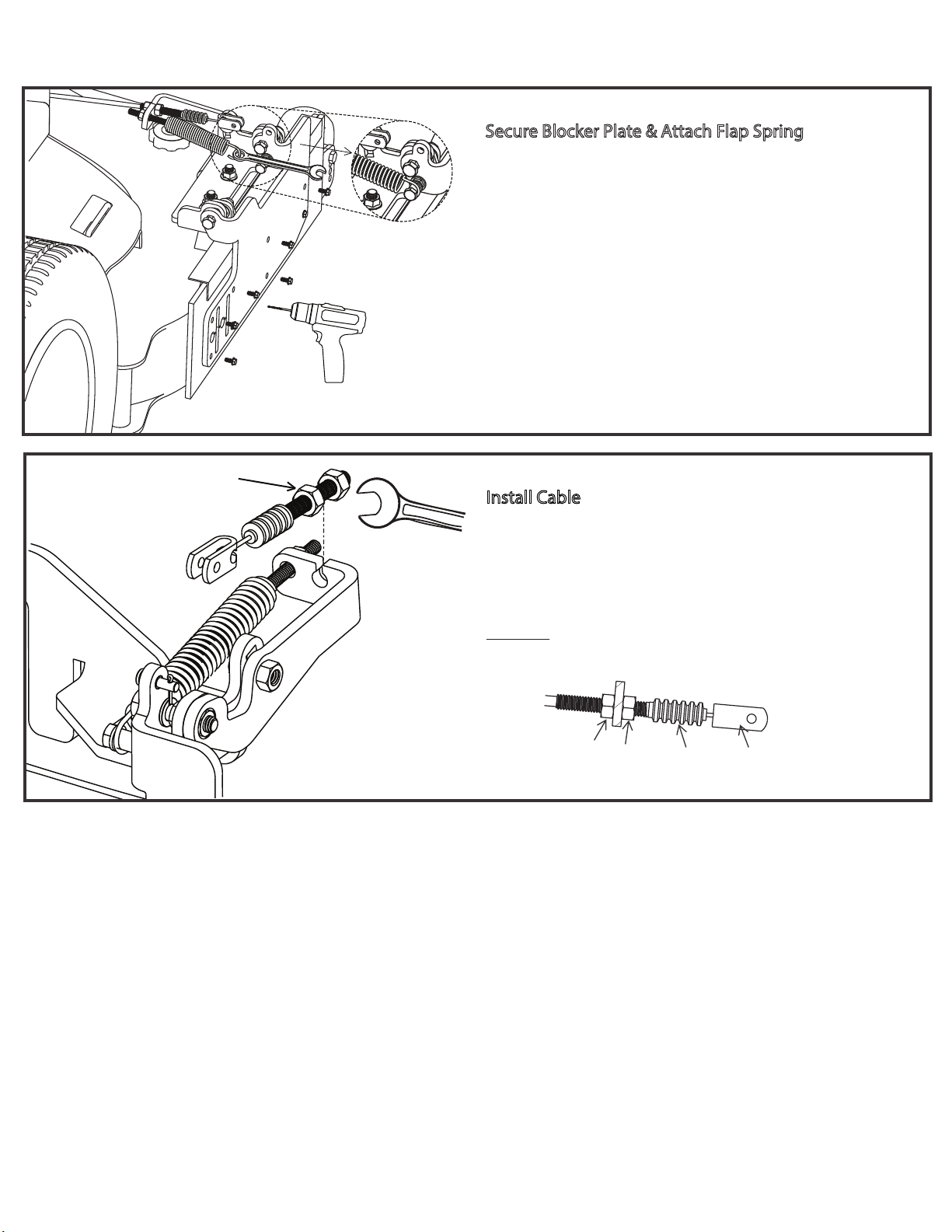

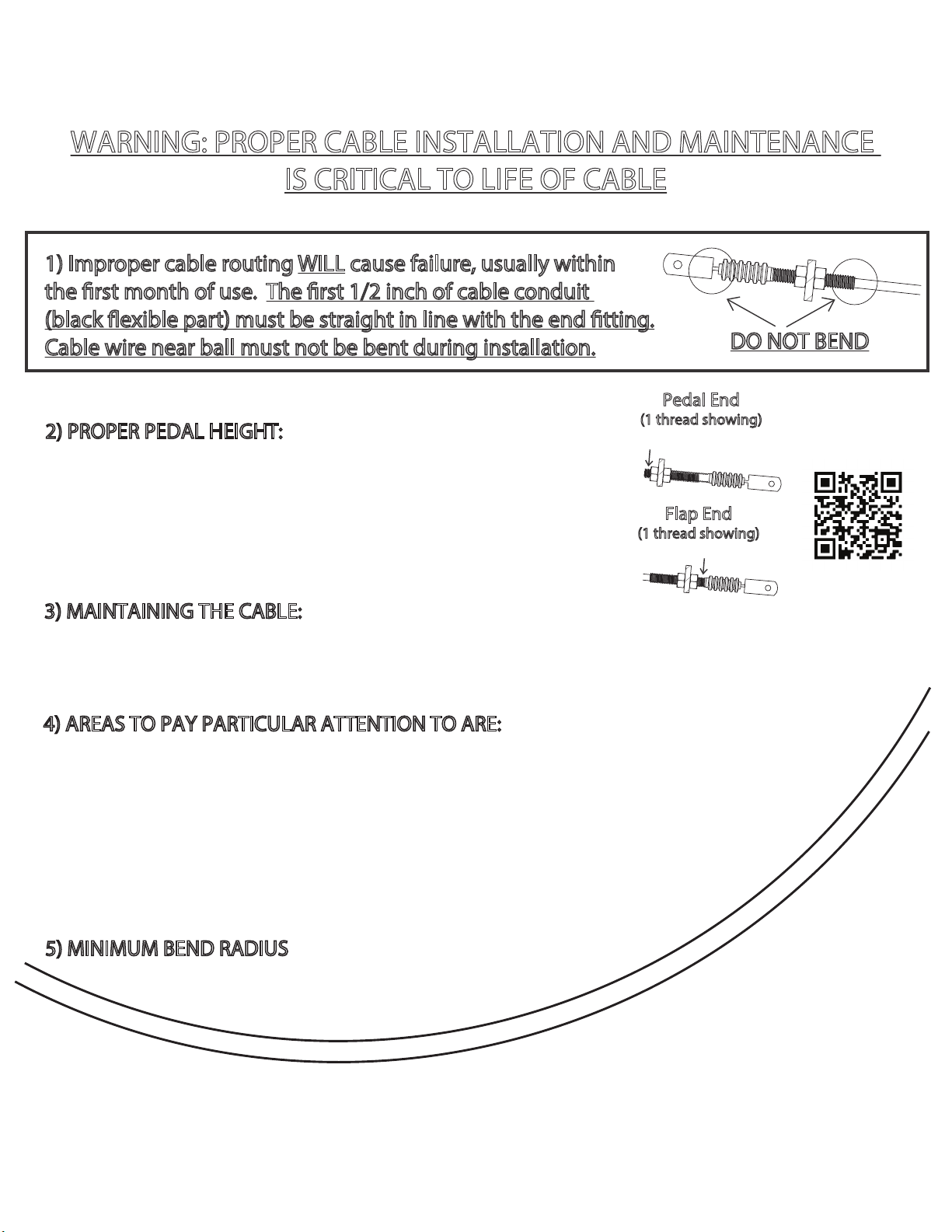

PEDAL END

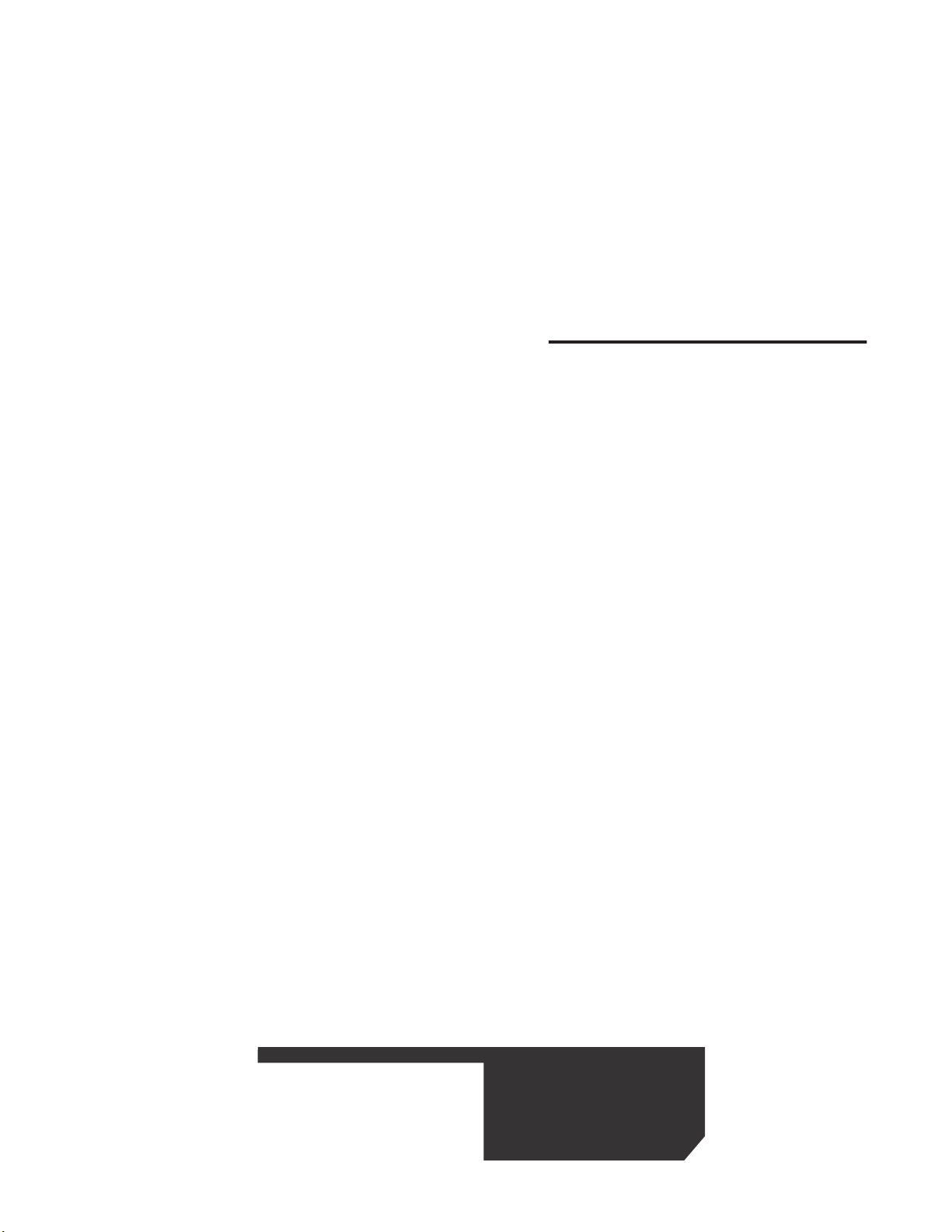

(Cable Installaon, step 1 and 4, AREAS TO

PAY PARTICULAR ATTENTION TO, Recommended cable roung, WARNINGS)

(Recommended cable roung, SECURE

WITH CABLE CLAMP/ZIP TIE)

Cable Installaon, step 2,

PROPER PEDAL HEIGHT)

(Cable Installaon, step 3, MAINTAINING THE CABLE)

FLAP END

(Cable Installaon, step 1 and 4, AREAS TO

PAY PARTICULAR ATTENTION TO, page 6 installaon guide, WARNING)

ROUTING

(Cable Installaon, step 4, AREAS TO PAY PARTICULAR

ATTENTION TO)

(Cable Installaon, step 5, REFERENCE 6” RADIUS)

(See recommended cable roung)

GrassFlap.com Phone: (502)594-3546 6