Graham Architectural Products

Homeowner’s Manual

Acoustical Aluminum Windows

2

Congratulations . . . and thank you for your selection of Graham Architectural Products windows,

which have become an integral part of your new home or replacement window project. All our

products are manufactured to the highest possible standards. All Graham windows and patio doors

are engineered and randomly selected for testing by certified third party laboratories to assure that

our products perform as designed day in and day out. Like any highly-engineered product,

periodic maintenance is required to assure a lifetime of low maintenance performance.

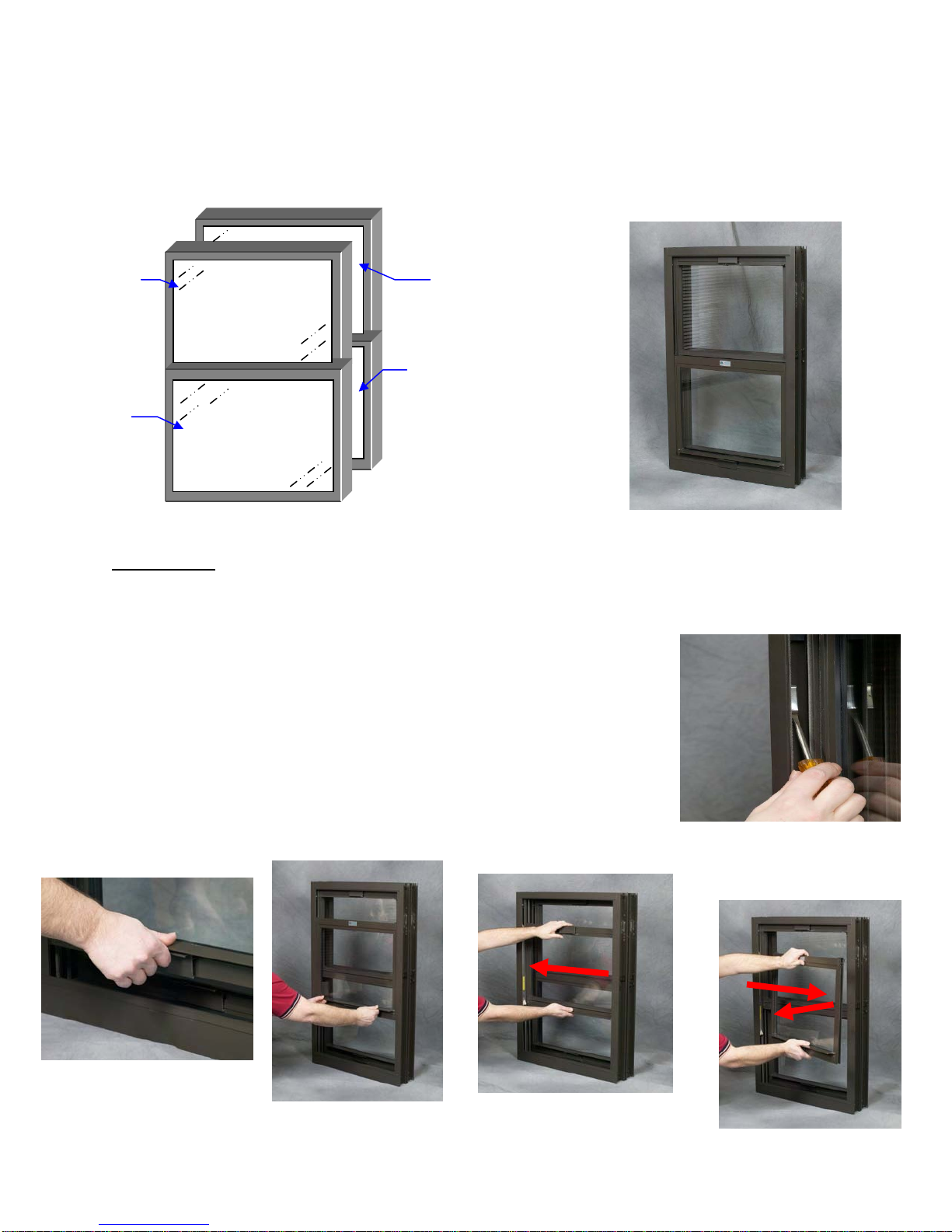

There are several elements the homeowner should pay attention to when cleaning and maintaining their

Graham window or door. These elements are:

