SIBS Fuso Canter Instruction manual

SIBS® 4 WORKSHOP MANUAL

FUSO CANTER

MAN-059 8 FEB 2017

2

1. Revision History

Revision

Issue Date

Author

Comments

1

1 Mar 2016

M. O’Driscoll

Initial Release

2

8 Feb 2017

M. O’Driscoll

Sections 14, 15, 16 and 17 updated with new service regime.

3

6 Apr 2017

M. O’Driscoll

Wiring and hydraulic sections updated with 24V details.

© Advanced Braking Pty Ltd, 2017.

All rights reserved. No part of this manual may be reproduced in any form or by any means without the prior written consent

from the copyright holder. While every attempt is made to ensure that the information in this manual is correct, no liability can

be accepted by the authors for loss, damage or injury caused by any errors in, or omissions from, the information given.

MAN-059 8 FEB 2017

3

2. Table of Contents

1. Revision History ....................................................................................................................................................................... 2

2. Table of Contents..................................................................................................................................................................... 3

3. Important Information ............................................................................................................................................................ 4

4. Terminology............................................................................................................................................................................. 5

5. Brake Description .................................................................................................................................................................... 6

6. Exploded Views & Parts Lists - Differential Brake Assembly ................................................................................................... 7

7. Wiring Diagram 12V............................................................................................................................................................... 10

8. Wiring Diagram 24V............................................................................................................................................................... 12

9. Pump Hardware Parts List 12V .............................................................................................................................................. 14

10. Pump Hardware Parts List 24V .............................................................................................................................................. 16

11. Installation –Driveline Brake (Light - Medium Trucks).......................................................................................................... 18

12. Installation –Hydraulic System ............................................................................................................................................. 21

13. Installation –Electrical System .............................................................................................................................................. 23

14. Pre-Service Inspection ........................................................................................................................................................... 27

15. Control System Setup ............................................................................................................................................................ 29

16. Service Schedule .................................................................................................................................................................... 30

17. Pre-Start Check ...................................................................................................................................................................... 31

18. Minor Service (100 hrs) ......................................................................................................................................................... 32

19. Major Service......................................................................................................................................................................... 34

20. Troubleshooting..................................................................................................................................................................... 39

MAN-059 8 FEB 2017

4

3. Important Information

This manual applies to the fourth generation Sealed Integrated Braking System (SIBS® 4) for Fuso Canter 4x4 Trucks. The manual

details how to install the SIBS® 4 system correctly to ensure optimum safety and performance. All information contained in this

manual is based on the latest SIBS® product information available at the time of publication.

This manual should be read in conjunction with the appropriate Fuso Canter vehicle manual for further information on removal

and installation of any standard Canter components.

While every effort has been made to address all aspects of installation and servicing, please advise Advanced Braking of any

omissions or suggestions on how this manual may be improved.

Advanced Braking Pty Ltd reserves the right to change the manual at any time without prior notice.

The most up to date version of the manual can be obtained by contacting the ABT Customer Service Manager.

The SIBS® and EMMA™ trademarks are owned by Advanced Braking Pty Ltd.

Street Address: Advanced Braking Pty Ltd

Unit 1, 3 McDonald Street West

Osborne Park WA 6017

AUSTRALIA

Postal address: PO Box 1177

Osborne Park WA 6916

AUSTRALIA

E-mail: sales@advancedbraking.com

Website: www.advancedbraking.com

Phone: +61 (08) 9273 4800

Fax: +61 (08) 9201 9986

MAN-059 8 FEB 2017

5

4. Terminology

ATF

Automatic transmission fluid

DPS

Door proximity system

Driveline Brake

Single brake unit acting on the rear axle differential

Emergency Brake

Brakes automatically applied in an emergency

EMMA™

Electronically Modulated Mechanically Applied

OEM

Original equipment manufacturer

Park Brake

Brakes applied independently of the service brake

PWI

Pad wear indicator

SIBS®

Sealed Integrated Braking System

SIBS®Cooling Fluid

Specially formulated cooling fluid for use in SIBS®brakes

MAN-059 8 FEB 2017

6

5. Brake Description

The Sealed Integrated Braking System (SIBS®) is a Spring Applied Hydraulic Release system operating in isolation from any other

braking system fitted to the vehicle. SIBS®has been configured for mounting to the driveline of light to medium goods vehicles.

