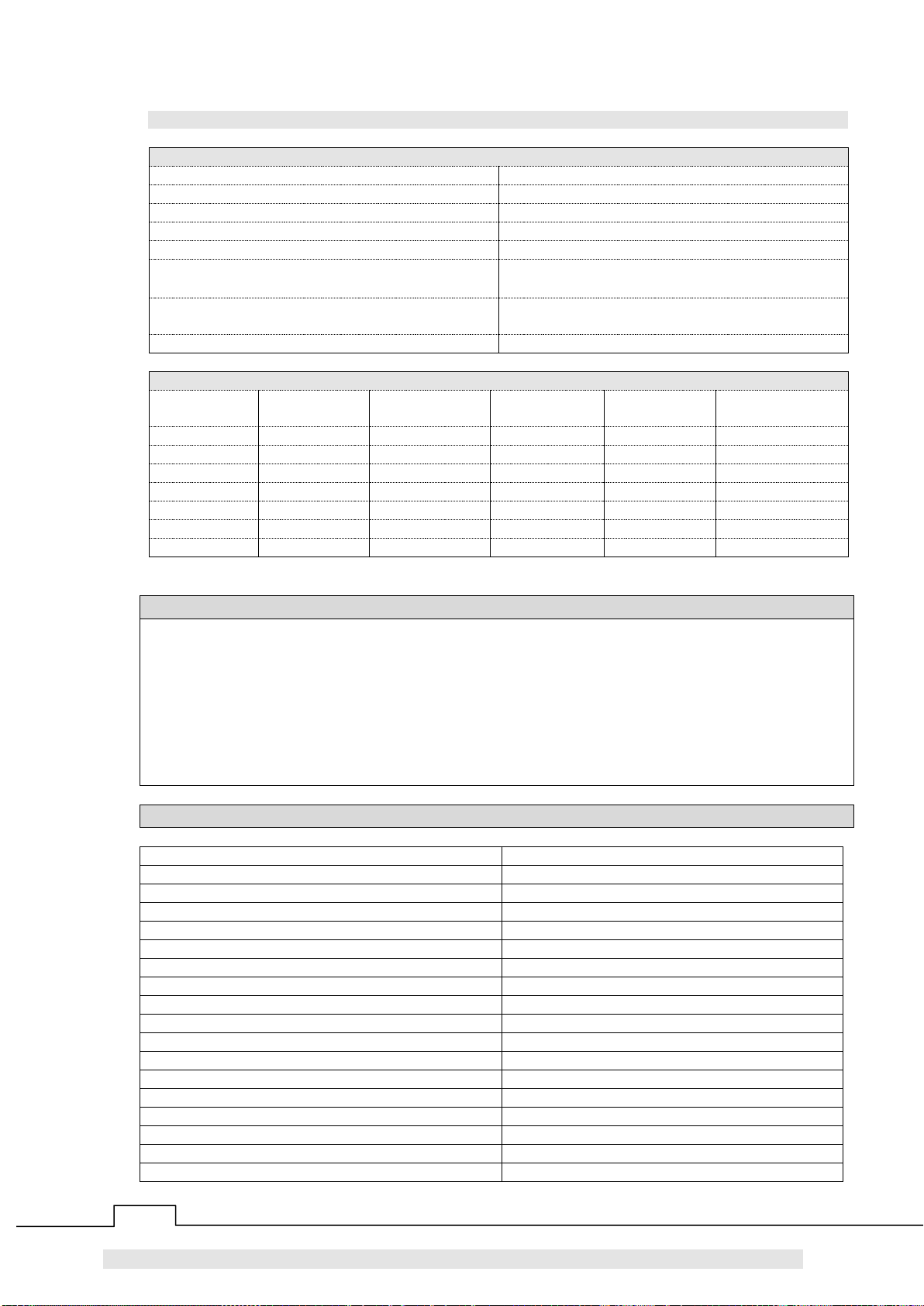

TABLE OF CONTENTS

1.

INTRODUCTION ..................................................................................................................................4

2.

CHECKLIST ..........................................................................................................................................5

3.

COMPONENTS ....................................................................................................................................6

4.

SPECIFICATIONS................................................................................................................................7

5.

WARNINGS...........................................................................................................................................7

6.

Recommended maximum moisture content for safe storage (wet Basis)....................................7

7.

