PHASE I

BREADBOARD

tn this phase,you will have an opportunity to construct an experimental

breadboard similar to that used by engineers and technicians in industry.

A breadboard is a layout of electronic parts, wired in such a way that

the parts may be easily added or removed during experimental work.

DISCUSSION

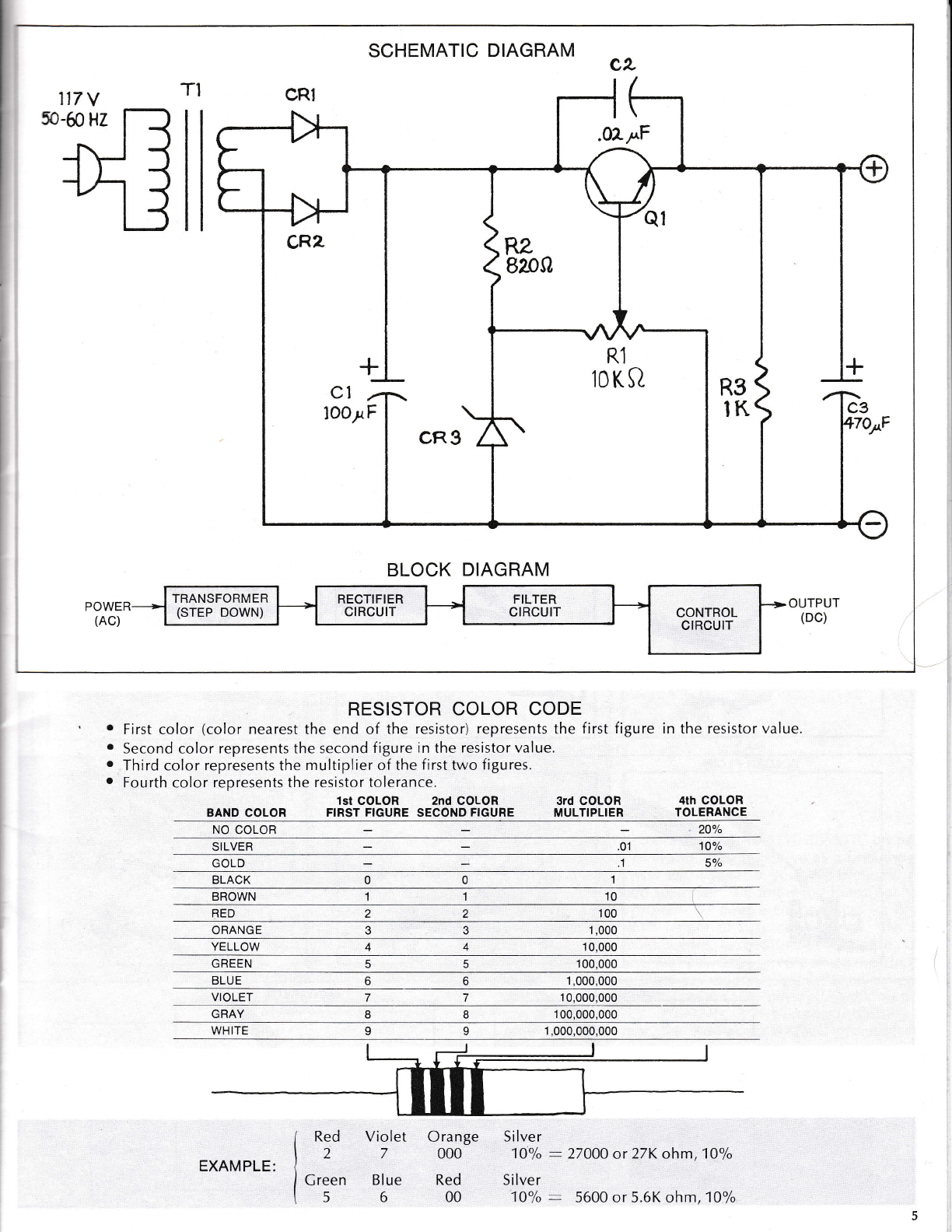

Your Model 803 solid-state Power Supply consists of four

stages of circuitry: power transformer circuit, rectifier circuit,

filter circuit, and voltage control circuit. ln this phase you

will study the operation of your power supply by bread-

boarding one stage at a time.

TRANSFORMER EXPERIENCE

DISCUSSION

A transformer is an alternating current (AC) device that

transfers electrical energy from one circuit to another. lt is

usually used to STEP UP or to STEP DOWN an AC voltage.

ln its basic form, the transformer consists of two coils of

wire wound around an iron core. One coil is connected to

the AC source voltage and is called the PRIMARY winding;

the other coil is called the SECONDARY winding and pro-

vides the proper supply voltage.

The transformer used in this power supply is a step-down

transformer with a center-tap on the secondary winding,

as illustrated by the schematic symbol shown in Fig. A.

The application of two important laws in electricity make

transformers possible. They are: (1) An electric current flow-

MAGNETIC FIELD

ing through a coil produces a magnetic field that varies w'ith

the current; and (2) A magnetic field cutting across the wires

in a coil induces a voltage in the coil. Transformer action is

illustrated in Fig. B. It shows that the changing magnetic

field, created by the varying current in the primary winding,

induces a voltage in the secondary winding as the magnetic

field cuts across the turns of wire in this coil.

