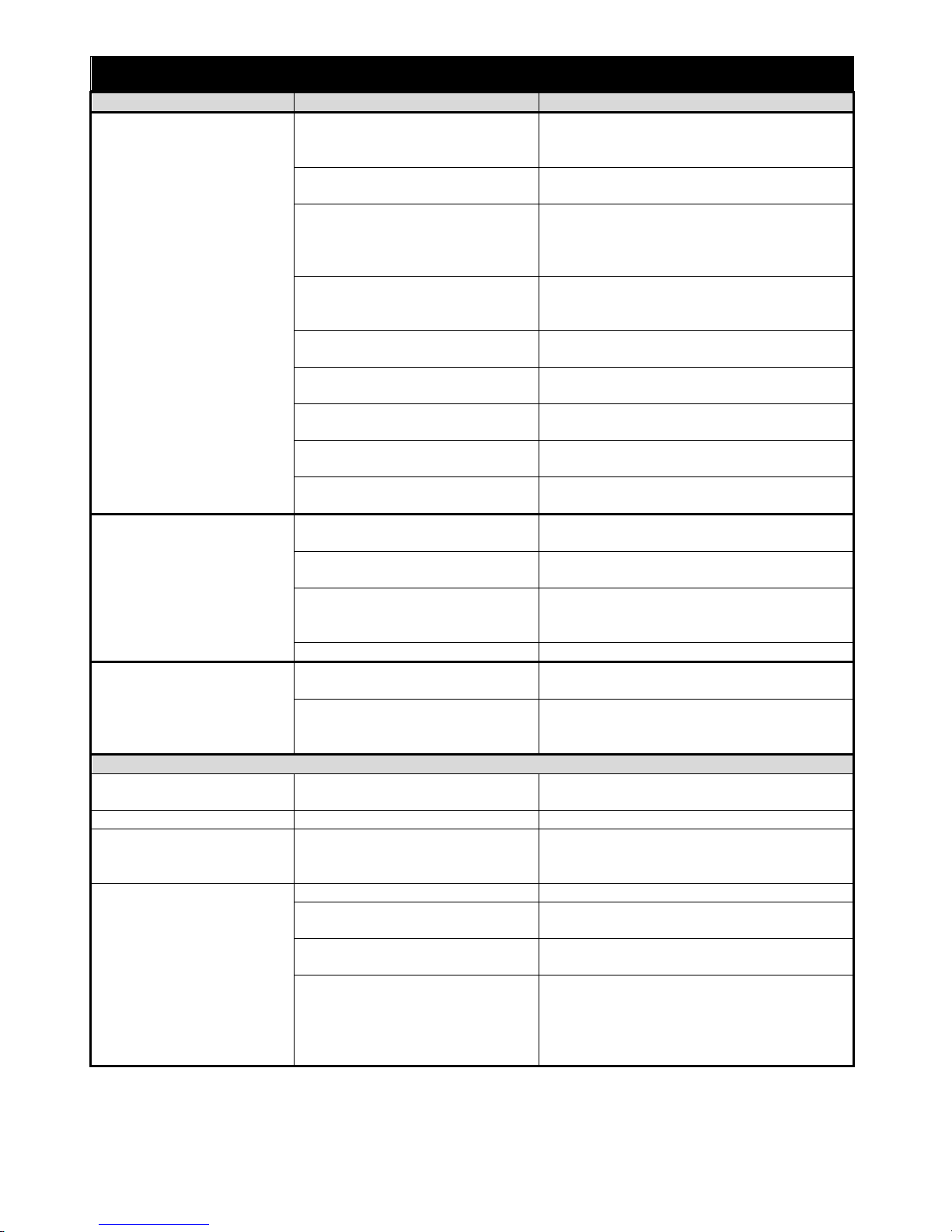

Any standard EDR Series Refrigerated Air Dryer manufactured by Great Lakes Air Products is

warranted free from defects in material and workmanship under normal use for a period of 2-Years.

The warranty applies to original purchaser effective at date of shipment from manufacturer’s

warehouse. Said warranty consists of 1-Year job site labor and 2-Years covering OEM replacement

parts. The company’s obligation under this warranty is limited to repairing or, at its sole option,

replacing, during normal working hours at an authorized service facility of the company, any part

which in its judgment proved to be not was warranted within the applicable warranty period.

This warranty covers the standard catalog EDR series air dryers including options, excluding

customer maintained components such as separator float assembly, drain solenoid, drain

strainer screen, fan motor lubrication, condenser cleaning, and filter element replacement.

This warranty applies to equipment installed, operated and maintained in accordance with the

procedures and recommendations as outlined in the owner’s manual by Great Lakes Air Products.

Great Lakes Air Products will not be responsible for the following items: Freon, insulation, torch

charge, reclaiming charge, truck charges, freight damages, or any parts not original to the EDR

series dryer.

In all cases, seller must be given a reasonable opportunity to investigate and inspect any assumed

defects. At seller’s option, buyer must return any defective materials to seller’s plant or authorized

depot at buyer’s expense. Freight charges for returned or replacement machines or parts are not

the responsibility of Great Lakes Air Products. Seller’s liability whether on warranty contract or

otherwise shall be limited to repair or replacement of material found within such period to be

defective. In no event shall the seller be liable for consequential or special damages.

Great Lakes Air Products shall not be responsible for any incidental or consequential damages or

other costs resulting from the following; labor charges, delays, vandalism, negligence, fouling

caused by foreign material, damage from adverse air conditions, chemicals, or any circumstances

over which Great Lakes Air Products has no control.

The liability of Great Lakes Air Products for all loss or damage resulting from non-conforming goods

or tender, including breach of any and all warranties, shall be limited to refund of the purchase price

of the particular goods with respect to which the loss or damage occurred.

This warranty is in lieu of all other warranties oral or written, expressed or implied, including

warranties of merchantability or fitness for a specific purpose are hereby excluded and disclaimed.

This warranty shall not apply to any equipment, which has been subjected to misuse,

shipping damage, nonpayment, neglect or accident, nor shall it apply to any equipment that

has been repaired or altered by persons not authorized for each incident with a Great Lakes

Air Products Authorization number.