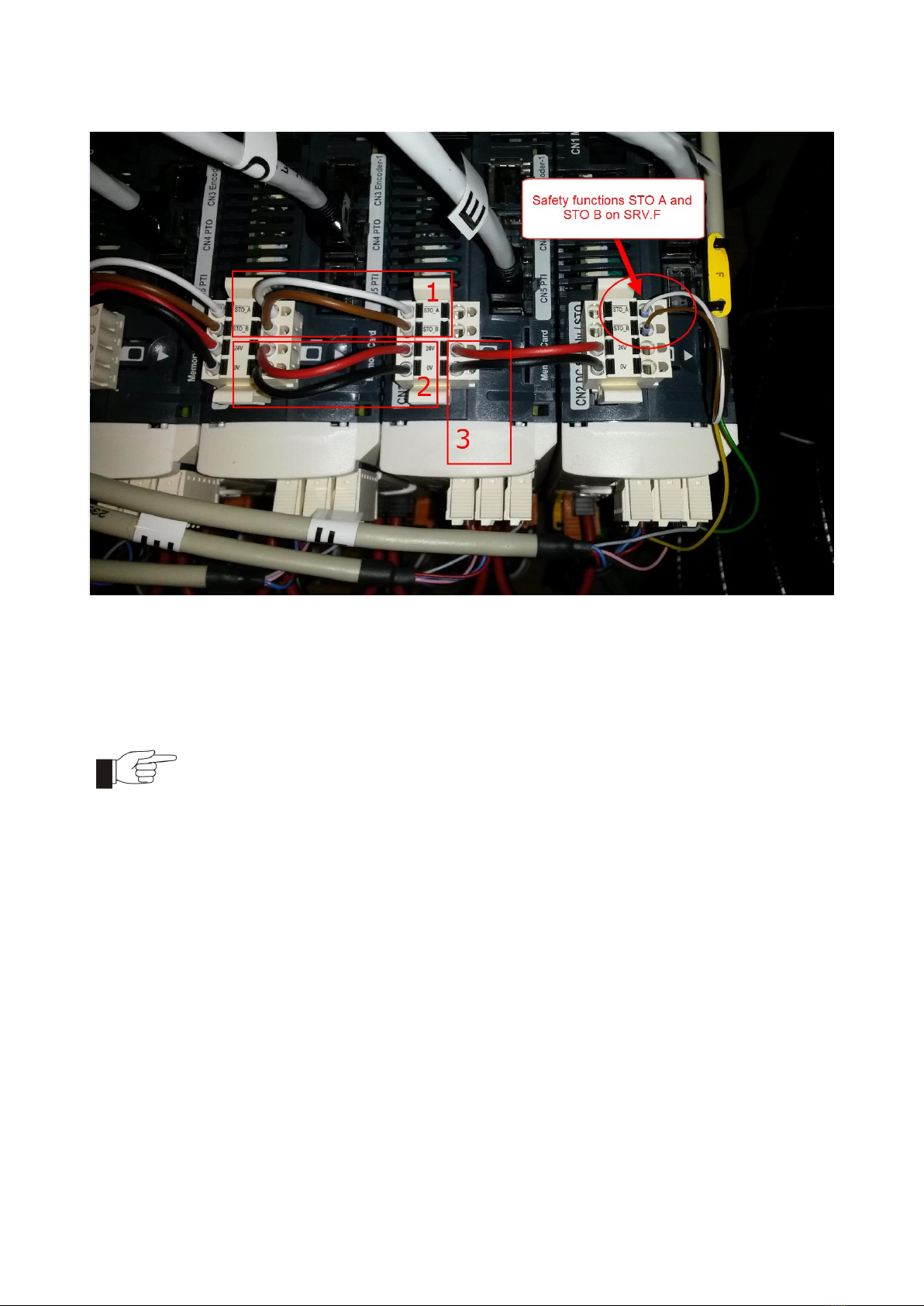

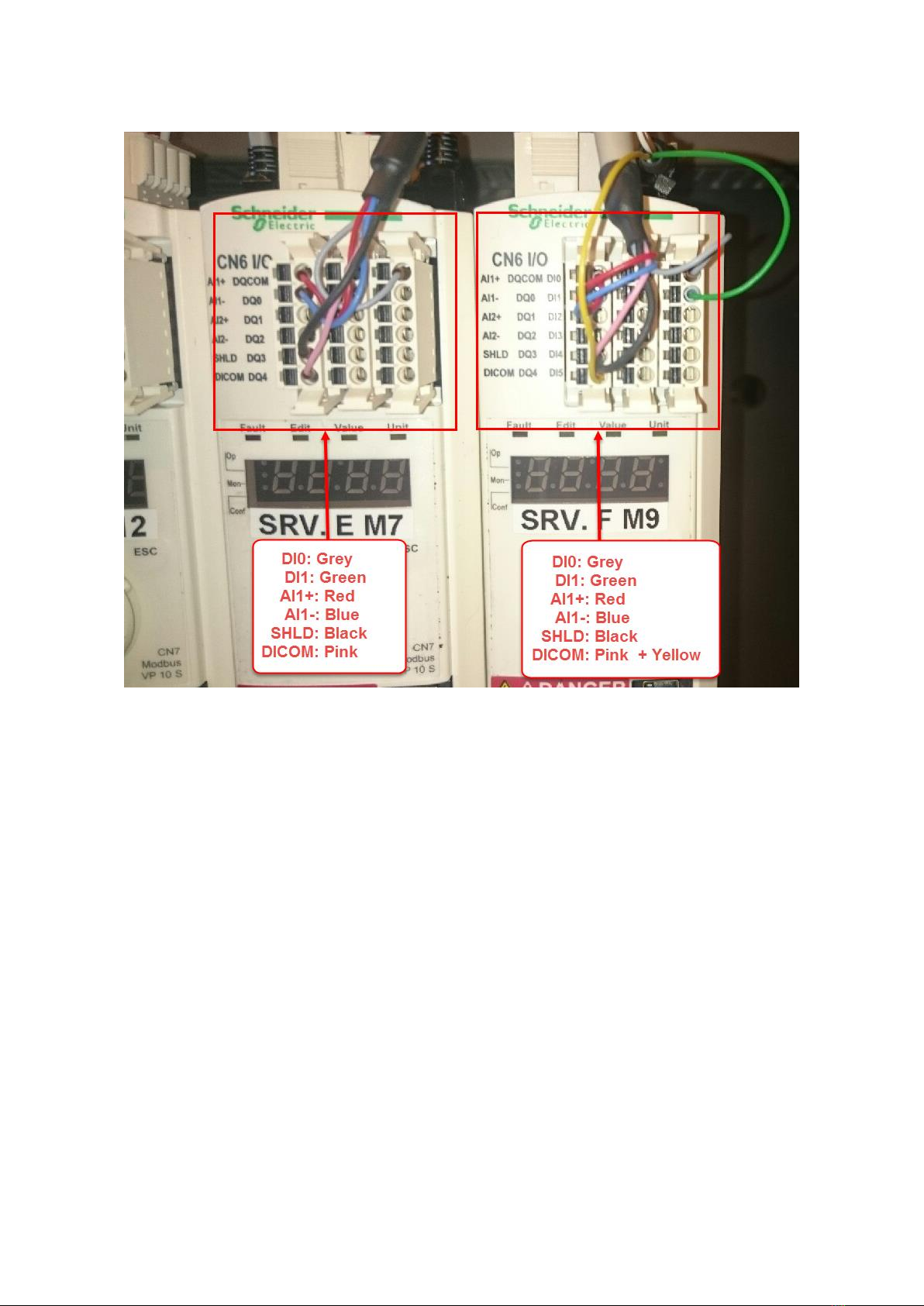

Awiringdiagram ofthemainconnectorsontheservos,thatwillbeusedinthismanualare showninFigure

1 and Figure 2. Also notice that the table here below refers onlyto the wiring diagram in Figure 1.

Figure 1: Wiring diagram controller supply (on top of servo drive).