3

Operating Instructions and Parts Manual

12N408,12N409,12N410

12N411,12N412,12N413

Setup and Installation

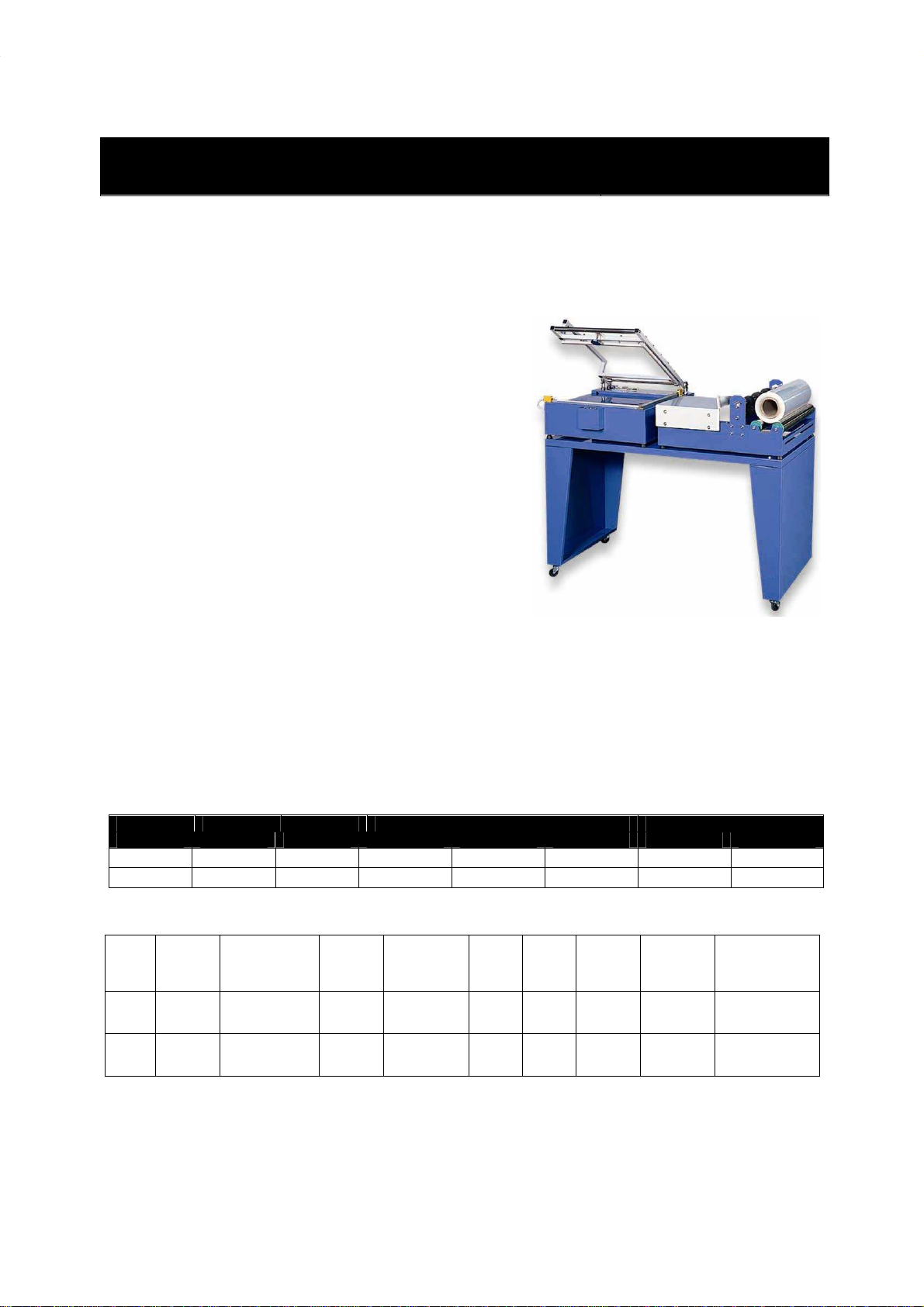

Carefully remove the outer carton and unpack the

legs, casters, and assembly hardware.

Figure 1

1

In an open workspace, attach legs and casters with

hardware provided.

Select an area for use that is open and free from dust,

flammable materials, or corrosive materials. Position

the sealer table in place so power connections may

be made.

Set the L-sealer on the left side of the work table and

place the film roll holder on the right side.

Plug the L-sealer into a dedicated 115V circuit.

Loading the Shrink Film

1. Most shrink films are centerfolded to allow the

film to envelop the product. Place the roll of film

on the rollers with the fold away from the operator.

2. Run the film through the perforation wheels.

Perforation will eliminate “pillowing” during later

heat shrinking steps but will not be visible after

heat shrinking.

3. Separate the fold, running the upper layer over

the raised platform on the roller table and the

lower layer beneath it.

4. On the L-sealer, adjust the work table height by

lifting up and to the left. The table height should

be set so half the package is above the sealing

element and half is below. The sealer table

should be lower for taller packages.