The brake is bolted to the input side of the rear differential carrier. The torque generated by the brake is transmitted to the rear

wheels via the differential and axle shafts.

The SIBS® brake operates as a spring applied hydraulic release emergency driveline brake only. The hydraulic system has been

designed to modulate the application preventing shock loads damaging the driveline.

SIBS®is an enclosed single rotor high-speed disc brake. It provides greater reliability in a compact enclosed package. The brake is

designed for harsh mining environments and is able to be submerged for short periods without affecting operation.

Important:

1. The brake is intended as an emergency brake only for use in the event of a service brake system failure. The system

is not designed as an additional service brake.

2. Do not perform dynamic stops unless in an emergency situation. If the brake is used in an emergency situation it is

recommended to strip and inspect the brake and diff components.

3. The SIBS®Emergency Driveline brake is not designed as a vehicle retarder and should only be used in the case of an

emergency.

4. The SIBS®Emergency Driveline Brake System LV21 is designed for “off highway” use. Whilst it is possible to operate

the vehicle with the brake attached at highway speeds without damage, unintended application of the brake will

rapidly and effectively arrest the vehicle. ABT recommends that the brake is disabled for highway use by installing

the supplied retractor bolts. This recommendation applies to delivery of the vehicle to site and any other extended

“on highway” use.

WARNING:

The retractor bolts must be removed to re-commission the brake prior to the vehicle commencing service.

MAN-059 8 FEB 2017

7

6. Exploded Views & Parts Lists - Differential Brake Assembly

MAN-059 8 FEB 2017

8

ITEM

PART NO.

DESCRIPTION

QTY/ BRAKE

TORQUE

(Nm)

1

21-9008

BOLT DRIVE SHAFT

4

130

2

21-9010

NUT PINION

1

Ref. Canter manual

3

21-9009

WASHER DRIVE SHAFT

10

-

4

31-5015

NIPPLE GREASE

2

5

5

21-2010

YOKE DRIVE SHAFT

1

-

6

31-4013

SEAL V-LIP

1

-

7

25-2049

SEAL CASSETTE HOUSING

1

-

8

31-9000

CAP BLEED NIPPLE

4

-

9

31-5001

BLEED NIPPLE

4

15

10

31-5000

CONNECTOR HOSE EMMA

1

20

11

25-2039

PLUG DRAIN

1

20

12

30-2003

WASHER SEALING COPPER

2

-

13

31-5035

PLUG FILL

1

20

14

31-3001

PIN DOWEL

4

-

15

21-2001

HOUSING OUTER

1

-

16

31-2004

WASHER SEALING COPPER

2

-

17

21-2006

ADAPTER BLEED NIPPLE

2

20

18

31-2006

O-RING HOUSING

1

-

19

21-2005

CARRIER HOUSING SEAL

1

-

20

30-0059

BOLT SEAL CARRIER

4

10

21

25-4030

BRAKE PAD OUTER

2

-

22

25-2000

BRAKE ROTOR

1

-

23

25-4029

BRAKE PAD INNER

2

-

24

30-0020

BOLT BRAKE MOUNTING

6

100

25

21-2008

HOUSING INNER

1

-

26

31-5032

CONNECTOR BARB BREATHER HOSE

1

15

27

30-0003

BOLT BRAKE HOUSING

12

50

MAN-059 8 FEB 2017

9

28

21-2009

CAGE BEARING MODIFIED (FROM VEHICLE)

