EU Declaration of Conformity..................................................................................................................... 2

1. Safety instructions............................................................................................................................... 5

2. DC330mini/nano note......................................................................................................................... 6

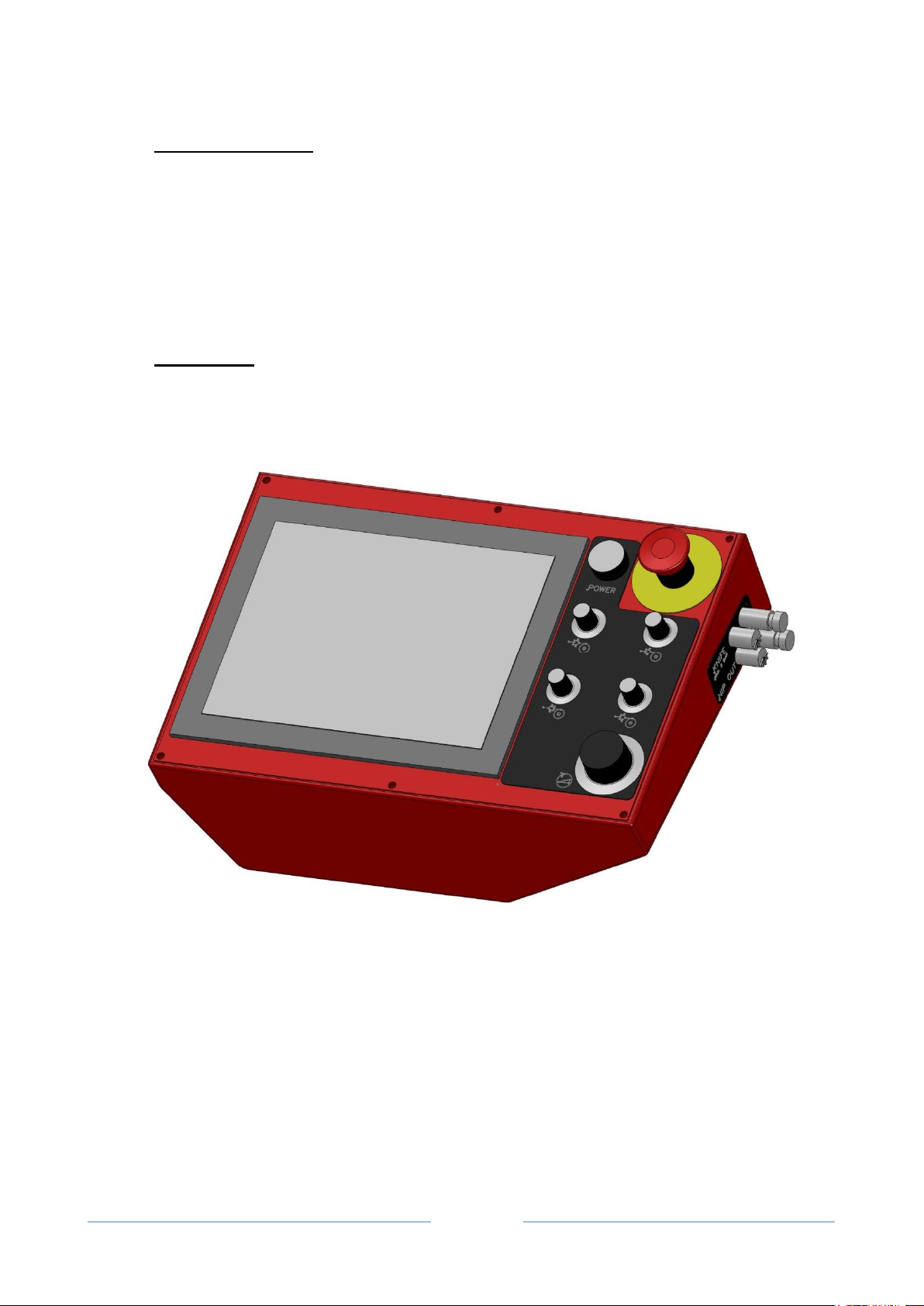

3. Control panel........................................................................................................................................ 6

