Before application, customer must read this instruction manual carefully. If any doubt, please

contact our company directly (1-866-493-0524). We are free from any accident due to improper

operation.

1. Application

The sprayer has the advantages of high efficiency, uniform droplet, long spray range, support-

ing with high-performance motor, stable performance, reliable and durable. It is specially

applied for large area spraying operation of greenhouse. It can also be used for Public

sanitation and disinfection, such as airports, docks, hotels, restaurants, hospitals, public

transport, theaters, communities, entertainment. As well as food processing, pharmaceutical

companies, animal husbandry industry’s Disinfection and sterilization, Health and epidemic

prevention.

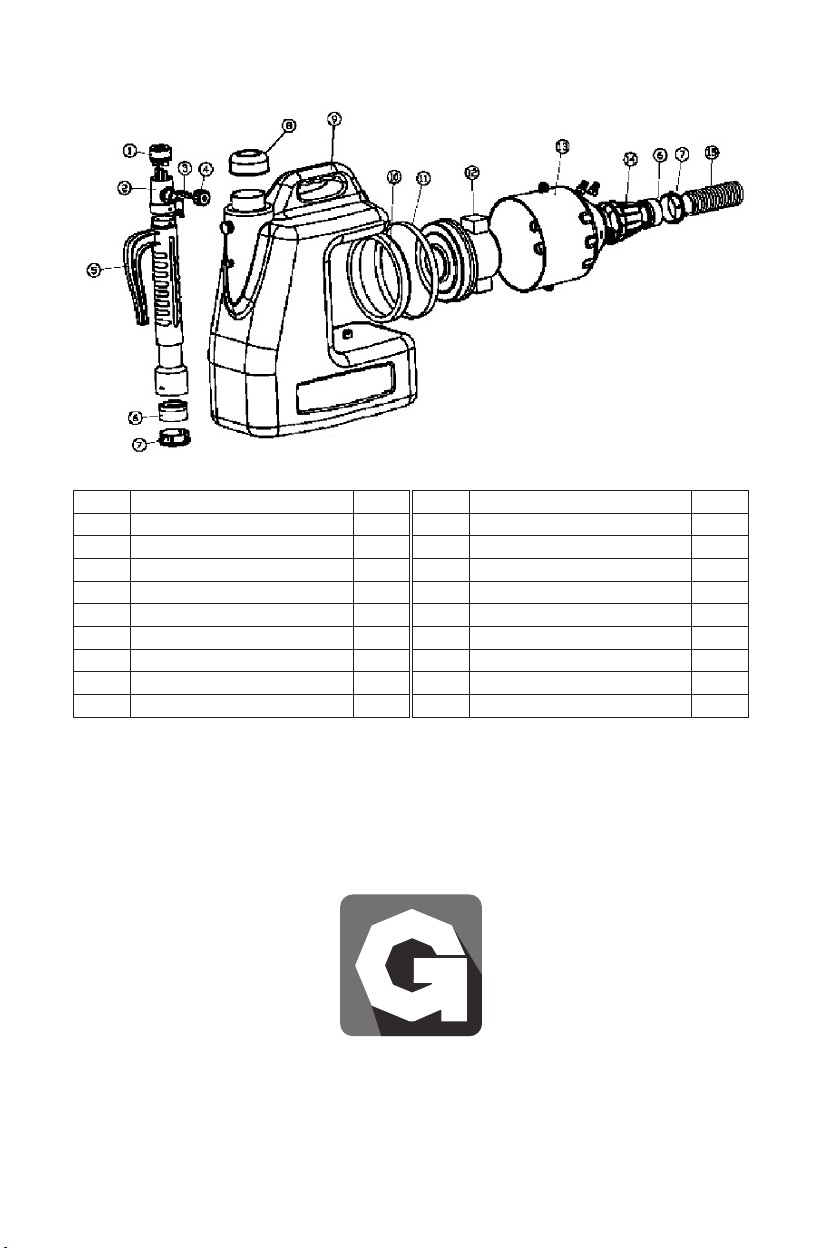

2. Structure of product: Illustration shows brief structure.

3. Warning

3.1 NO direct spraying highly toxic pesticides, undiluted pesticides, banned pesticides and

special chemicals. It should comply with the safety instructions provided by the pesticide

manufacturers when treating of pesticides.

3.2 On security grounds, the chemical tank cannot be added into inflammable and explosive,

highly volatile special chemicals, such as gasoline, alcohol, phenylacetone etc. Cannot add

highly corrosive liquid, such as caustic soda solution, hydrochloric acid etc. In case of injury

or fire and other major security incidents. (Warning: Keep the machine dry, wet hands are

prohibited to operate the power switch, to avoid electric shock.)

3.3 The machine can only be operated by a person who is familiar with the performance and

operation method of the machine, and has the knowledge of relevant safety operation, the

following personnel operation is PROHIBITED strictly.

3.3.1 Children or the elderly.

3.3.2 Mental illness or sick deformed and weak people.

3.3.3 Drinking people.

3.4 Do not use insoluble powder with this sprayer. The solid matter is easy to block the screen

and hose to pump. Do not operate with strong acids, strong based or flammable liquids. Do

not use high-resistant and very toxic pesticides for pest controlling purposes on vegetables,

fruit trees and plants. Don’t spraying towards others face.

3.5 Do not operate sprayer in temperatures exceeding 113°F(45°C) or lower than 14°F(-10°C)

3.6 Trial spraying with clean water is necessary for initial use to make sure no light leakage or

poor atomization occurs.

3.7 It is strictly prohibited to keep this sprayer near fire or expose the base to water or immerse

the sprayer in the water to clean or to fill it with water.

3.8 Wear a mask and gloves to protect skin and to avoid direct contact with pesticides or

harmful liquids. Do not spray pesticides against the wind of spray towards humans, animals

or food. Do not operate for extended periods of time under high temperatures.

3.9 After spraying, please make use to treat the waste according to the manual provide by the

pesticide manufacture to protect the environment.

4. Operation

4.1 Put the sprayer on the horizontal table, tighten the pipe connector (14) on the motor cover

(13) clockwise.

4.2 Adjust the motor switch and the adjusting nut (4) in OFF position.

4.3 Plug in and turn on the power switch to check the motor is running or not.

4.4 Add the chemical after filtered with the filter funnel, tighten the tank lid screw.

4.5 Turn on the power switch (ON), adjust the spray volume appropriately.

4.6 Then start to spray.

1