Operation

NOTE: Keep work area clear of obstructions.

NOTE: Before each use, check the Teflon® cloth and

silicone rubber bar. Replace if worn or damaged.

NOTE: Adjust the sealing timer to the lowest setting

that produces a good seal. Too high of a setting will

produce a poor seal and shorten heating element life.

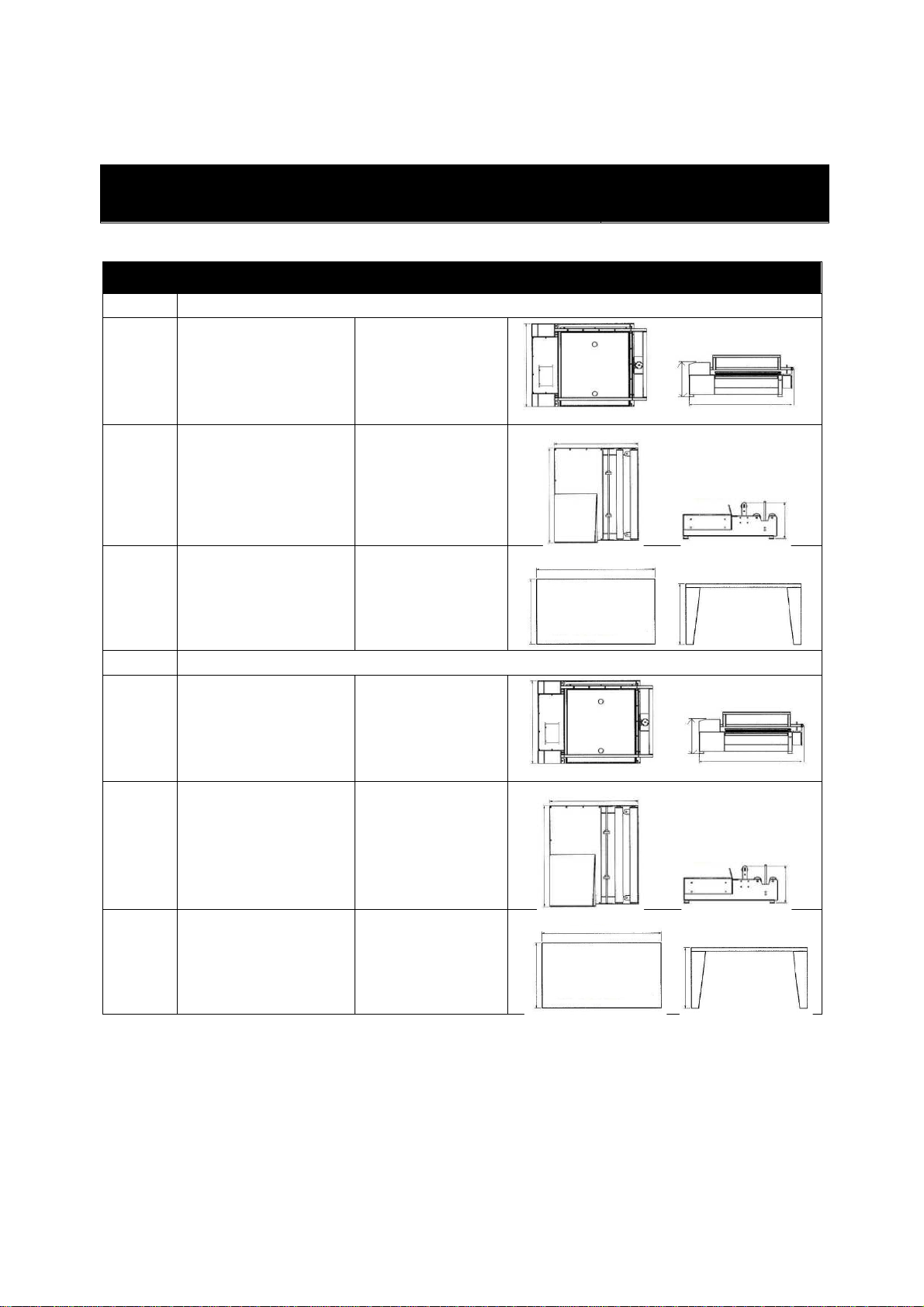

Figure 2

○

1

○

2

○

3

○

4

○

5

○

6

No.

Panel Function

1 Release LED

Indicates heating/cooling

cycle is still in process.

2 Heat LED Indicates heating element is

on and sealing.

3 Circuit

Breaker Press to reset and consider

moving to a dedicated circuit.

4 Release

Timer Adjusts cooling time after the

heat seal is made.

5 Heat Timer Adjusts heating time.

6 Power Powers all functions.

1. Turn on main power.

2. Feed film into sealing area

and press firmly down

on the bar to create an initial seal. This will serve

to seal the left side of the film, as well as test the

sealing settings.

3. When the bar is pressed down, the Heat LED

and Release LED will come on. The Heat LED

light will turn off as the cooling cycle begins. The

Release LED will then turn off and an audible

indicator will coincide with the arm’s

electromagnet release. Raise the arm.