•The cleanliness of the aluminum, glass, and screen

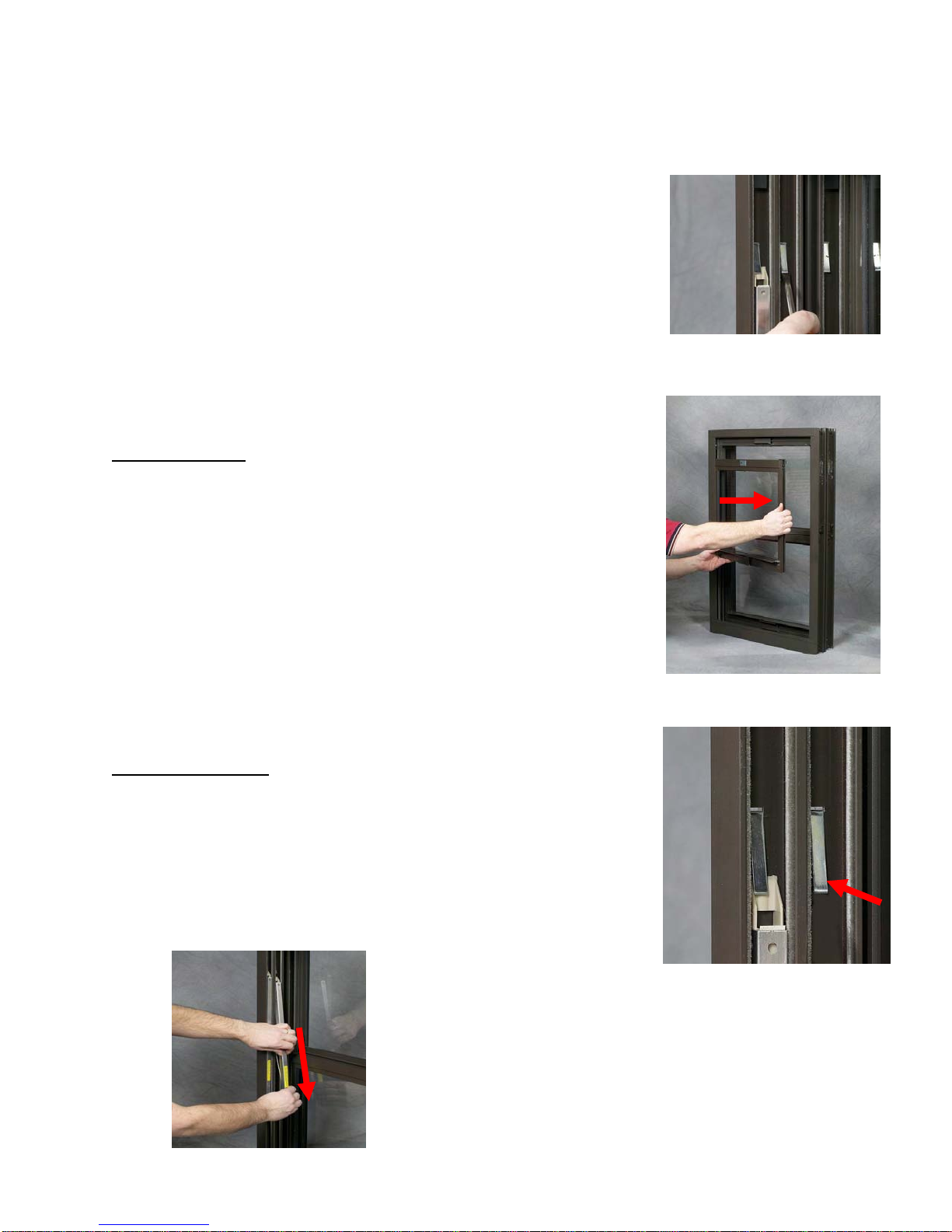

•The operability of vents and sashes

•Effectiveness of the water drainage system

•Understanding of condensation and humidity

Cleanliness of the Aluminum, Glass, and Screen

In order to extend the life of your window, it is very important to keep it clean. Many kinds of debris and

dirt build-up can harm your window and decrease its durability. The aluminum should be cleaned on a

regular basis to prevent a build-up, which could be difficult to remove later. Although this sounds like a

difficult task, it really is quite easy to clean the aluminum surface with little effort. In most cases, a heavy

rain is sufficient to clean the exterior side of the window.

