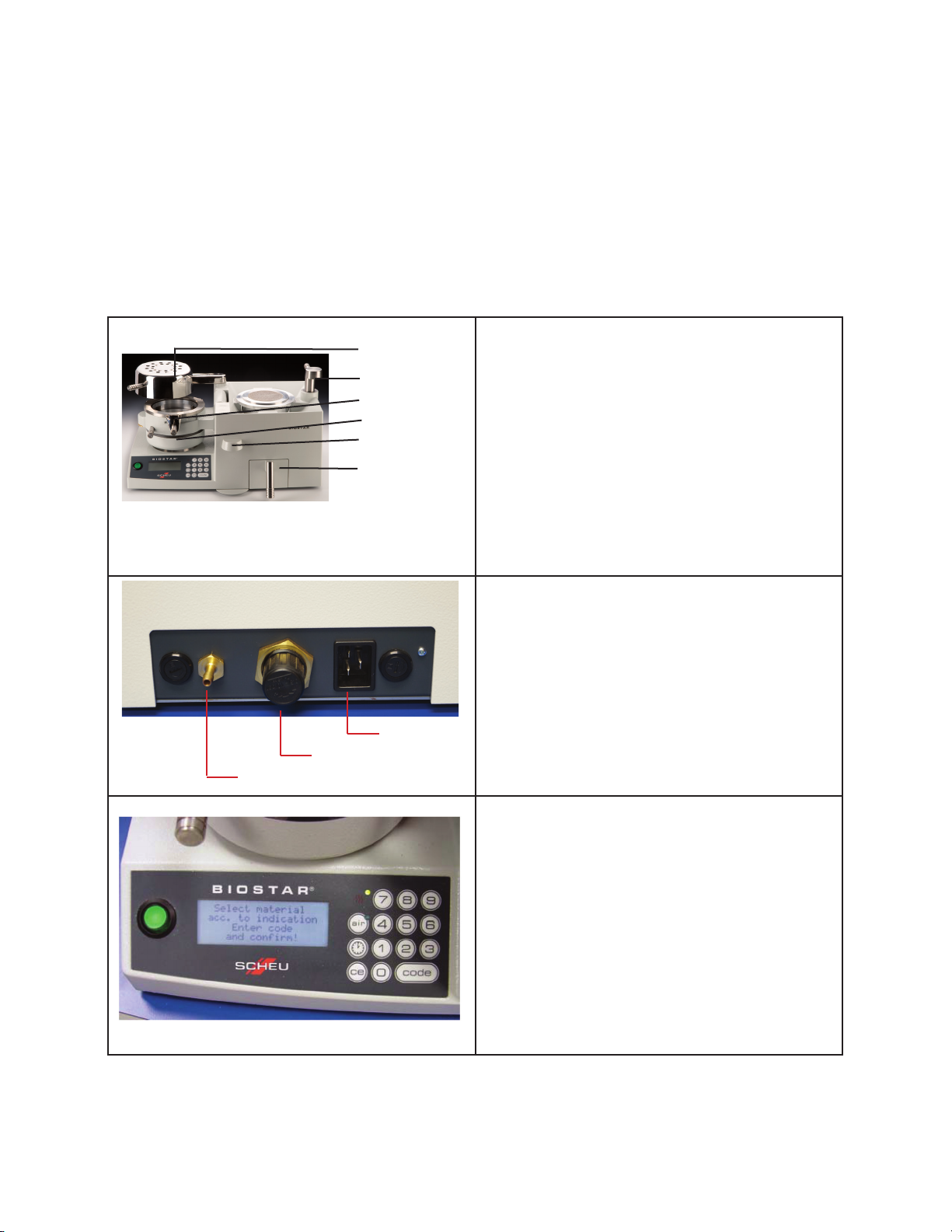

Heating Element: Found on left side of

machine, swivels from front to back and is used

to soften thermal-plastics.

