A/C MOUNTING with

SIDE PANEL “A”, “B”, and “C”

There are ten (10) air conditioners available for the GL840N12

enclosures.

The GL840N12 enclosures can come with one of three side panels that

will accept the following A/C units.

Side Panel “A” will accept:

GL2500V A/C Unit, 120V, 2500 BTU, 7.3 amps

GL3500V A/C Unit, 120V, 3500 BTU, 8.2 amps

GL4500V A/C Unit, 120V, 4500 BTU, 9.5 amps

GL6000V A/C Unit, 120V, 6000 BTU, 10.9 amps

Side Panel “B” will accept:

GL8000VHA A/C Unit, 120V, 8000 BTU, 14.7 amps,

designed for high ambient applications

GL10000V A/C Unit, 120V, 10,000 BTU, 15.1 amps

GL12000V A/C Unit, 120V, 12,000 BTU, 19.6 amps

Side Panel “C” will accept:

GL14000V AC Unit, 230V, 14000 BTU, 15.0/16.5 amps

GL17000V AC Unit, 230V, 17000 BTU, 15.5/17.1 amps

GL20000V AC Unit, 230V, 20000 BTU, 18.2/20a amps

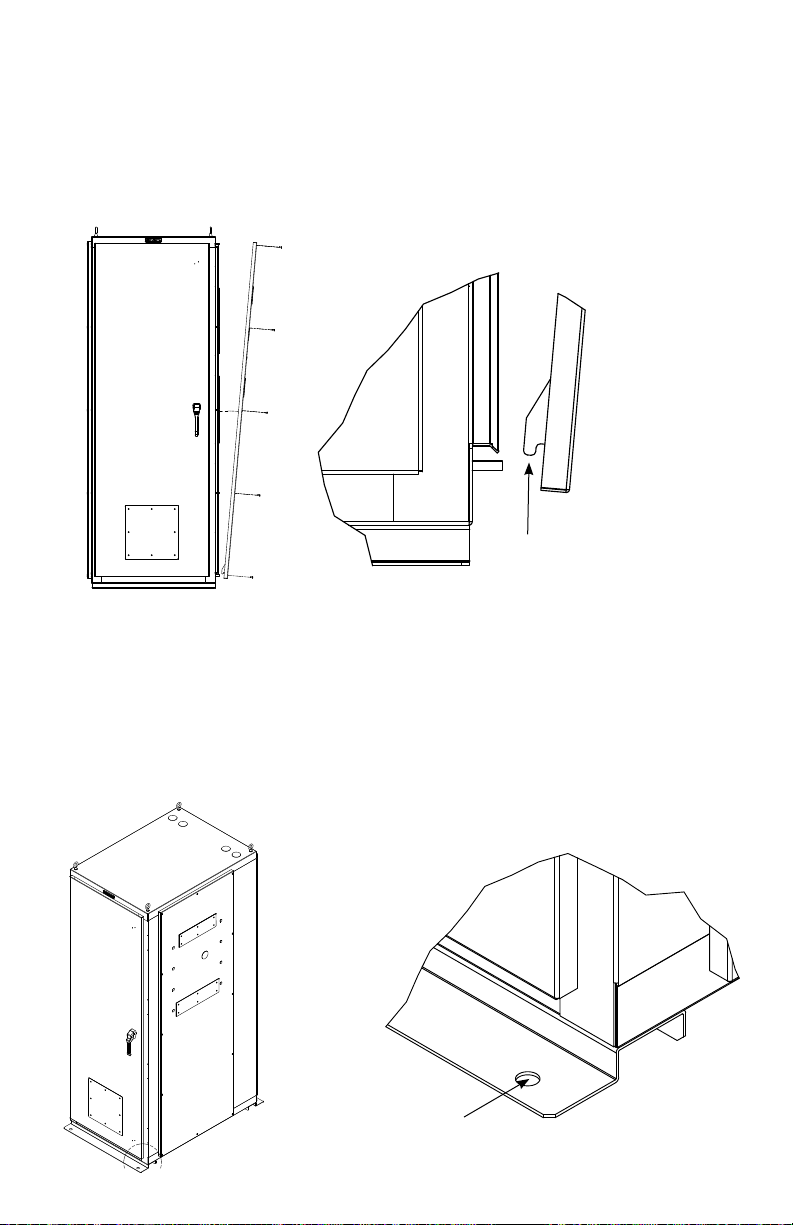

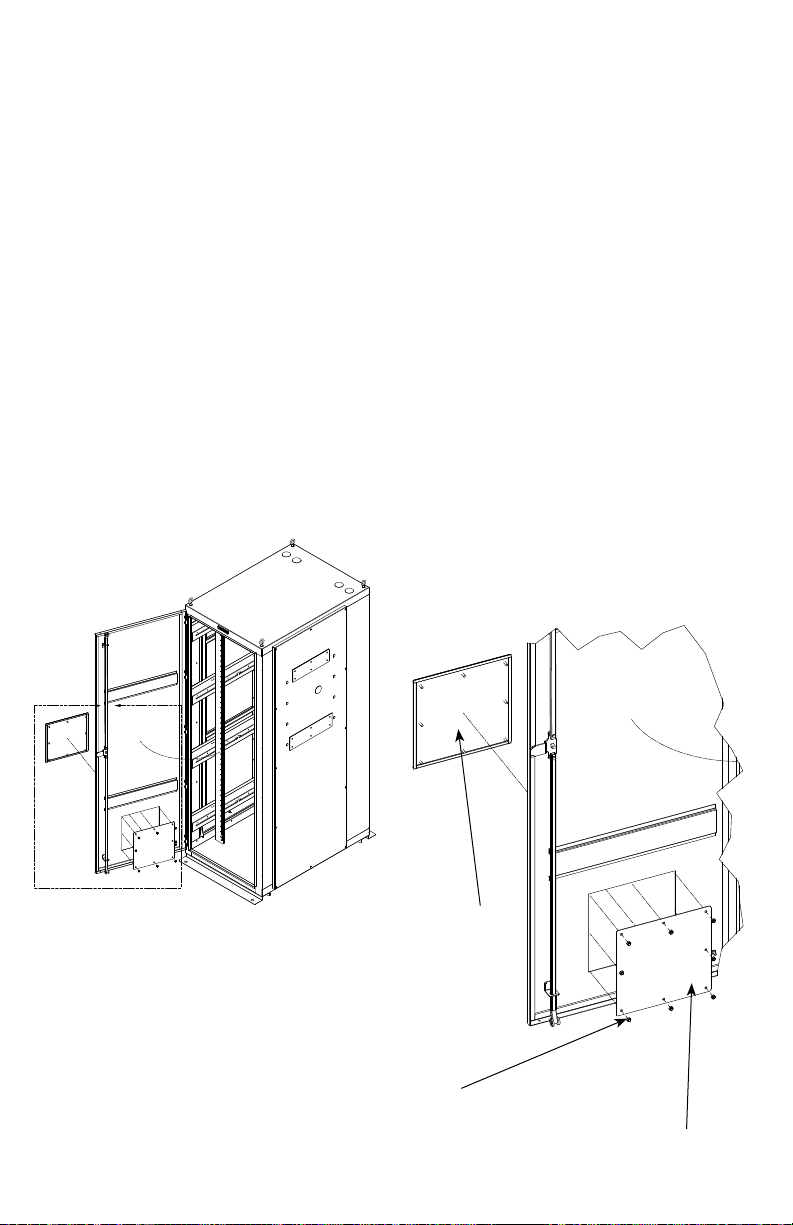

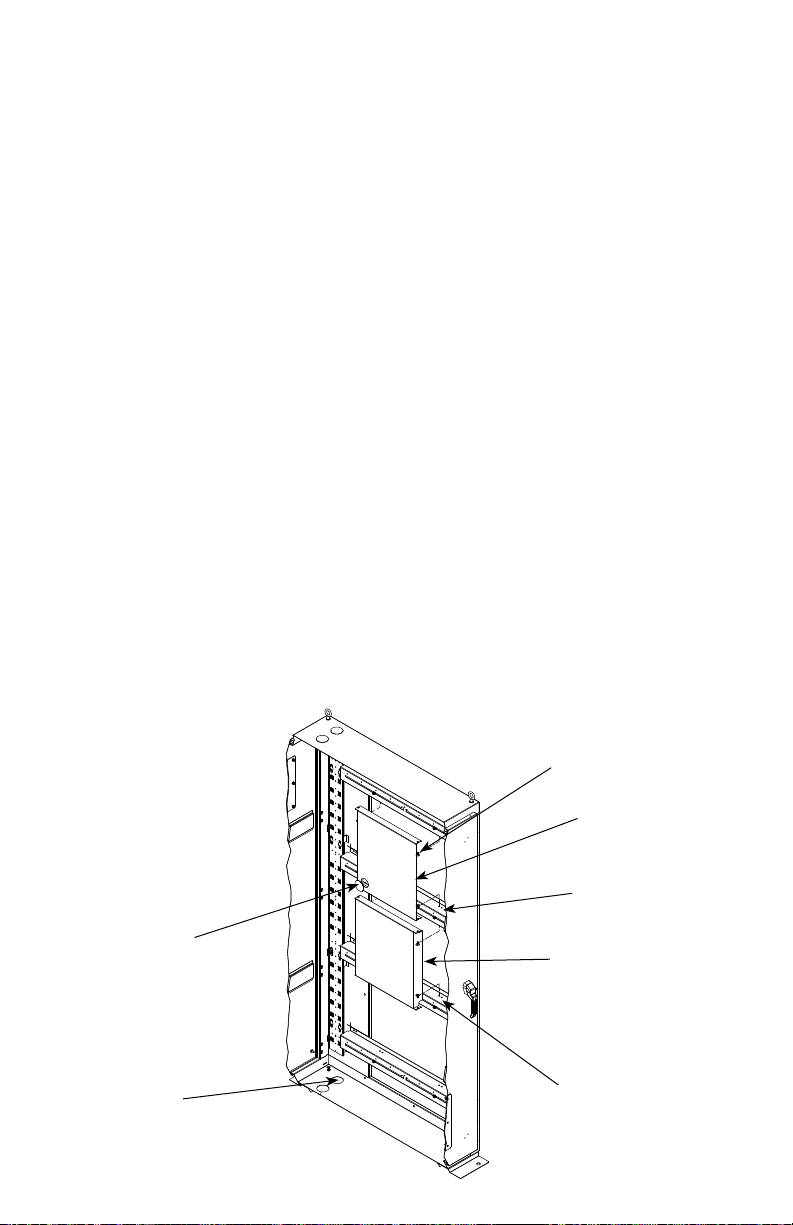

BAFFLE KIT

Each side panel comes with a bae kit that will be pre-installed at the

factory. There are two baes. One will direct conditioned air to the front

of the enclosure, the other will allow return air back to the A/C unit.

Button plug,

ush type

Ø 2"

Ø 2 3/8"

Electrical knockouts

x4 on bottom

x4 on top BOTTOM FRONT

Tuok panel

fastener

Top Bae for

30"W NEMA

Use rst hole

on horizontal for

placement

Note direction

of top and

bottom baes.

Crucial to proper

function of A/C

Use rst hole

on horizontal for

placement

10