Blue Giant BG2-72 User manual

OPERATOR’S MANUAL

BG2-72 LOW LEVEL ORDER PICKER

ISSUE DATE: March, 2020 REV.0 (PART # 038-xxxE)

WARNING

Do not operate or service this product unless you have read and fully

understand the entire contents of this manual. Failure to do so may result in

property damage, bodily injury or death.

ACTUAL PRODUCT MAY NOT APPEAR EXACTLY AS SHOWN

A

WARNING

Do not operate this truck unless you have been authorized and trained to do so, and have

read all warnings and instructions in Operator's Manual and on this truck.

Do not operate this truck until you have checked its condition. Give special attention to

tires, horn, lights, battery, controller, lift system (including forks or attachments, chains,

cables and limit switches), brakes, steering mechanism, guards and safety devices.

Operate truck only from designated operating position. Never place any part of your body

into the mast stru cture, between the mast and the truck, or outside the Operator's platform.

Be sure any operator personal safety systems (guardrails, safety belts, harnesses, lifelines ,

etc.) are in place, properly worn and connected . Utilize additional protective fall restraint

equipment as applicable.

Observe appllcable traffic regulations. Do not carry passengers. Yleld right of

way

to pedestrians.

Slow down and sound horn at cross aisles and wherever vision is obstructed.

Start, stop, travel, steer and brake smoothly. Slow down for turns and on uneven or slippery

surfaces that could cause truck to slide or overtu rn.

Use special care when traveling without load as the risk of overturn may be greater.

Travel with lifting mechanism as low as possible. Always look in direction of travel and

keep a clear view.

Use special care when operating on ramps - travel slowly, and do not angle or turn.

Travel with lifting mechanism uphill.

Do not overload truck. Check nameplate for capacity and load center information .

Before lifting, be sure load is centered, forks are completely under load, and load is as far

back toward operator's platform as possible.

Do not handle unstable or loosely stacked loads. Use special care when handling long,

high or wide loads, to avoid losing the load, striking bystanders, or tipping the truck.

Do not handle loads when top of tiered load is more than 120 inches above the ground.

Ensure there is proper protection against falling objects from adjacent high stack areas.

Elevate forks or other lifting mechanism only to pick up or stack a load.

Watch out for obstructions, especially overhead.

Do not lift other personnel. Never transport personnel on forks.

Do not allow anyone to stand or pass under load or lifting mechanism.

When leaving truck, neutralize travel control, fully lower lifting mechanism and set brake.

When leaving truck unattended , also shut off power.

PROPOSITION 65

WARNING

1n accordance to

California Health & Safety Code Sections 25249.5 et. seq.

this warning is to let you know that this product can expose

yo u to chemicals known to the state of California to

cause cancer, birth defects and other reproduct ive harm .

For more information visit : www.p65warn ings.ca.g ov

FOREWORD

As a lift truck operator, you are

responsible for a machine that is

useful, powerful, and can be

hazardous if not operated as

described. Your Blue Giant truck

may weigh more than some cars,

depending on the model. Observing

and practicing the safety warnings

in this manual cannot be

overemphasized. Just knowing the

warnings, however, is no substitute

for common sense. Focusing on the

task at hand will, in almost all cases,

prevent accidents. Think of the truck

as your own. In this way you will learn

its capabilities and limitations.

This manual is intended to

remain with the truck at all times as a

handy

reference guide to operation. Detailed

maintenance procedures are found in

the parts and service manual for the

specific truck model, and aretobe

performed only bya qualified

technician. For further

information on obtaining a

complete parts and service manual,

see page 20 of this manual.

The operator who knows his truck will

learn to spot problems as they

develop. This is accomplished by

performing the Daily Checks and

reporting any problems to the

designated authority.

TABLE OF CONTENTS

SAFETY SYMBOLS .....................................................................

