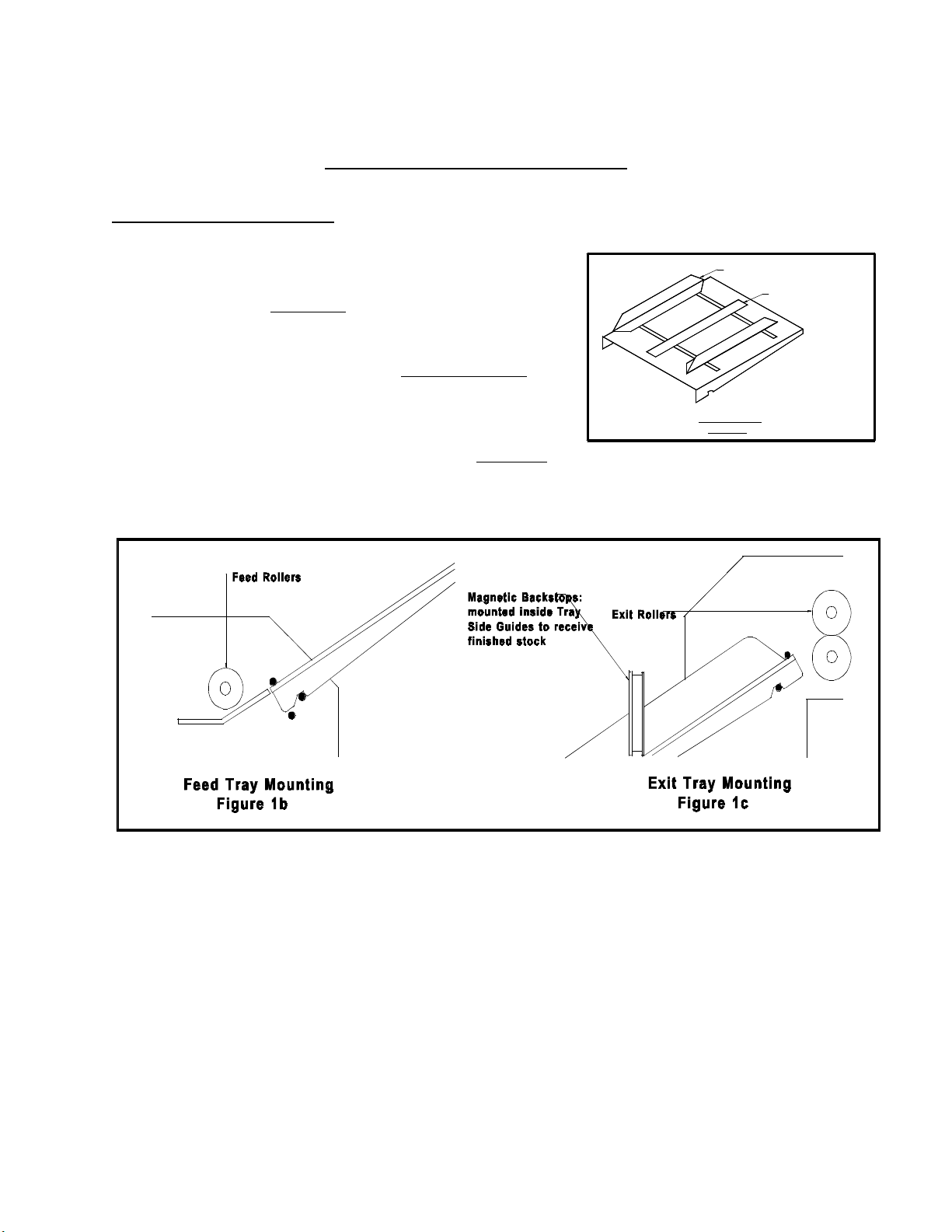

position of the magnets depends on the stock being processed, but the magnets should be set such that

the stock does not slide down the exit tray too far, possibly causing sheets to get in uncollated order.

2.2 Numbering Heads

The numbering heads are already secured

to the drive unit by two screws through

the numbering head mount block as

shown in Figure 2. The drive unit is then

mounted to the drive unit mount block

using the hand knob provided. While

installing the drive unit, make sure the

screw cap on the back of the drive unit

fits in the cavity on the drive unit mount

block so that the rubber plug provides

some pressure against the screw cap. You

may have to back out the left/right pitch

screw in order to do this. Plug in the cord

from the drive unitinto the appropriate

receptacle on the non-operator side cover

(closest head to the closest receptacle). If

your machine is equipped with more than

one head, by convention, the numbering

head and drive will refer to unit closest to

the operator control panel as head #1(H1)

and the other will be head #2 (H2).

The height of the numbering head has been factory set and it is critical to the proper performance

of the drive unit and numbering head. This distance is approximately 3" or the thickness of a numbering

wheel change stylus. However, the numbering head must be levelled to ensure that the numbering

wheels strikes the sheet square to provide a quality inked impression and a flat crash impression on

carbonless sets. This will be discussed later (Section 4.11).

The numbering heads can operate through 360Ε. This is done by loosening the numbering head

rotation screw (using the large hexdriver supplied) located on the front of the numbering head mount

block. Once the screw is loose, the head is free to rotate. Tighten the screw once the desired position is

achieved in order to prevent any movement during machine operation.

The standard numbering head is

3

/

16

" (4.5mm) Gothic style, reverse order, 6 digits with 2 drop wheels.

The numbering head employs a pre-inked pad, which can be purchased in red or black. These ink pads

will supply you with approximately 15,000 impressions. Uninked pads may be purchased if a different

colour is required (Note: any ink used must be a non-metal corrosive one, labelled numbering machine

ink).

The numbering head comes standard with six numbering wheels (a seventh numbering wheel is

optional), the last two of which are drop wheels (this will be discussed later). The first 5 digits may be

activated automatically. The 6th (or 7th) digit must be changed manually. Also available are letter

prefix wheels (A-J; K-R; S-Z) and a µprefix wheel. Modifications are possible with new numbering

head orders or by special order.

Change Stylus: Numbering

Head should be approx. 1/4"

from the platen, or the

thickness of a change stylus

Figure 2: Numbering Heads

Numbering Head

Mount Block

Numbering Head

Rotation Lock Screw

Numbering Head

Platen

Drive Unit

Drive Unit Mount Shaft

Anti-Pitch Block

Hand Knob

(Forward/Back Pitch)

Drive Unit Mount Block

Left/Right Pitch Screw

Forward/Back

Pitch Screw

Hand Knob

(Left/Right Pitch)

8