Normal Maintenance for Aluminum Painted Surfaces

The painted surface provided will not normally show an appreciable amount of dirt collection. Very often,

rainfall may be sufficient to keep the exterior surface clean. In most geographic locations dirt or soil will

not have a detrimental effect on the coating, but cleaning may be desirable for appearance sake. Graham

recommends following AAMA publication No. 610.1-1979 “Voluntary Guide Specification for Cleaning

and Maintenance of Painted Aluminum Extrusions and Curtain Wall Panels” for maintaining the

aluminum finish. A copy of that document can be found in Appendix 1 of this manual.

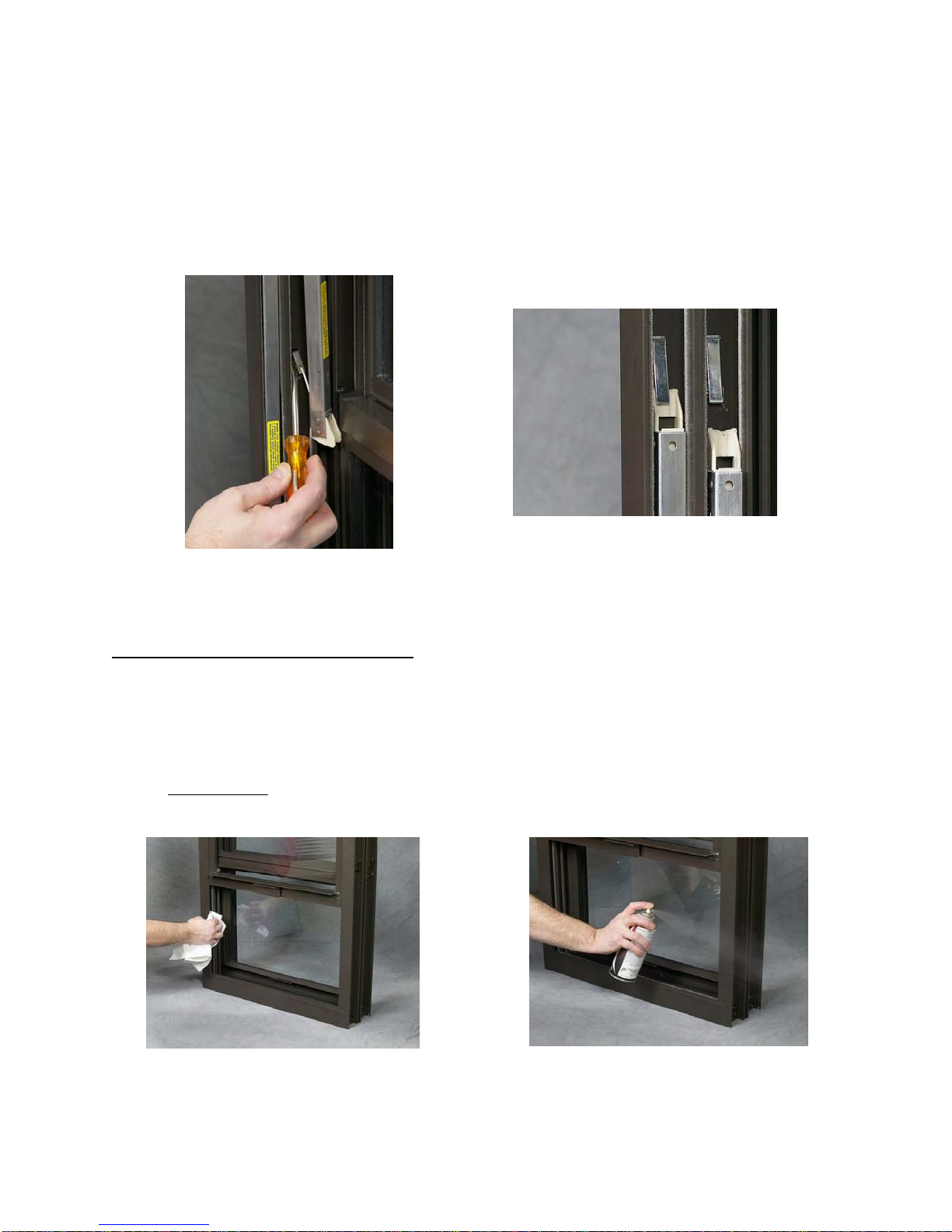

Normal Maintenance for Glass

Clean the glass using standard glass cleaner such as Windex®. Do not use abrasive cleaners, as it will

scratch the glass. Decals and dried debris can be removed with a new single edged razor blade, wetting

the glass first with glass cleaner.