INSTALLATION.....................................................................................................................................8

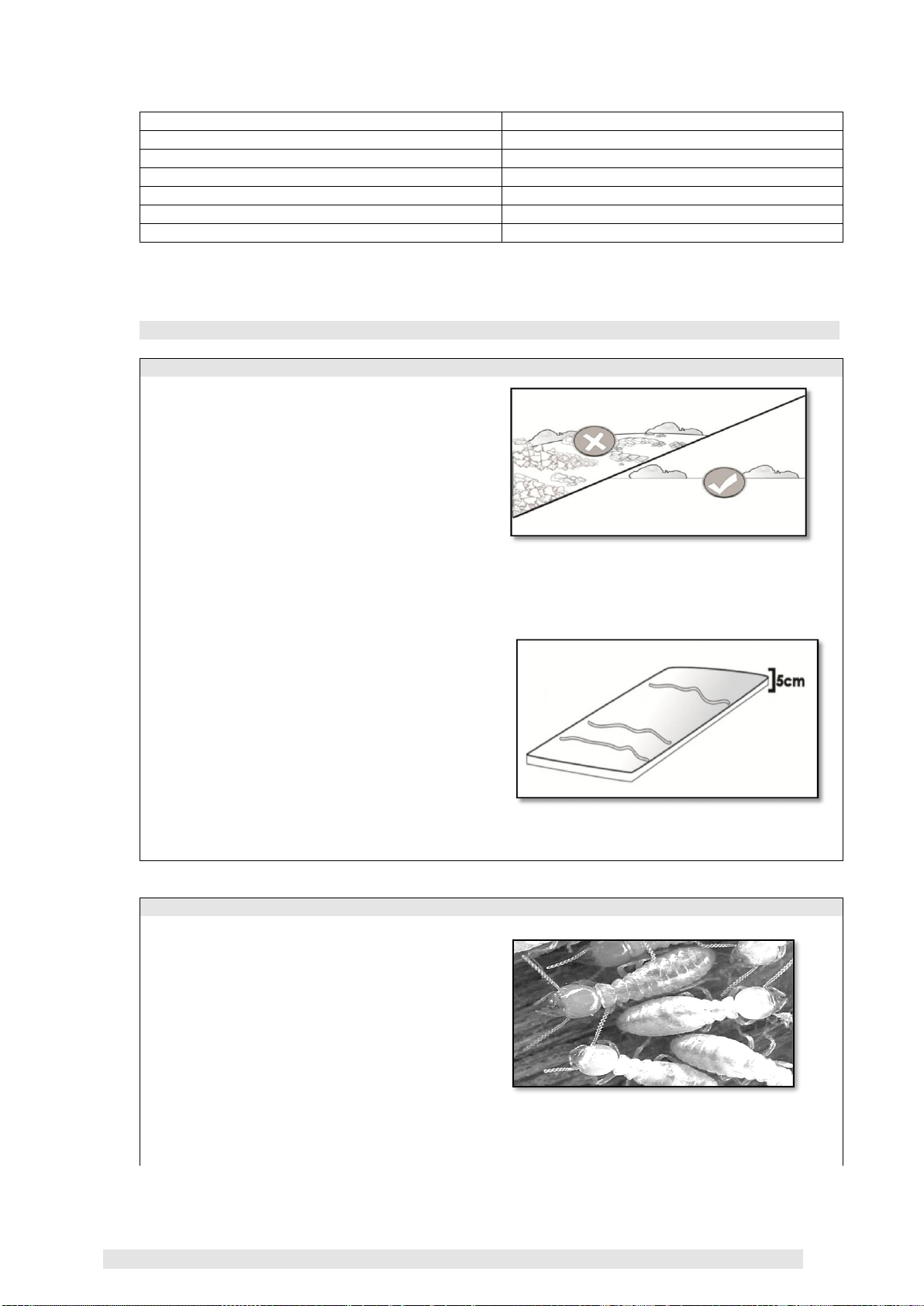

Site selection ....................................................................................................................................8

Termite Control.................................................................................................................................8

Rodent Control.................................................................................................................................9