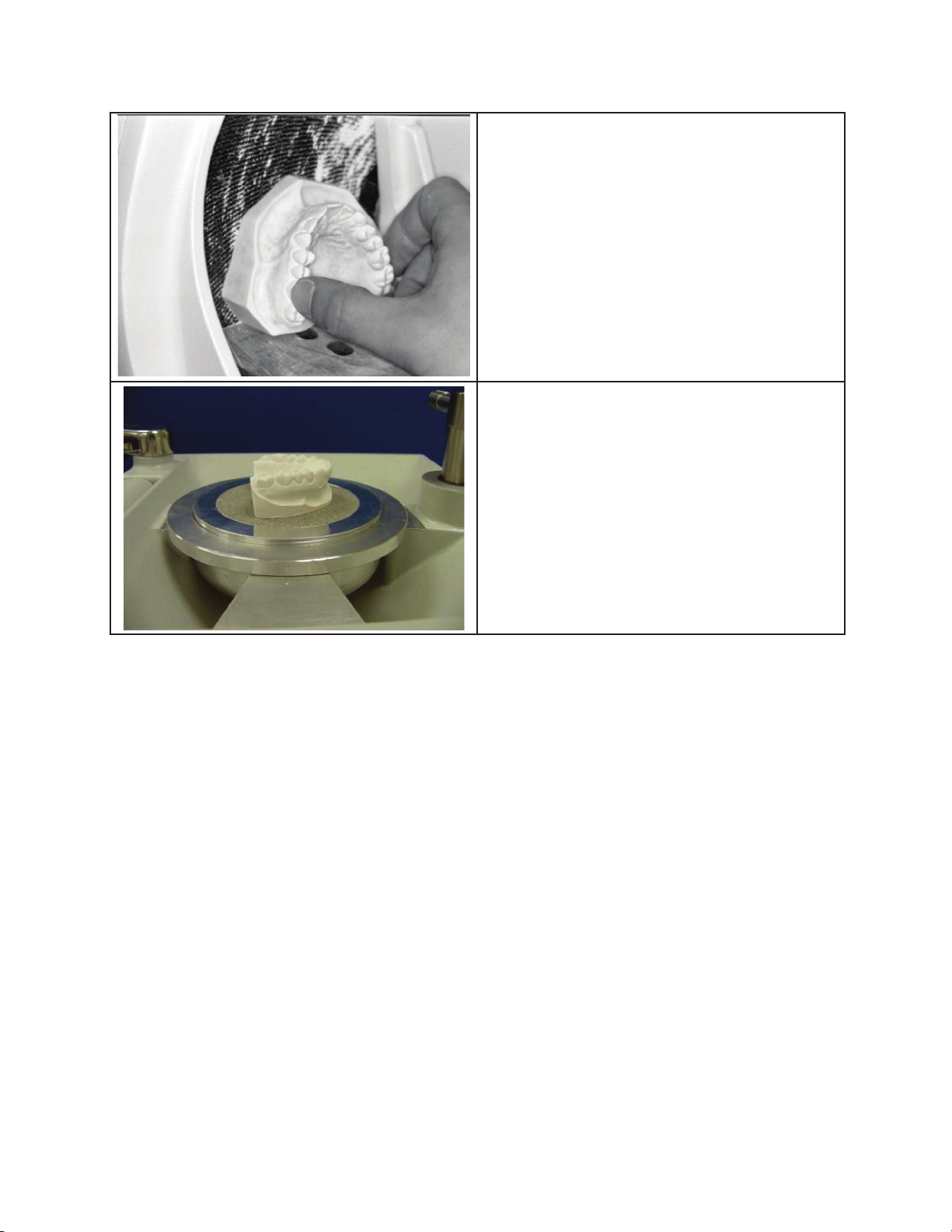

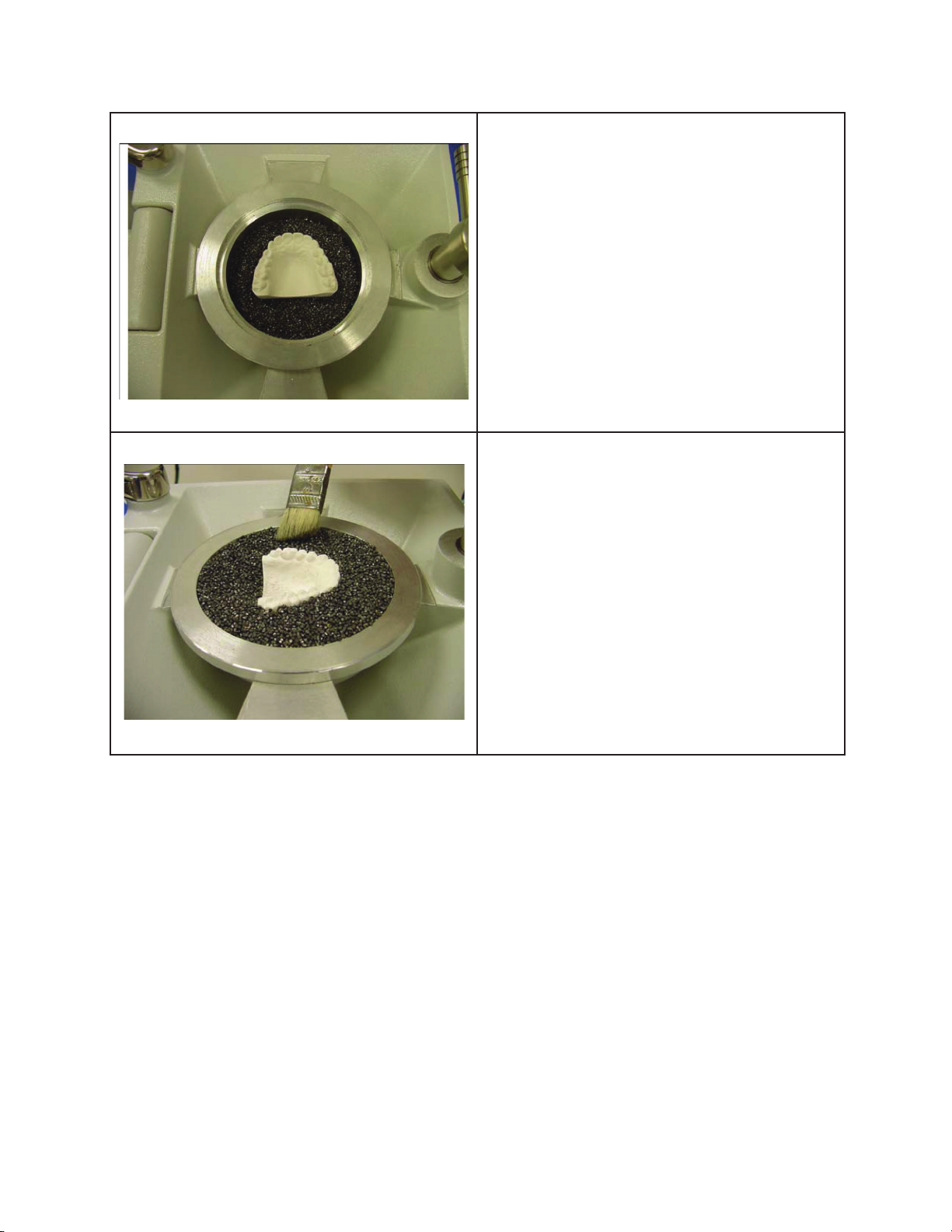

Pressure Chamber: Compartment that the

thermal-plastic material is held, heated, and

formed over a dental model.

Locking Handle: Holds chamber in molding

position and allows air pressure to enter

chamber.

Clamping Frame: Secures thermal-plastic to

chamber.

Pellet Drawer: Contains overow of pellets.

Bar Code Scanner: Automatically enters the correct

processing information for the thermal-plastic.