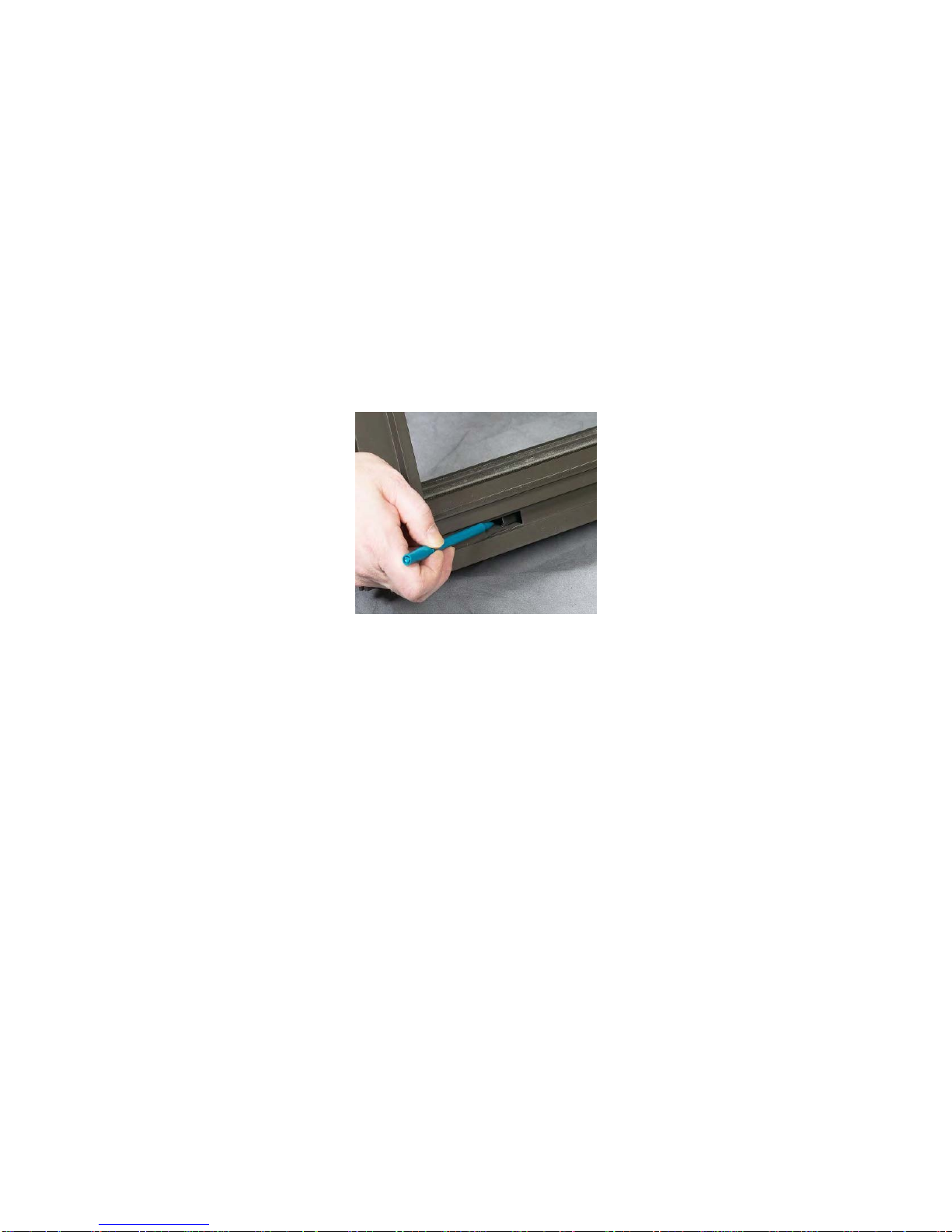

Normal Maintenance of the Screen

To clean the screens, simply hose them off with water. For built-up dirt, you can use a mild soap and

sponge, then rinse thoroughly. Do not use abrasive cleaners. Damaged screen mesh can be replaced by the

owner or by most local hardware shops. Do not use aerosol cleaning agents on screens, as certain

propellants in the cleaners can cause damage to the molded corner parts.