GENERAL DESCRIPTION............................................................ 2

LOAD CAPACITY ............................................................................. 4

BEFORE OPERATION ..................................................................... 5

Operator Checks ............................................................. 6

CONTROLS................................................................................... 7

INSTRUMENT PANEL...................................................................... 9

OPERATION.................................................................................. 11

Driving Procedures. ........................................................ 11

Stopping Procedures...................................................... 12

Picking Up A Load. ......................................................... 12

Transporting Loads......................................................... 12

Placing Loads.................................................................. 13

Overhead Maintenance................................................... 13

Parking. ............................................................................ 13

Moving A Disabled truck ................................................ 13

NOTICE - OBTAINING A PARTS AND SERVICE MANUAL ....... 20

2

SAFETY SYMBOLS

WARNING and CAUTION are both signal words intended to alert the viewer to

the existence and relative degree of a hazard. They are both preceded by a safety

alert symbol consisting of an exclamation mark enclosed by a triangle.

A Warning indicates a hazard which could result in injury or death if proper

precautions are not taken.

A Caution indicates a reminder of routine safety practices.

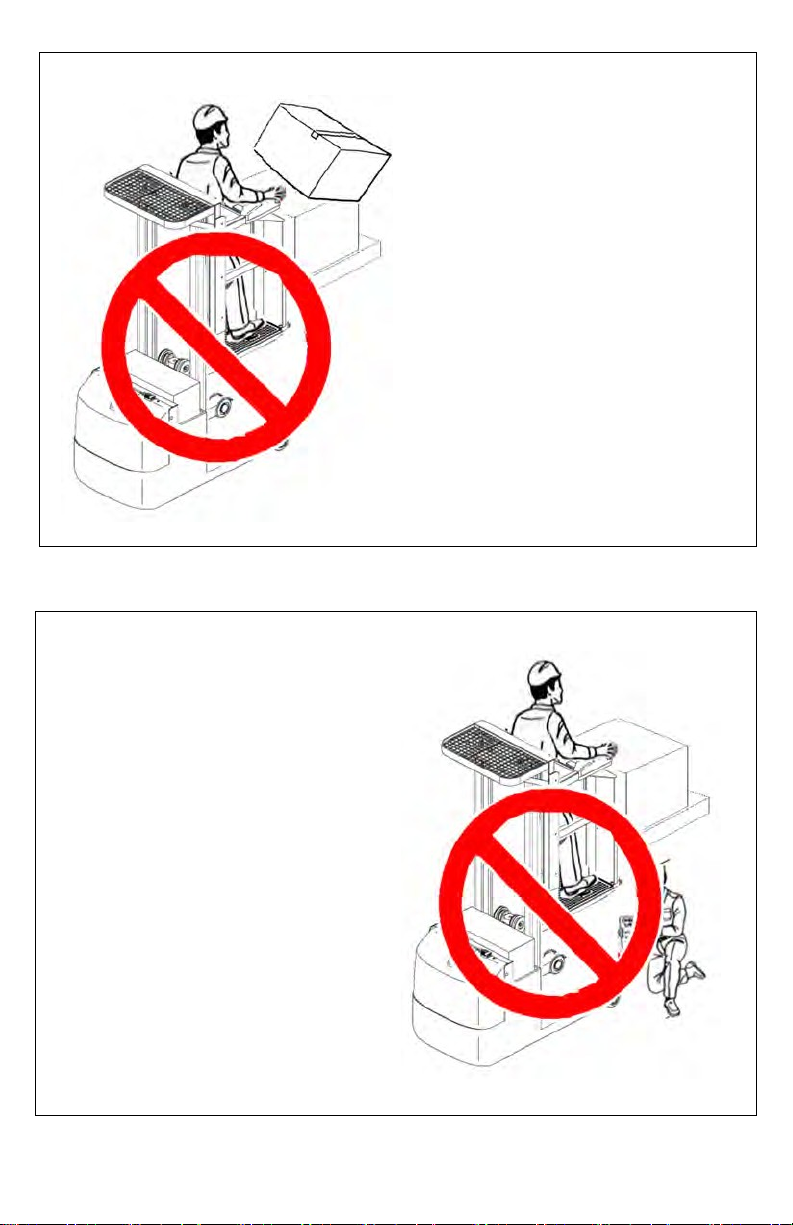

A prohibition slash (circle with diagonal slash through it) indicates a procedure or

action that should not be performed under any circumstances, as both personal

injury and/or damage to equipment will result.