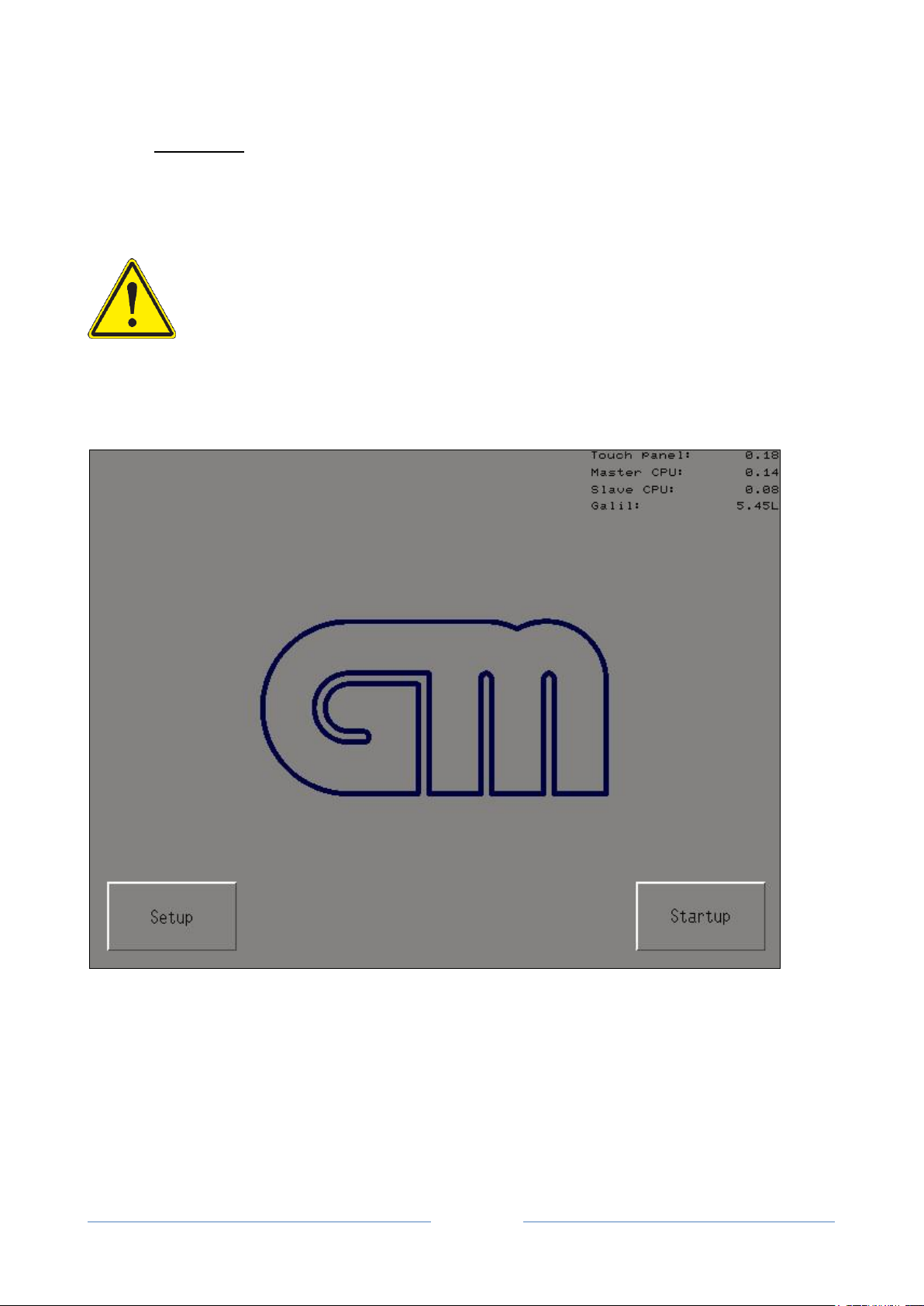

4. Touch panel.......................................................................................................................................... 7