-

-

29

21-9006

SEAL PINION

1

-

30

31-2001

BACK-UP WASHER SMALL EMMA PISTON

4

-

31

31-2000

O-RING SMALL EMMA PISTON

4

-

32

31-2002

O-RING LARGE EMMA PISTON

4

-

33

31-2003

BACK-UP WASHER LARGE EMMA PISTON

4

-

34

25-2006

PISTON EMMA

4

-

35

31-0002

DISC SPRING

24

-

36

25-2061

SPRING COVER GASKET

1

-

37

25-2008

COVER SPRING EMMA

1

-

38

25-2040

PLUNGER PAD WEAR INDICATOR

1

15

39

25-2041

PLUG PAD WEAR INDICATOR

1

15

40

30-2005

WASHER PAD WEAR INDICATOR

1

-

41

25-2042

CAP PAD WEAR INDICATOR

1

10

42

30-2000

WASHER FLAT SPRING COVER

10

-

43

30-0001

SPRING COVER BOLT

10

60

44

31-5004

PLUG SPRING COVER

3

10

45

30-0028

RETRACTOR BOLT

4

80

46

21-5000

KIT SEAL

1

-

47

25-5047

KIT BRAKE PAD

1

-

48

21-5001

KIT MAJOR SERVICE

1

-

MAN-059 8 FEB 2017

10

7. Wiring Diagram 12V

TO SPEED SIGNAL

TO IGNITION

TO OIL PRESSURE

TO SEAT BELT

12V

MAN-059 8 FEB 2017

11

10A FUSE

30A FUSE

12V POWER

MAN-059 8 FEB 2017

12

8. Wiring Diagram 24V

TO SPEED SIGNAL

TO IGNITION

TO OIL PRESSURE

TO SEAT BELT

MAN-059 8 FEB 2017

13

MAN-059 8 FEB 2017

14

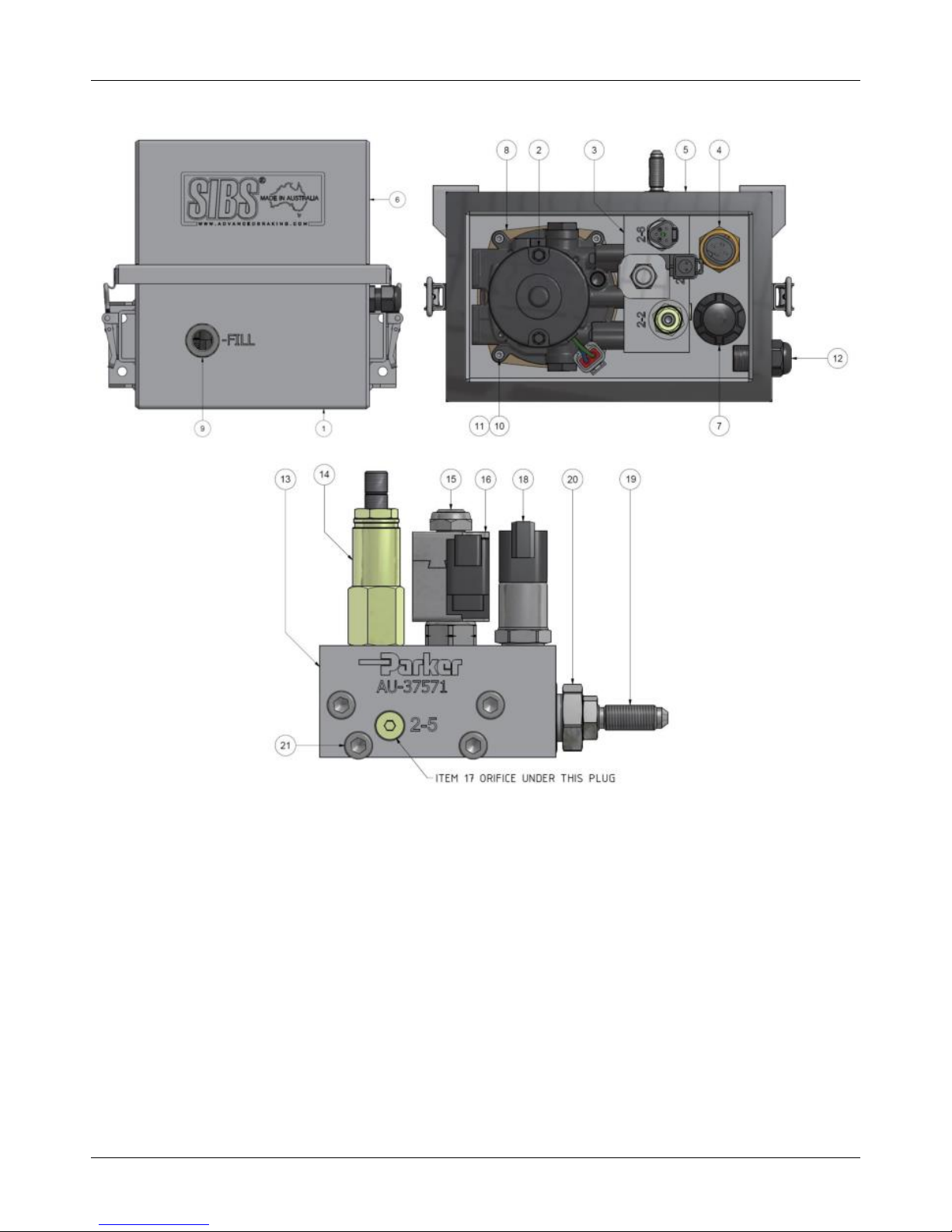

9. Pump Hardware Parts List 12V

MAN-059 8 FEB 2017

15

ITEM

PART NO.

DESCRIPTION

QTY/KIT

1

18-9015

ENCLOSURE BASE/RESERVOIR

1

2

18-9026

POWER UNIT 12V (PUMP + ADAPTER + MOTOR)