GENERAL DESCRIPTION

The self-propelled lifts and

transports the operator (on the

platform portion of the lift carriage)

and the payload (on forks or optional

payload platform). This permits

efficient selection and moving of

materials in any area or at any level

of the warehouse or storeroom.The

design permits one man to perform

all operations of selecting the

stock, driving the truck, and replacing

the stock at the designated place.

The battery-powered truck is quiet

and without exhaust fumes,

allowing operation in closed areas

without special provisions for

ventilation.

The truck can be driven with the

platform raised or lowered; however

the speed is restricted above 15”.

On demand power steering makes the

truck highly maneuverable.

The control arms are used to operate

the work truck and provide operator

safety.

The operator platform contains the

deadman foot switch which must be

depressed for the truck to operate.

The model number will be found on

the name plate along with the serial

number, lifting capacity, and load

center.

Name Plate

3

WARNING:

This truck is equipped with a battery. Read and heed the warning decal located

near the battery. An example is shown here:

4

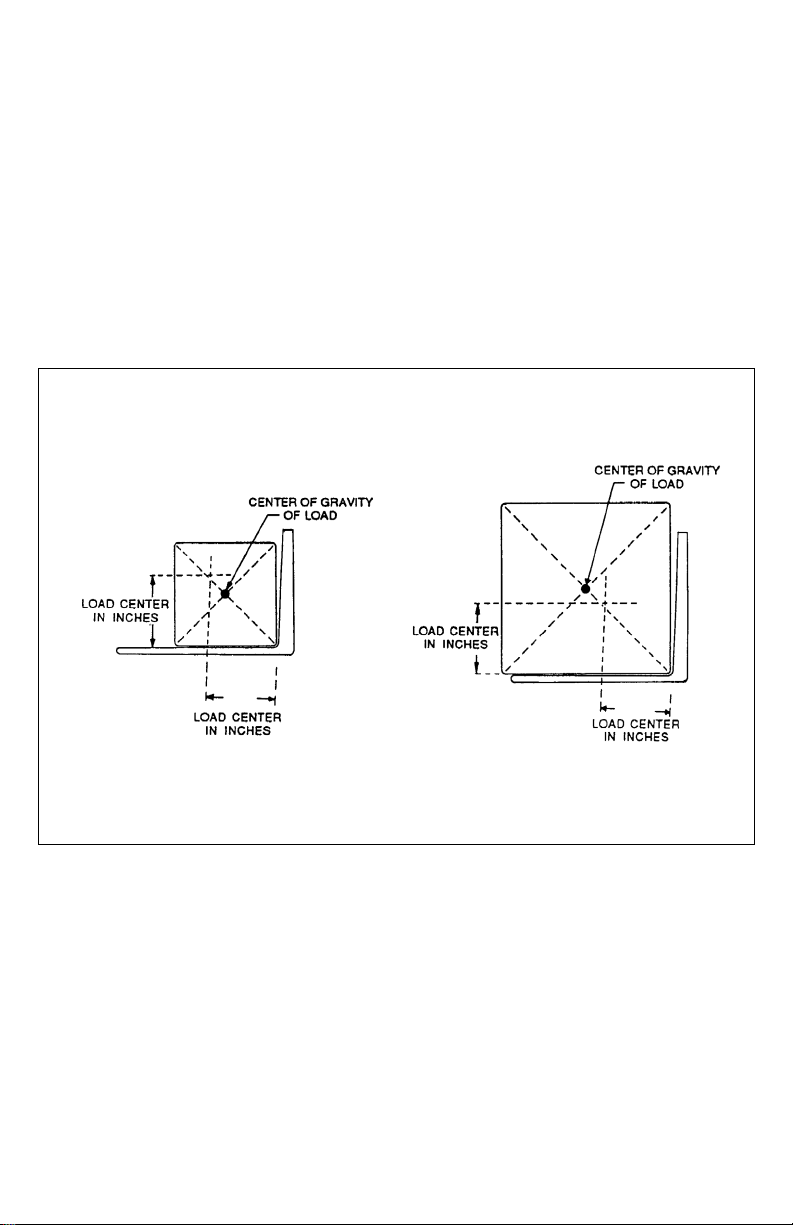

LOAD CAPACITY

Do not overload truck. Check name

plate for load weight capacity and load

center information.