The relationship between the input voltage (primary) and

the output voltage (secondary) is determined by the number

of turns of wire in the primary and the number of turns of

wire in the secondary. This relationship is called the TURNS-

RATIO and is expressed mathematically as,

Eprimary _ N primary

Esecondary " N secondary

where,

E is voltage and N the number of turns.

For example: a transformer has 1,000 turns in the primary

and 500 turns in the secondary. lf a voltage of 1-10 volts AC

is applied to the primary, the secondary voltage will be 55

volts AC.

That is, 110 '1000

tsecondary 500

Esecondary : -ry

1000

Esecondary : 55 V

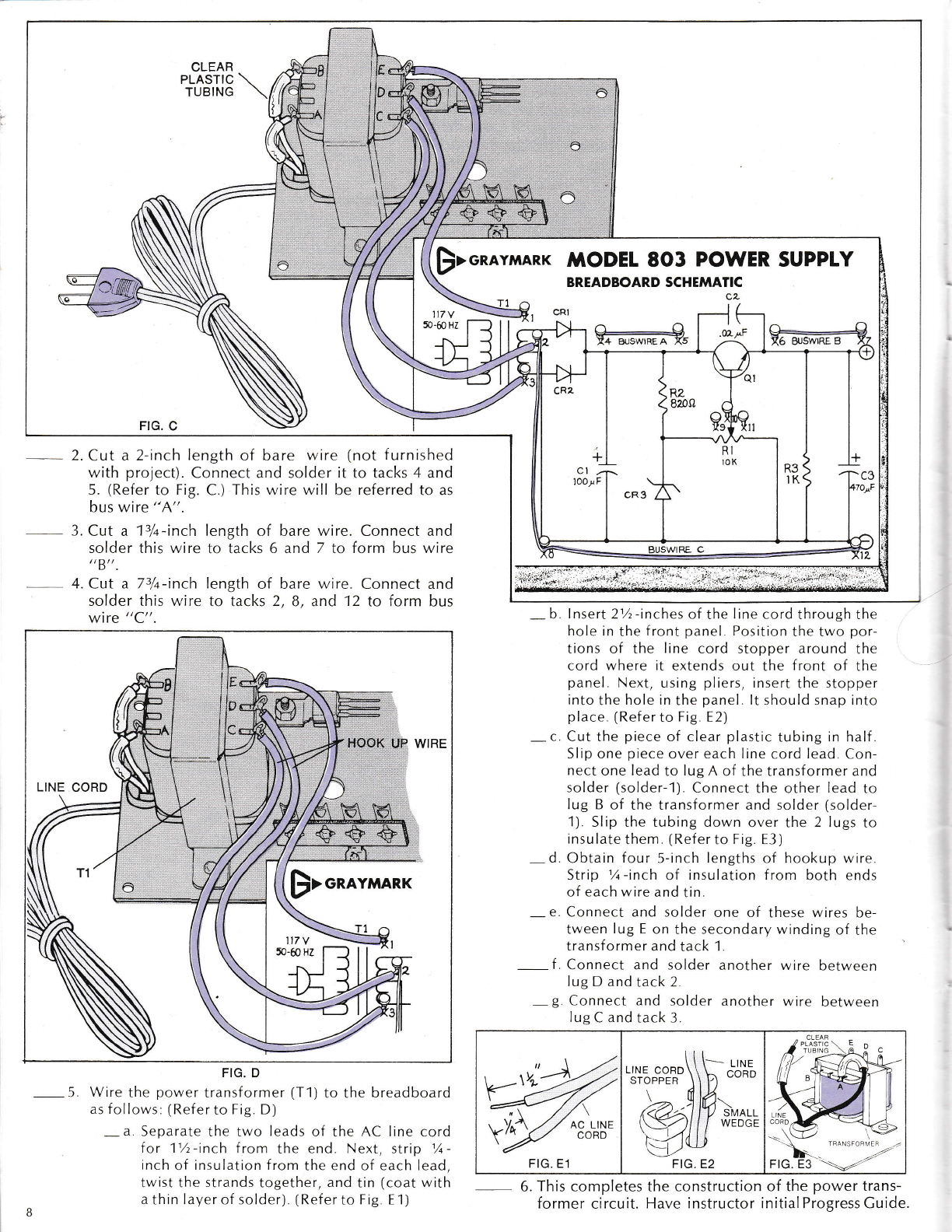

CONSTRUCTION

Cut out and fasten the BREADBOARD SCHEMATIC on page

23 to a flat piece of wood. This will serve as a breadboard

base upon which you will construct your experimental cir-

cuits. You will need to obtain the following items not fur-

nished with your project: (1) Twelve copper tacks (or brass

brads); (2) A 12-inch length of bare copper wire; and (3)

Four pieces of hookup wire, each 5-inches in length. 'DO

NOT CUT THE LEADS of any components unless instructed

to do so, because these components will be used for con-

structing other circuits. Caution: Do not disturb the mount-

ing of transistor Q1 . However, if it becomes necessary to

remove it, be sure the insulating washers are replaced

properly.

-- 1. Insert a tack into the breadboard at X marks 1

through 12 on the schematic.

FIG. ,ll,tlll|llll,ll,lllllll,l,]ll|l|lill,t,:l|llIl|lllllll|

CENTER-TAP

PRIMARY

WINDING

SECONDARY

WINDING

STEP-DOWN

FIG. A