1

3

18-9014

MANIFOLD ASSEMBLY 12V

1

4

18-9027

LEVEL SENSOR

1

5

18-9028

ENCLOSURE GASKET

1

6

18-9028

ENCLOSURE LID

1

7

18-9024

FILL CAP

1

8

18-9029

POWER UNIT GASKET

1

9

18-9030

LEVEL WINDOW

1

10

18-9031

SCREW POWER UNIT

4

11

18-9032

WASHER SPRING POWER UNIT

4

12

18-9033

CABLE GLAND

1

13

18-9034

MANIFOLD BLOCK

1

14

18-9035

RELIEF VALVE

1

15

18-9036

SOLENOID VALVE

1

16

18-9021

COIL 12V

1

17

18-9037

ORIFICE 0.5mm

1

18

18-9017

PRESSURE SENSOR

1

19

18-9038

BULKHEAD FITTING

1

20

18-9039

ADAPTER FITTING MANIFOLD TO BULKHEAD

1

21

18-9040

SCREW MANIFOLD BLOCK

4

22

18-4033

MANIFOLD O-RING SEAL KIT

1

MAN-059 8 FEB 2017

16

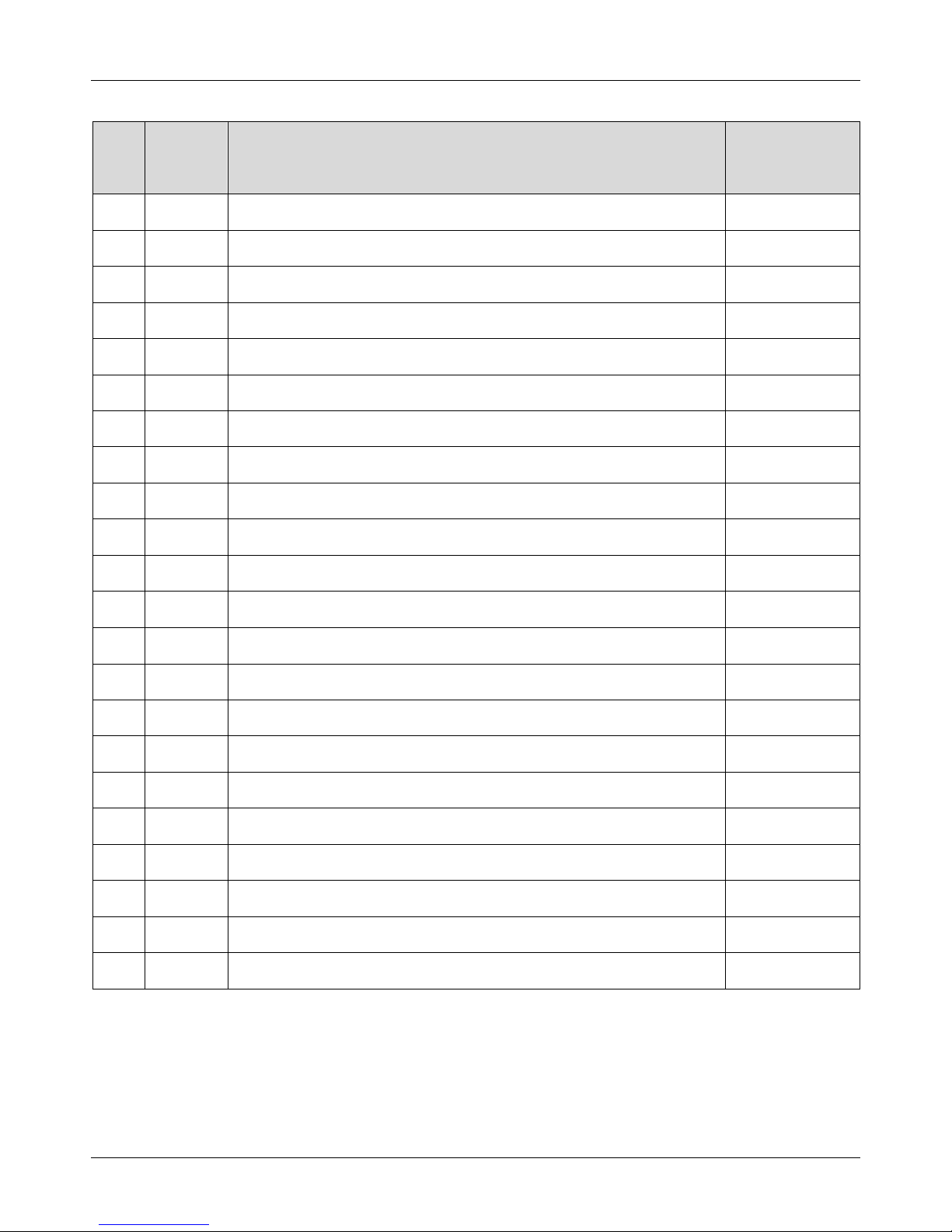

10. Pump Hardware Parts List 24V

MAN-059 8 FEB 2017

17

ITEM

PART NO.

DESCRIPTION

QTY/KIT

1

18-9015

ENCLOSURE BASE/RESERVOIR

1

2

18-9044

POWER UNIT 24V (PUMP + ADAPTER + MOTOR)

1

3

18-9025

MANIFOLD ASSEMBLY 24V

1

4

18-9027

LEVEL SENSOR

1

5

18-9028

ENCLOSURE GASKET

1

6

18-9028

ENCLOSURE LID

1

7

18-9024

FILL CAP

1

8

18-9029

POWER UNIT GASKET

1

9

18-9030

LEVEL WINDOW

1

10

18-9031

SCREW POWER UNIT

4

11

18-9032

WASHER SPRING POWER UNIT

4

12

18-9033

CABLE GLAND

1

13

18-9034