The load capacity depends on the

load center. The load maximum

capacity listed on the capacity plate

assumes a uniform load whose center

is at 1/2 the length of the fork and

centered between the forks. The

maximum load capacity isreduced

when

the load center exceeds 1/2 the length

of the forks or is not centered between

the forks. The fork length and wheel

base must be adequate for the skid or

bin to be handled.

Note that a truck in motion is less

stable than a standing truck. Ifyou

are not sure that the truck can lift a

certain load, consult your supervisor

or the designated authority.

Load Center

R3814

5

R6235

BEFORE OPERATION

The table on page 6 covers important

inspection points on trucks which

should be checked prior to operation.

Depending on use, some trucks may

require additional checks.

The illustration below shows a sample

format for an Operator Checklist, which

can be modified as necessary to fit your

operation.

WARNING:

Periodic maintenance of this

truck by a QUALIFIED SERVICE

TECHNICIAN is required.

WARNING:

A QUALIFIED SERVICE TECHNICIAN

should check the truck

monthly for proper lubrication,

proper fluid levels, brake

maintenance, motor

maintenance and other areas

specified in the parts and

service manual maintenance

section.

WARNING:

If the truck isfound tobeunsafe

and inneed ofrepair, or

contributes to an unsafe

condition, report it immediately

to the designated authority. Do

not operate it until it has been

restored to a safe operating

condition. Do not make any

unauthorized repairs or

adjustments. All service must be

performed bya qualified service

technician.

Electric Truck

Daily Operator Check-Off List

Date Operator

Tru ck No. Model No.

Dept. Shift

Reading Dr i ve Hoist

Sample of Operator Check List

Check

O.K. ( )

Need Maintenanc e

Tir es

Load Wheels

Horn

Lift Lower Control

Attachment Operation

Forward & Rev erse Control s

Steering

Electrical Brakes

Hydraulic Leaks, Cylinders,

Valves, Hos es, Etc.

6

Operator Checks

ITEM

PROCEDURE

Transmission and hydraulic

systems

Check for signs of fluid leakage.

Forks and rear tray

Check for cracks and damage; that they are

properly secured.

Chains, cables and hoses

Check that they are in place, secured

correctly, functioning properly and free of

binding or damage.

Control arms and guard rails

Check that truck operation is disabled when

arms and guard rails are raised.

Safety warning label and

nameplate

Check that warning labels, nameplate, etc.,

are in good condition and legible.

Horn and flashing lights

Check that horn sounds when operated and

flashing lights are operable.

Steering

Check for binding or looseness when steering.

Travel controls

Check that travel control on right control arm

operates in all speed ranges in forward and

reverse.

Wheels

Check drive wheel for cracks or damage.

Move truck to check load wheel for freedom of

rotation.

Hydraulic controls

Check operation of lift and lower to their

maximum positions.

Emergency power discon-

nect switch

Check that brake actuates when emergency

power disconnect switch is depressed.

Battery disconnect

Check that battery can be disconnected and

reconnected. Check for connector damage.

Speed limit switches

Allow for enough space to operate truck in all

speeds. Test drive the truck to check for speed

reductions when elevated.

Platform Operation

Check that allcontrols in the platform

operating compartment are operational.

