9

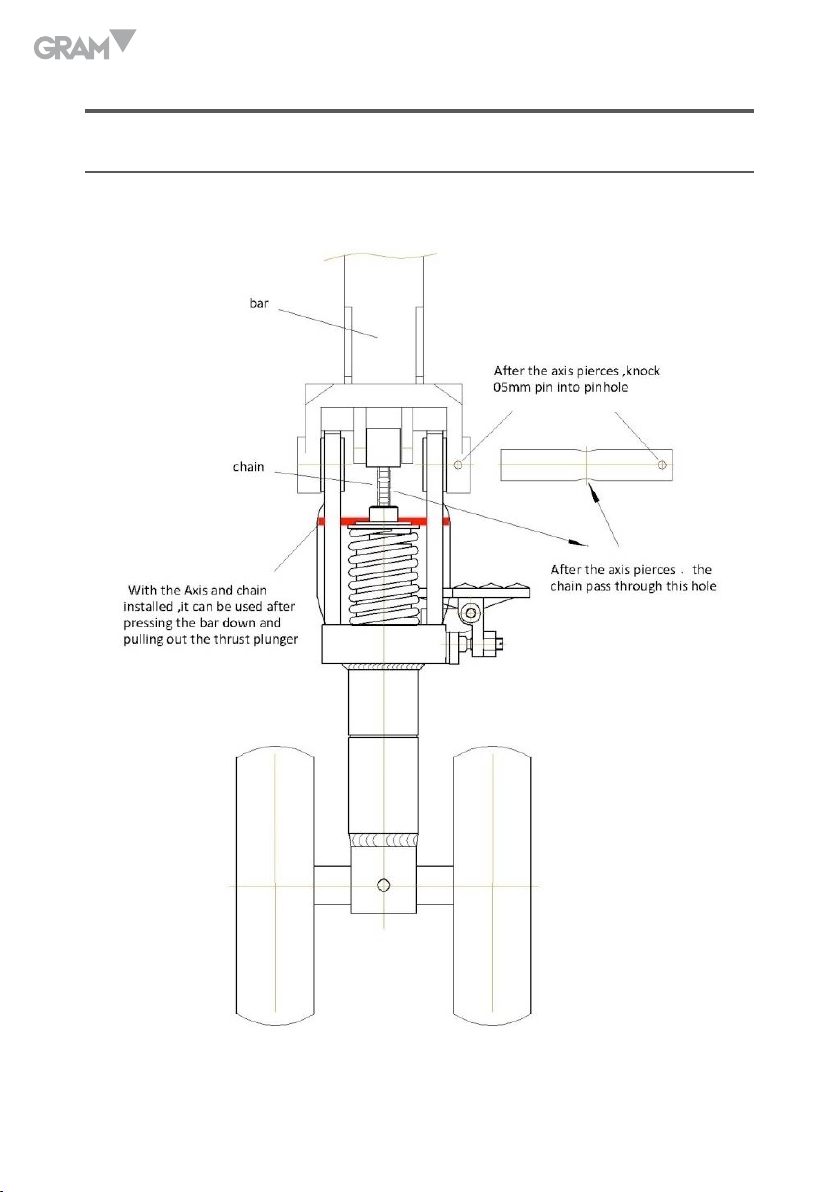

REGULATION OF THE FINGERLIKE

Regulation of the fingerlike handle’s three positions (ascend, middle,

descend).

On the pallet truck, you will see the fingerlike handle, which can be operated

on three positions:

Ascend --

Middle --

Descend --

When the operation has been completed, the handle should be put on the

middle position. The position of the fingerlike handle has been adjusted

before leaving factory, and if you need to change it, please do as the following

steps:

• If you push the handle down in the “middle” position, the fork rises,

please turn the screw round unloading board clockwise until the fork

does not ascend when you press the handle.

• If you push the handle down in the “middle” position, the fork declines

please turn the screw round on the unloading board anti-clockwise until

the fork does not descend when you press the handle.

• With the fingerlike handle in the “descend” position, the fork does not

descend, please turn the screw round on the unloading board clockwise

until the fork descend with the handle on that position. Then according

to 3.1 and 3.2, Check the middle (running position)to ensure the screw in

the right position.

• With the fingerlike handle in the “ascend” position, the fork does not

rise, please turn the screw round on the unloading board anti-clockwise

until the fork ascend with the handle on that position.