MANIFOLD BLOCK

1

14

18-9035

RELIEF VALVE

1

15

18-9036

SOLENOID VALVE

1

16

18-9022

COIL 24V

1

17

18-9037

ORIFICE 0.5mm

1

18

18-9017

PRESSURE SENSOR

1

19

18-9038

BULKHEAD FITTING

1

20

18-9039

ADAPTER FITTING MANIFOLD TO BULKHEAD

1

21

18-9040

SCREW MANIFOLD BLOCK

4

22

18-4033

MANIFOLD O-RING SEAL KIT

1

MAN-059 8 FEB 2017

18

11. Installation –Driveline Brake (Light - Medium Trucks)

1. The SIBS® driveline brake is installed on the forward side of rear differential carrier.

2. Drain and keep enough diff oil from the rear differential carrier to prevent spillage as the pinion bearing cage will be

removed for SIBS® brake installation.

3. Remove drive shaft from rear yoke. The drive shaft may be removed completely if desired.

4. Remove the yoke from the pinion shaft.

5. Remove the pinion bearing cage and retain any shims for later use. Ensure no dirt ingress into the diff centre.

6. Remove and keep the bearing rollers. Remove and discard pinion seal.

7. The pinion bearing cage must be machined as per ABT drawing to suit the attachment of the SIBS® brake.

8. Attach the modified pinion bearing cage to the diff centre as per Canter manual. Ensure all shims are reused. Do not

attach any mounting bolts at this stage.