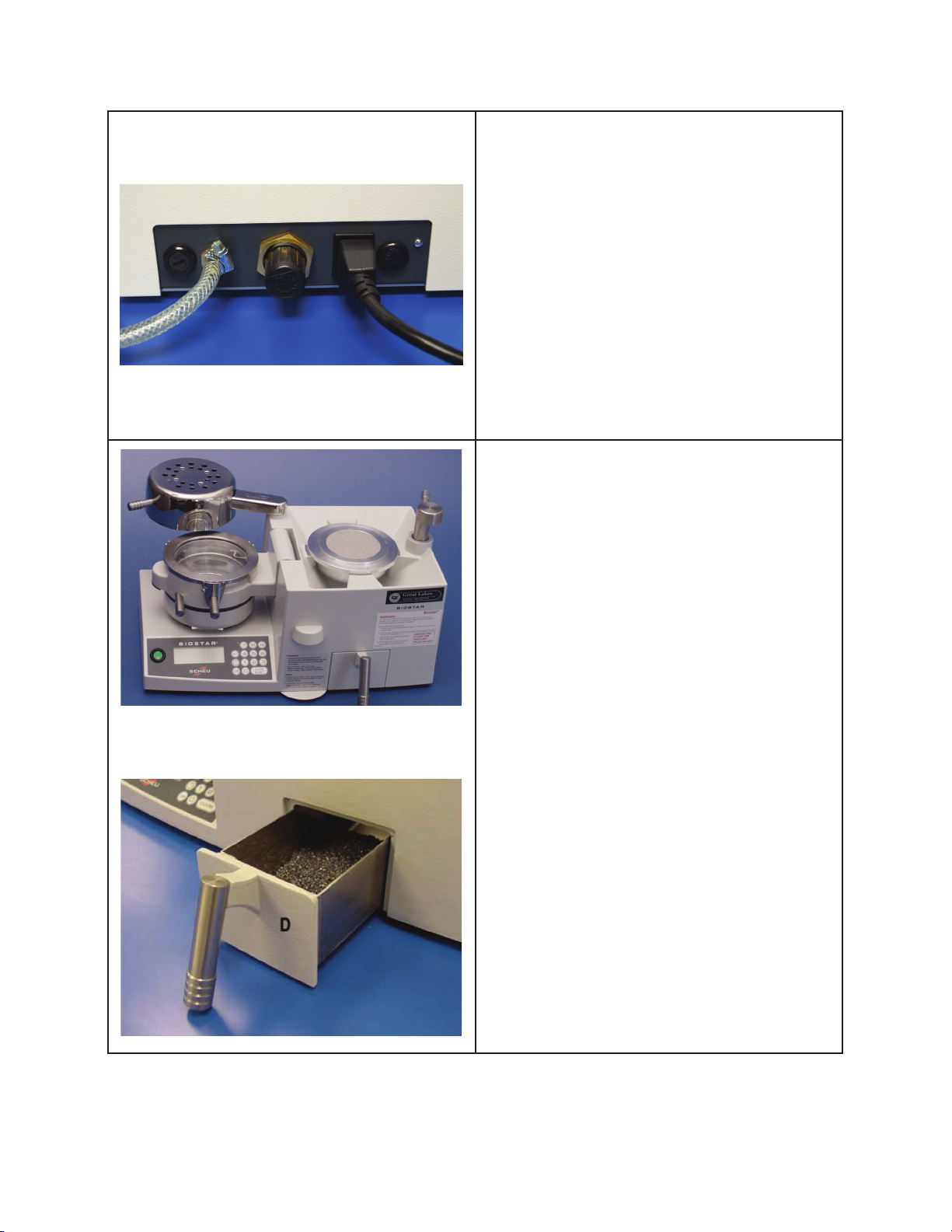

Plug with Fuse: Built-in plug with a two 8-amp

fuse compartment.

Pressure Controller: Air pressure adjustment

dial to control the amount of pressure that is

used within the Biostar.

Compressed-air Connection: Connects to

laboratory air pressure source.

On/Off Switch: Power switch.