7

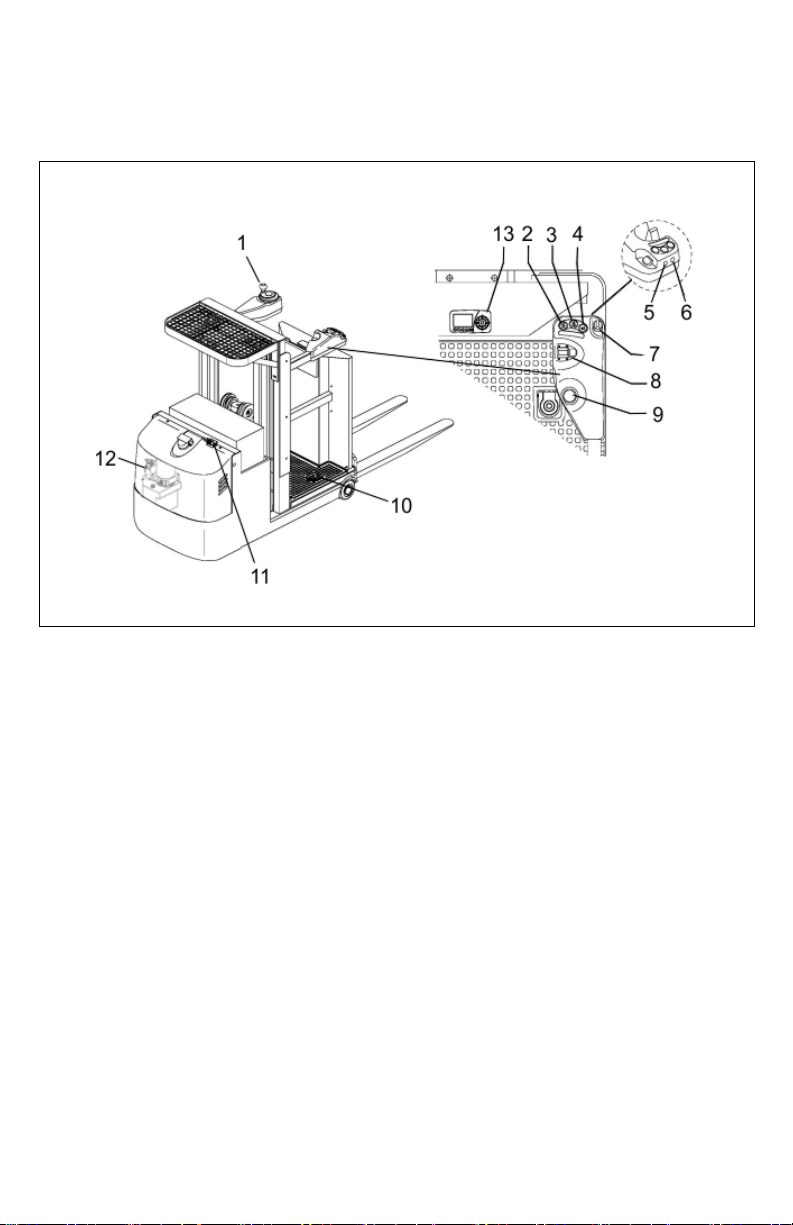

CONTROLS

Refer to the following illustration for

the location of the controls.

Controls

STEERING CONTROL (1)

This control is operated in the

conventional manner. Drive wheel

direction is also indicated on the

instrument panel.

OPERATOR PLATFORM LIFT (2)

To raise the operator platform, push

and hold this button until the desired

height is reached. Guard rails need to

be in the lowered position and

deadman footswitch needs to be

engaged for travel and lift.

OPERATOR PLATFORM LOWER

(3)

To lower the operator platform, push

and hold this button until the desired

height is reached. Guard rails need to

be in the lowered position and

deadman footswitch needs to be

engaged for travel and lift.

HORN BUTTON (4)

Sounds the horn.

8

FORK LOWER BUTTON (5)

To lower the forks, push and hold this

button until the desired height is

reached. Guard rails need to be in the

lowered position and deadman

footswitch needs to be engaged for

travel and lift.

FORK LIFT BUTTON (6)

To lift the forks, push and hold this

button until the desired height is

reached. Guard rails need to be in the

lowered position and deadman

footswitch needs to be engaged for

travel and lift.