9. Attach the outer bearing roller and pull the pinion shaft forward to ensure it is positioned correctly.

10. Attach the pinion seal to the bearing cage.

11. Apply Loctite 515 between the bearing cage and the SIBS® inner brake housing. Note: in some cases a mounting adapter

is required between the bearing cage and the inner housing. If required apply Loctite 515 to both sides.

12. Attach the inner housing with the brake pads positioned to the top of the brake.

13. Attach the mounting bolts and washers. Torque to 100Nm. Repeat 3 times over 5 minutes.

14. Ensure the housing o-ring is attached to the outer brake housing.

15. Ensure the brake pads are in position on the inner brake housing.

Figure 1: Diff centre with inner housing attached.

16. Attach the V-seal to the yoke.

17. The preassembled outer housing should be attached to the yoke and rotor. Ensure brake pads are attached to the outer

housing.

Brake Pads

Mounting Bolts and washers

Pinion

Seal

MAN-059 8 FEB 2017

19

Figure 2: Outer housing, yoke and rotor assembly.

18. Attach the outer housing, yoke and rotor to the inner brake housing. Use of a jack or lifting table is recommended to

assist with lifting the assembly into position.

19. Hold the brake rotor to prevent it from detaching from the yoke during assembly.

20. Lift outer assembly and align the yoke with the pinion shaft with the EMMA spring covers positioned towards the bottom

of the brake.

21. Once the brake is held by the pinion shaft, rotate the outer housing until the EMMA spring covers are positioned towards

the top of the brake.

22. Remove any rotor retaining devices once the inner and outer housings are as close to each other as possible.

23. Align the dowel pins before attaching the housing bolts.

24. Fit the 12x M10 bolts and torque to 50Nm in sequence. Ensure each bolt is torqued twice.

25. Attach the 2x grease nipples to the yoke.

26. Attach the pinion shaft nut. Set preload and torque as per Fuso Canter Manual.

27. Ensure the diff rotates freely when the SIBS® brake is released.

Figure 3: Brake mounted in position on the forward side of the rear diff centre.

28. Assemble the drive shaft onto the ABT yoke. Torque fasteners to 130Nm.

29. Complete the hydraulic and electrical installations as per sections 10 and 11 of this manual.

30. Remove the 4 x retractor bolts from the brake and retain in the vehicle.

Ensure Brake Pads are in position

before attaching rotor (not shown)

EMMA Spring cover

EMMA Spring cover centred

at the top of the brake

M10 Housing bolts located

on the rear facing side

MAN-059 8 FEB 2017

20

31. Attach 3 x taper plugs to the spring covers. Use Loctite Silver Grade Anti-seize on the threads of the taper plugs to assist

with future removal. Torque to 10Nm.

32. Silicone may be used to fill the socket head of the taper plugs to prevent dirt ingress.

33. Attach 1 x pad wear indicator plunger to the EMMA piston inside the remaining hole in the spring cover. Torque to 15Nm.

34. Attach the pad wear indicator plug to the spring cover over the pad wear indicator plunger. Ensure it is threaded all the

way onto the spring cover. Torque to 15Nm.

35. Attach the fibre washer and cap. Torque to 10Nm.

Figure 4: SIBS Brake assembly attached to rear diff centre.

36. Mount the expansion chambers as high as possible in a protected location on the vehicle. ABT recommends mounting to

the chassis cross-member.

37. Secure using the supplied mounting hardware.

38. Run a length of breather hose between the expansion chamber and the brake unit.

39. Route the hose away from the exhaust and any moving components. Allow extra length for axle articulation.

40. Protect areas of the hose that may abrade using spiral guard.

41. Ensure SIBS® fluid can easily drain back into the brake units.

42. Secure the hose using supplied P-clips.

Figure 5: SIBS Brake assembly attached to rear diff centre.

Pad wear indicator location

Expansion Chamber

Breather hose fitting

On brake unit

Table of contents