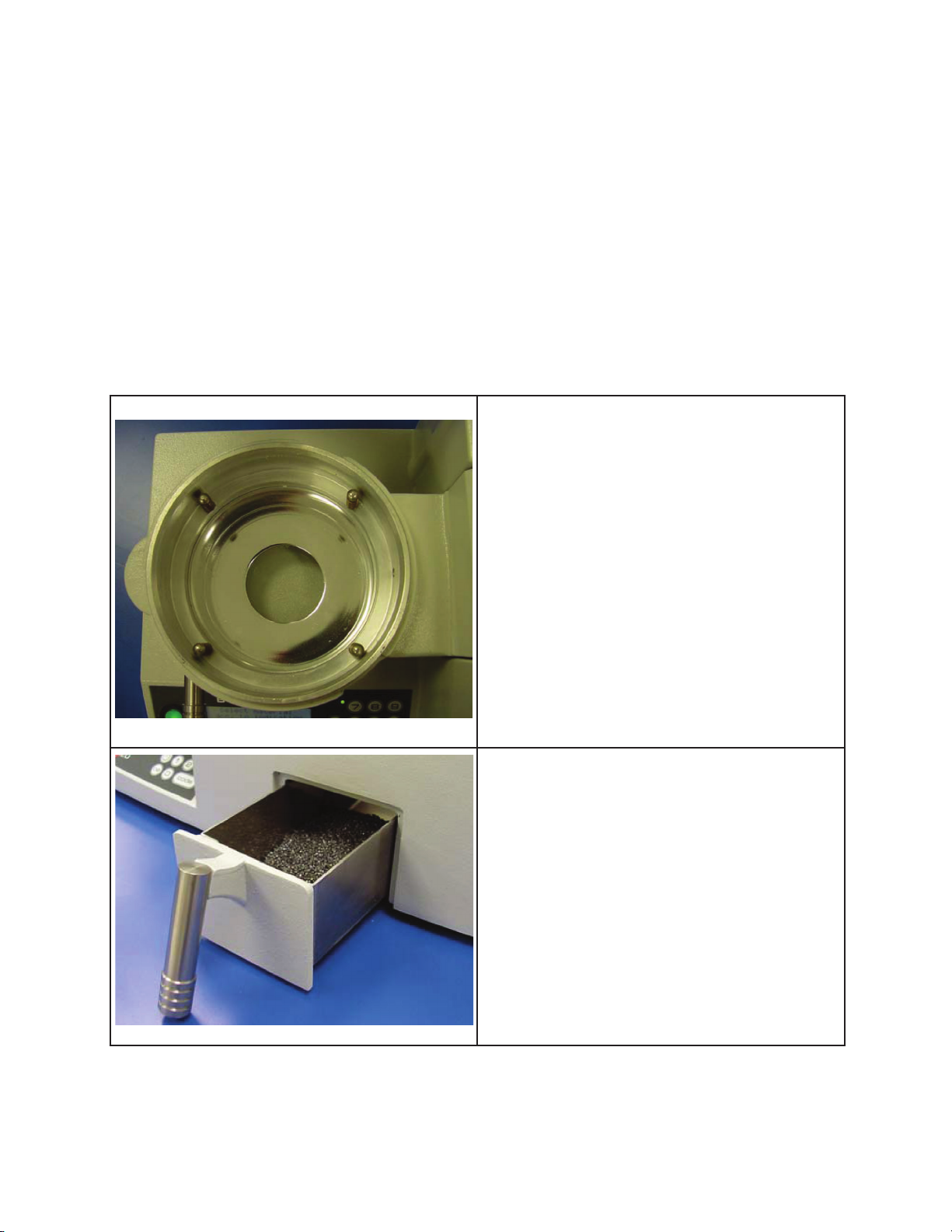

Code Button: Programs heating and cooling

operating times for material heating and

pressure forming.

Air Button: Removes air pressure from

chamber.

CE Button: Erases information placed in

memory.

Time Button: (Illustration of clock) Allows

operator to manually program heating and

pressure molding times, separately.