KEY SWITCH (7)

The key switch has two positions,

ON and OFF. Remove the key to

prevent unauthorized use.

TRAVEL SWITCH (8)

This switch controls forward, neutral

and reverse travel. Travel direction is

also indicated on the instrument

panel.

EMERGENCY POWER

DISCONNECT SWITCH (9)

Pushing down the emergency power

disconnect switch disconnects the

main power, deactivates all electrical

functions, causing the truck to brake

automatically.

DEADMAN SWITCH PEDAL (10)

Operator must stand on this pedal to

activate the controls.

BATTERY DISCONNECT (11)

The battery disconnect can beused to

cut off all power to the truck. It is also

used to connect the batteries to the

battery charger.

EMERGENCY LOWERING BUTTON

(12)

Press this button to lower the platform

in case of an emergency.

INSTRUMENT PANEL (13)

The instrument panelcontains the

following displays and controls:

9

INSTRUMENT PANEL

LOW BATTERY ALARM LED (1)

This LED lights when the measured

battery voltage is equal or less than

40% normal battery voltage.

FAULT ALARM LED (2)

When a fault is detected, this LED will

light. The display (7) will display the

warning and fault indication. Report

alarm to the designated authority and

do not use the truck until corrected by

a qualified mechanic.

TEMPERATURE ALARM LED (3)

When the temperature of the motor/

controller exceeds allowable range

(too high or low), the LED will

illuminater. Temporarily stop operation

until the temperature drops and

notify an authorized technician.

DEADMAN SWITCH ALARM LED

(4)

When the deadman switch pedal is

released, this LED will illuminate.

BRAKE ALARM (5)

This LED will illuminate when the

brake is applied.

FUNCTIONAL KEYS (6)

Use the left arrow button to adjust the

speed mode. Use the down arrow

button to switch the driving mode.

DISPLAY (7)

The display has the following

functions:

10

Driving Mode Display (4): The

truck can be operated in two driving

modes, high sped or crawl speed.

High Speed

Creep Speed

Display

Battery Indicator (1): The state of

charge is displayed by ten notches.

Each notch represents 10% of the

battery charge. For example, the

illustration shows the battery has

80% charge.

Information Display (2): Displays the

warnings and faults. Report warnings

and faults to the designated authority

and do not use the truck until

corrected by a qualified mechanic.

Speed Display (3): Indicates the

truck’s speed.

Speed Mode Display (5): There are

four speed ranges available in both

high speed driving mode and the

creep speed driving mode. Use the

“left function key to select the desired

mode. “1” indicates the slowest speed

while “4” indicates the highest speed.

CAUTION:

When the platform rises the

truck automatically enters crawl

speed.

Steering Display (6): One of nine

notches will indicate the steering

angle of the drive wheel.

11

OPERATION

Operation

DRIVING PROCEDURES.

The truck can be driven with the platform

raised or lowered; however, the speed is

restricted when the platform

is raised above a preset limit of 15”.