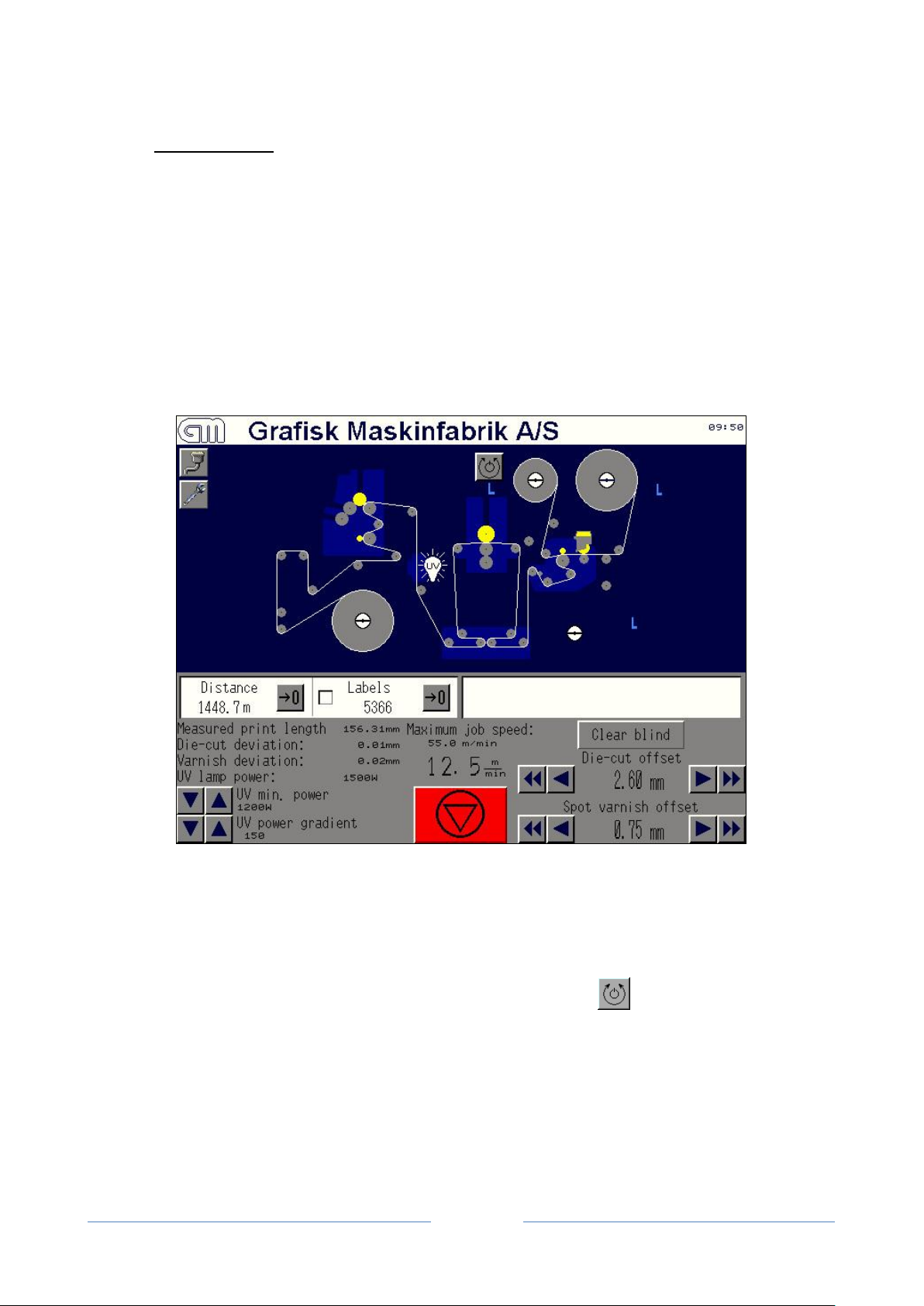

5. The main screen................................................................................................................................... 8

5.1. Web entry...........................................................................................................................................9

5.2. The varnish station.............................................................................................................................9

5.3. The spot varnish option .....................................................................................................................9

5.4. The laminating station (optional)......................................................................................................9

5.5. The UV lamp................................................................................................................................... 11

5.6. Safety instructions........................................................................................................................... 12

5.7. The die-cutting station.................................................................................................................... 13

5.8. Waste rewinder ............................................................................................................................... 14

5.9. V-knifes and Slitting knifes............................................................................................................ 14

5.10. Rewinding....................................................................................................................................... 15

6. Menu buttons.....................................................................................................................................16

6.1. Parameters....................................................................................................................................... 18

6.2. Die-cut parameters.......................................................................................................................... 20

6.3. Speed control................................................................................................................................... 23

6.4. Web tension and scale print adjustments....................................................................................... 24

7. Alarms and messages........................................................................................................................25

8. Language and units setup.................................................................................................................29

9. Special parameters............................................................................................................................30

10. Registration accuracy....................................................................................................................... 31

11. Markreader SUNX LX series..........................................................................................................32

12. Distortion and disprofactor.............................................................................................................33

13. Varnish station –prevent dripping.................................................................................................35

14. Dust problems with V-knifes & damages to anvil roller.............................................................36

15. Die cut station adjustment and alignment.....................................................................................36

16. Die cut bridge adjustment................................................................................................................ 37

17. General information for GM diecut station..................................................................................38

18. Varnish station................................................................................................................................... 41

18.1. Technical data ................................................................................................................................. 41

18.2. Anilox roller types .......................................................................................................................... 43

18.3. Mounting of the anilox roller ......................................................................................................... 44