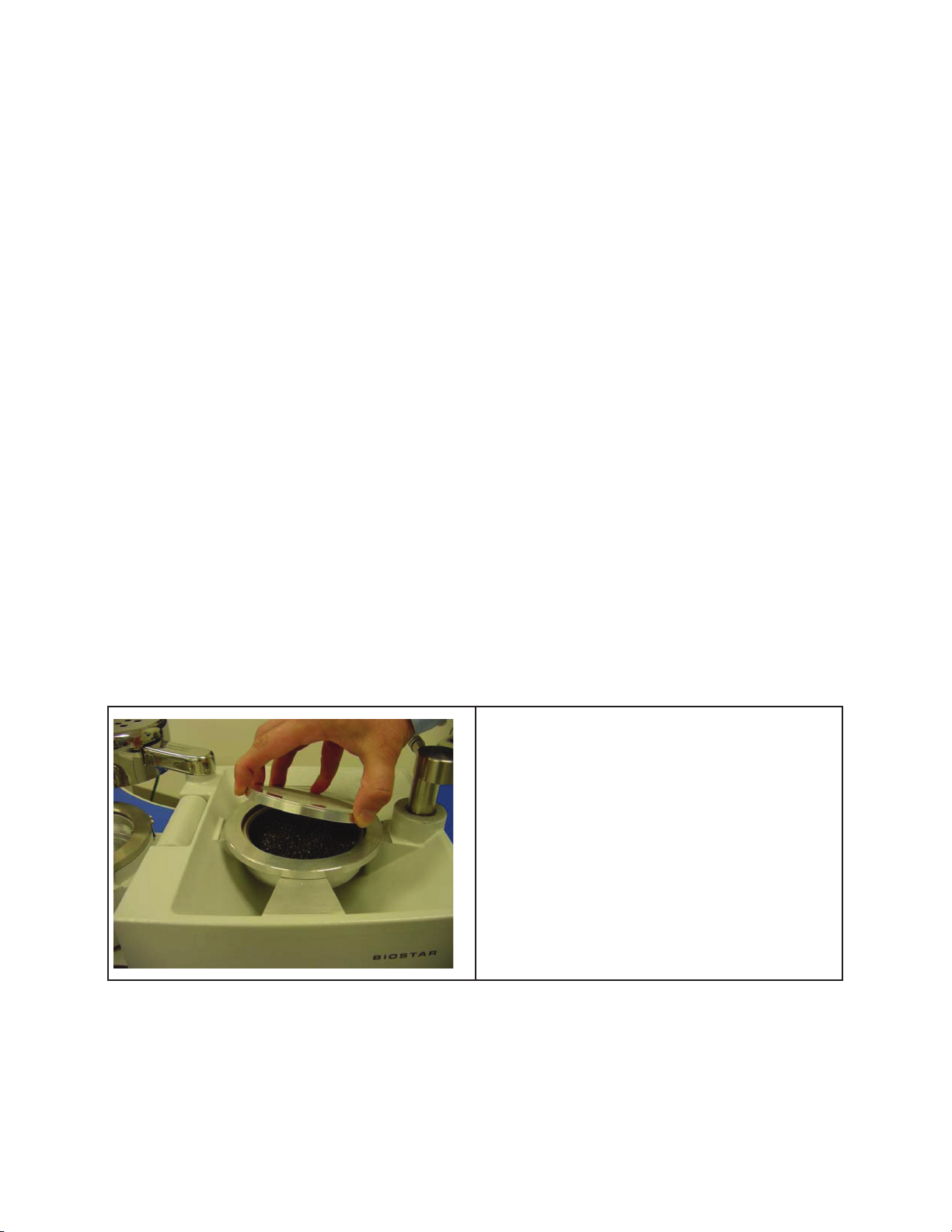

After inspecting the items, remove all packing material, and position the Biostar unit on the

laboratory bench. To prevent machine malfunctions as a result of excessive dust, do not place

the unit near etcher catchers, micro etchers, or any area where extensive plasterwork will

occur. The air source should be within reach of the machine using the high-pressure hose as a

reference guide. Do not place the pressure line under the heater along the benchtop. The air

pressure should be capable of supplying a minimum of 87 psi. to the Biostar.

The following information provides a brief description of the computerized Biostar’s basic

components.

2

plug with fuse

compressed-air connection

pressure controller (regulator)

Heater

Locking Handle

Clamping Chamber

Pressure Chamber

Bar Code Scanner

Pellet Drawer