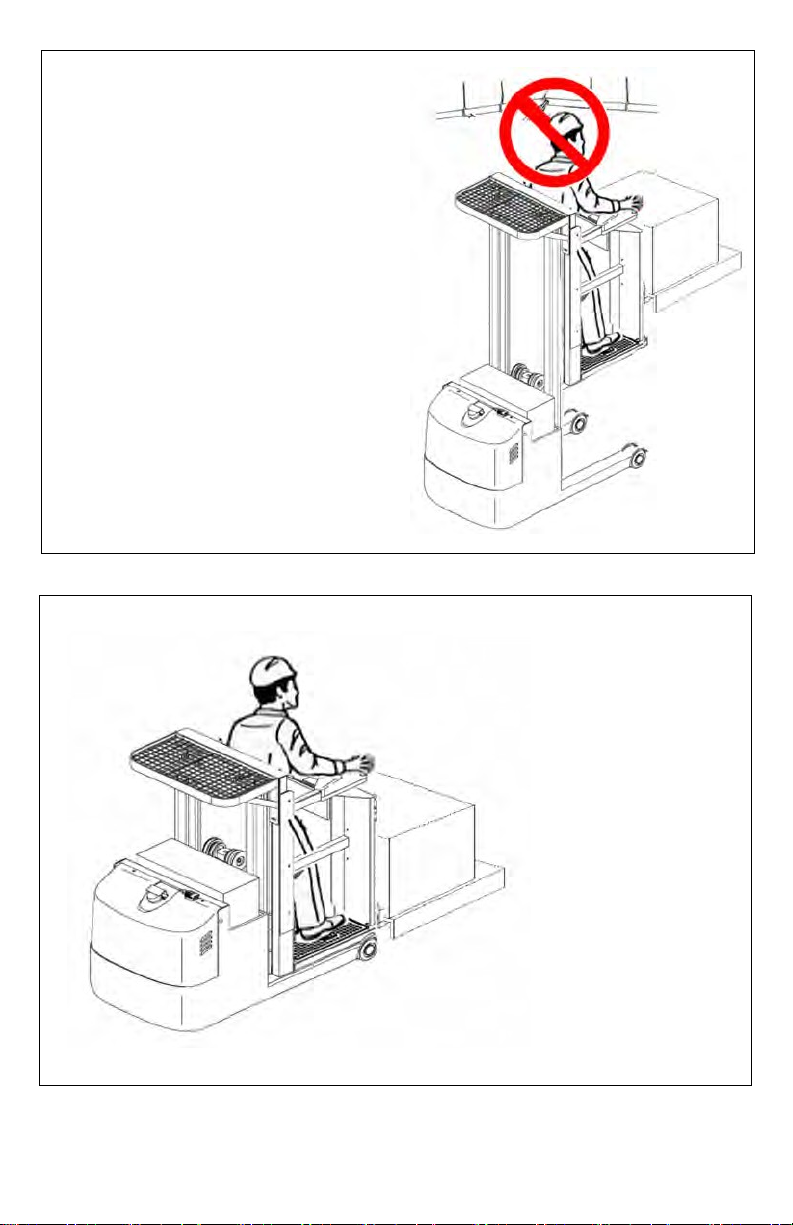

WARNING:

Do not leave the platform while

the operator platform is

elevated. Do not lean out from

the outside of a cage rail.

Climbing on the guard rails

and/or forks is strictly

prohibited and can lead to

severe injury or death.

WARNING:

Only one person is permitted in

the operator’s compartment at

all times.

Proceed as follows to start and stop

the truck.

1.

Step on the operator platform with

your backagainst the back rest.

2.

Lower the control arms and guard

rails.

3.

Turn on the keyswitch (7) and pull

up on the emergency power

disconnect switch (9).

12

4.

Step on the deadman footswitch

(10) to activate the electrical

controls.

5.

Select the speed mode using the

“left” function key on the

instrument panel (13).

6.

Using the steering control (1) to

steer the truck in the required

direction. Drive wheel directions is

indicated on the instrument panel.

7.

Using your right hand, move the

travel switch (8) to the desired

direction.

NOTE: The truck direction may be

reversed while moving. The

control will cycle the motor to

stop and then reverse in a

timed sequence without

danger to the equipment.

Exercise caution when doing

so, especially when

traveling at maximum speed.

Emergency Braking: To stop rapidly

when an emergency exists, press the

emergency power disconnect switch

(9).

WARNING: WARNING:

The truck is equipped with a

level sensor. When the truck is

elevated and on a slope greater

than 0.5 degrees, the level

sensor sounds an alarm

beeper. The truck is only to

be used indoors on a level

surface. This truck is not for

use on mezzannes or balcony

areas.

STOPPING PROCEDURES.

The brake pattern of the truck depends

largely on the ground conditions. The

driver must take this into account when

operating the truck. The driver must be

looking ahead when traveling. If there is

no hazard, brake moderately to avoid

moving the load.

The truck can brake in three different

ways:

Coasting Brake: release the

deadman switch pedal (10) and allow

the truck to coast to a stop.

Plugging: To stop faster, slowly move

the travel switch (8) to the opposite

direction.