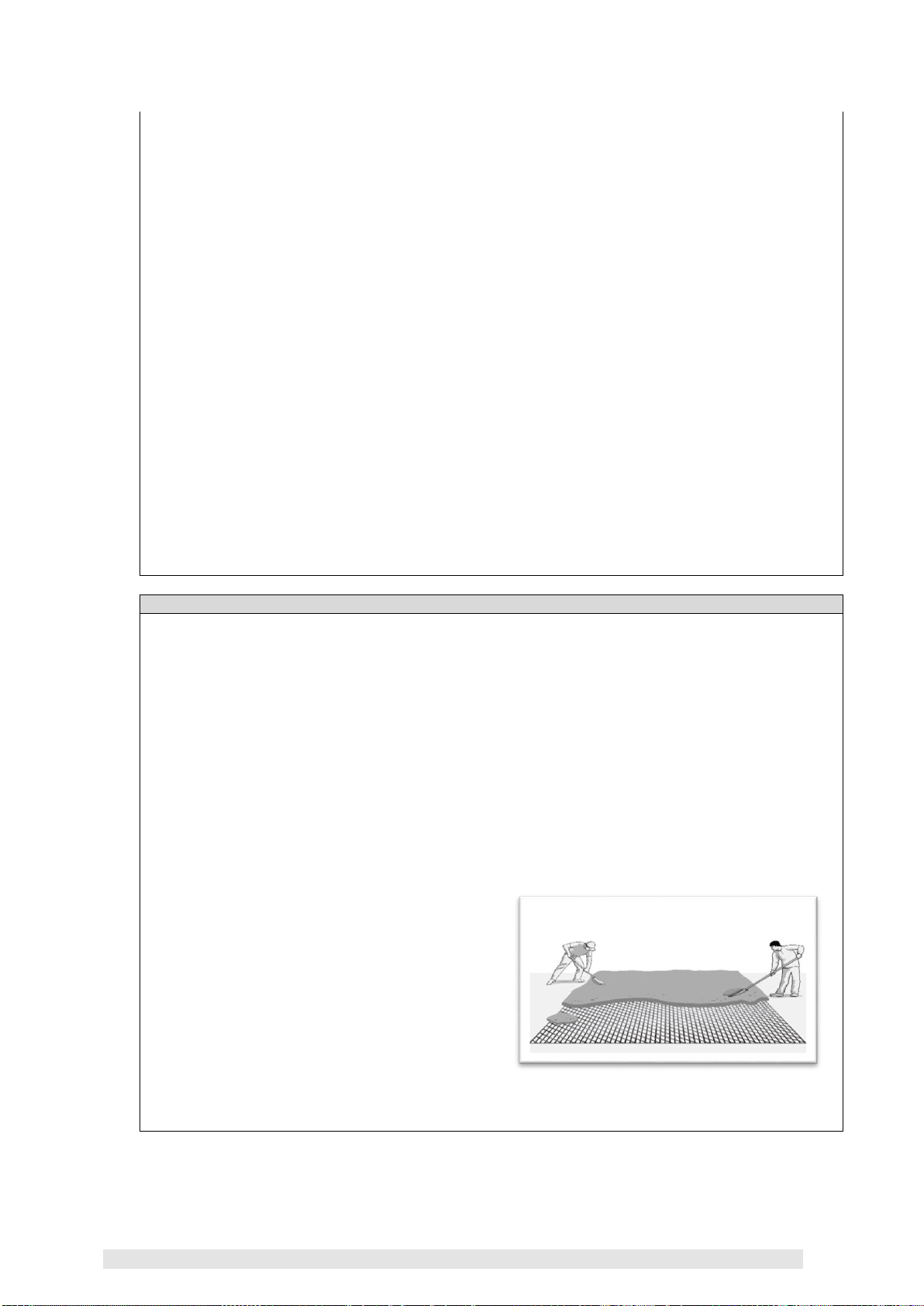

Loading............................................................................................................................................10

Positioning the top section............................................................................................................11

Use of Desiccant (Calcium Chloride, CaCl2) - (Recommended)............................................11

Zipping.............................................................................................................................................12

Pressure Decay testing (PDT).....................................................................................................14

Tensioning of straps ......................................................................................................................14

Monitoring the oxygen level and Relative Humidity (RH%).....................................................15

Dismantling.....................................................................................................................................16

8.

PREVENTING CONDENSATION....................................................................................................17

Why does condensation occur?...................................................................................................17

Moisture content (MC) requirement for safe storage................................................................17

Setting-up the GrainShade™.......................................................................................................17

9.

MAINTENANCE AND CARE............................................................................................................18

Regular examination......................................................................................................................18

Physical inspection........................................................................................................................18

Repairing punctures and other damages...................................................................................19

Cleaning top and bottom sections...............................................................................................19

Folding.............................................................................................................................................19

Safekeeping....................................................................................................................................20

Platform installation of rodent guard (RG)..................................................................................20

Recycling.........................................................................................................................................21

10.

FREQUENTLY ASKED QUESTIONS AND ANSWERS ..............................................................21

11.

WARRANTY CLAUSE.......................................................................................................................23