Except in an emergency, do not

stop suddenly.

PICKING UP A LOAD.

The operator platform lift is used to

raise the platform to desired height for

picking the load. The fork lift is used to

adjust the load height to a comfortable

operator height.

1.

Drive the truck carefully up to the

storage location.

2.

Press and hold lift button (2) until

the platform reaches the desired

height.

3.

Adjust the forks to a comfortable

operator height using fork buttons

(5 and 6).

4.

Move the load from storage

location to the forks or rear tray.

5.

Press and hold lower button (3)

until the platform is completely

lowered.

TRANSPORTING LOADS.

1.

Always transport load with the

platform completely lowered.

13

2.

Always transport loads on the

forks or the rear tray.

3.

Always be prepared to brake.

Only stop suddenly in emergency

situations.

4.

Reduce speed intight areas.

PLACING LOADS.

1.

Drive the truck carefully to the

storage location.

2.

Press and hold lift button (2) until

the platform reaches the desired

height.

3.

Press and hold lift button (6) to

raise the load to a comfortable

operator height.

WARNING:

Ensure storage location is suit-

able for storing the load (size

and capacity).

4.

Move the load from the forks or

rear tray to the storage location.

5.

Press and hold lower button (3)

until the platform is completely

lowered.

OVERHEAD MAINTENANCE.

When performing overhead

maintenance, please ensure there

are no obstacles, beams or other

obstructions

before elevating lift. Always fully

lower the platform before moving to

the next maintenance position.

Ensure a safe workenvironment

before proceeding with maintenance

and never operate the truck outside.

PARKING.

When leaving the truck, it must be

securely parked even for a short time.

1.

Park the truck in its designated

parking area.

WARNING:

Do not park the truck on a

slope. The forks and platform

must be completely lowered.

2.

Lower the forks and platform

completely.

3.

Set the emergency power

disconnect switch (9) to apply the

brake.

4.

Turn keyswitch (7) to off position.

Remove the key for added

security.

5.

Pull out battery disconnect (11).

MOVING A DISABLED TRUCK

Do not attempt to move a disabled

truck; notify your supervisor or proper

authority.

14

The following operating instructions appear on the truck warning decal, which is

located on the operator platform.

Do not operate this truck

unless you have been

authorized and trained to

do so, and have read all

warnings and instructions

contained in this operator’s

manual and on this truck.

Read, understand and

comply with the information

on the truck’s nameplate

at all times.

Do not operate this truck until

you have checked it’s condition.

Give special attention to tires,

horn, lights, battery, controller,

lift system (including forks or

attachments, chains, cables and

limit switches), brakes, steering

mechanism, guards and safety

devices.

If you have any questions, notify

your supervisor or proper

authority

15

Operate truck only from

designated operating position.

Never place any part of your

body into the mast structure,

between the mast and the truck,

or outside the Operator's

platform.

Observe applicable traffic

regulations. Do not carry

passengers Yield right of

way to pedestrians.

slow down and sound

horn at cross aisles and

wherever vision is

obstructed.

16

Travel with lifting mechanism as

low as possible. Always look in

direction oftravel & keep a

clear view.

Do not handle unstable or loosely stacked

loads. Use special care when handling

long, high or wide loads, to avoid losing

the load, striking bystanders or tipping the

truck. When transferring loads to platform

or platform shelf, do not exceed capacity

ratings on truck nameplate. Ensure loads

are centered and do not contact any

obstructions in the trucks vicinity.

17

Elevate forks or other lifting mechanism

only to pick up or stack a load. Watch

out for obstructions, especially

overhead.

When using forks, space forks as

far apart as load will permit. Before

lifting, be sure load is centered,

forks are completely under load,

and load is as far back as possible

against load backrest.

18

Do not handle unstable or loosely

stacked loads. Use special care when

handling long, high or wide loads to

avoid losing the load, striking

bystanders, or tipping the truck.

Do not allow any one to stand or pass

under load or lifting mechanism.

Table of contents

Other Blue Giant Truck manuals