2

PREFACE

This manual is provided to prevent service personnel from committing

an act that results in the risk of re, electric shock, or injury to persons.

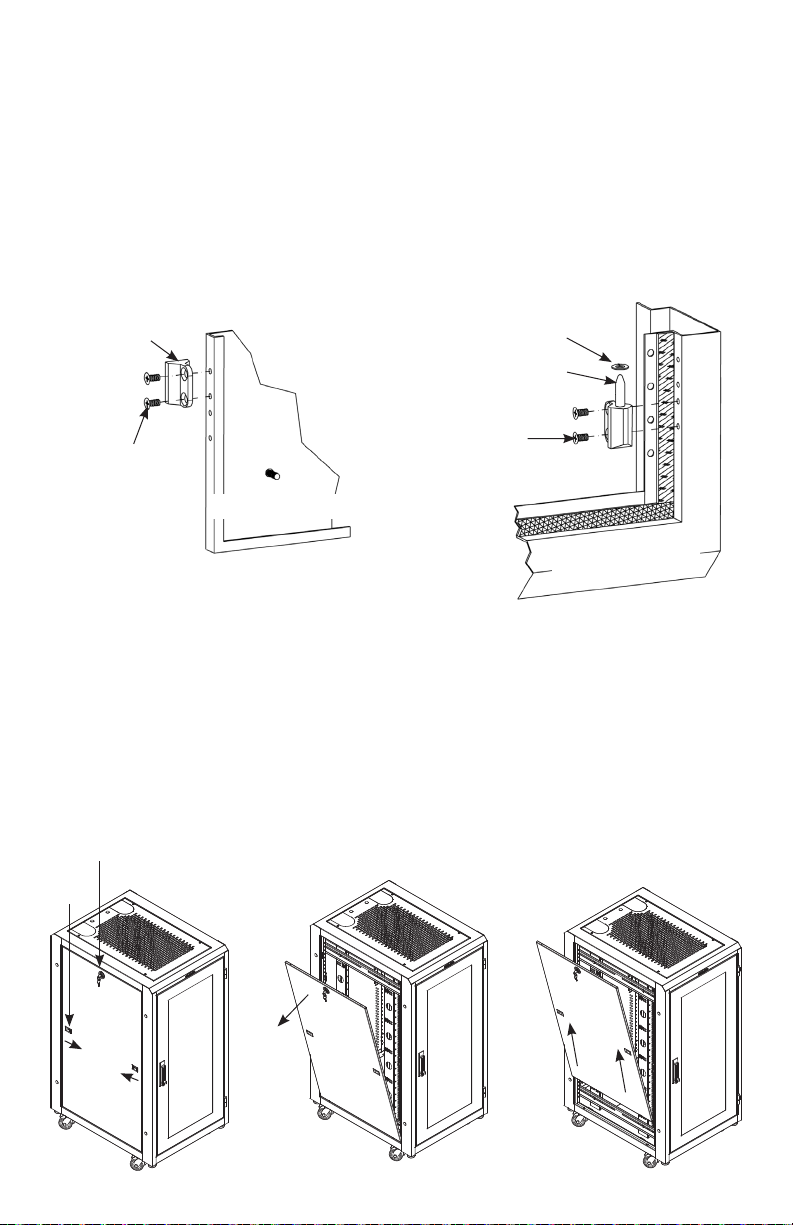

Only trained service personnel should receive, unpack, and assemble

the E cabinets. In addition, only trained service personnel should install

equipment in Cabinets.

SAFETY SYMBOLS USED IN THIS MANUAL

This manual provides general safety guidelines to be observed during

installation, operation, and maintenance of the E cabinet.

WARNING: Failure to follow directions in the warning could result in

injury to persons or loss of life.

CAUTION: Failure to follow directions in the caution could result in

damage to equipment or storage data.

SAFETY CONSIDERATIONS

WARNING: Improper handling and use of the E cabinet could result in

equipment damage, serious injury, or possible death.

Only trained service personnel should be used to remove the cabinet

from the pallet. Also, be sure you have a sucient number of service

personnel. Do not attempt to move cabinets by yourself.

Only UL® Listed ITE (Information Technology Equipment) units should

be installed inside the E cabinet.

Be sure to read and follow all individual manufacturer equipment

manuals for safety and installation instructions.

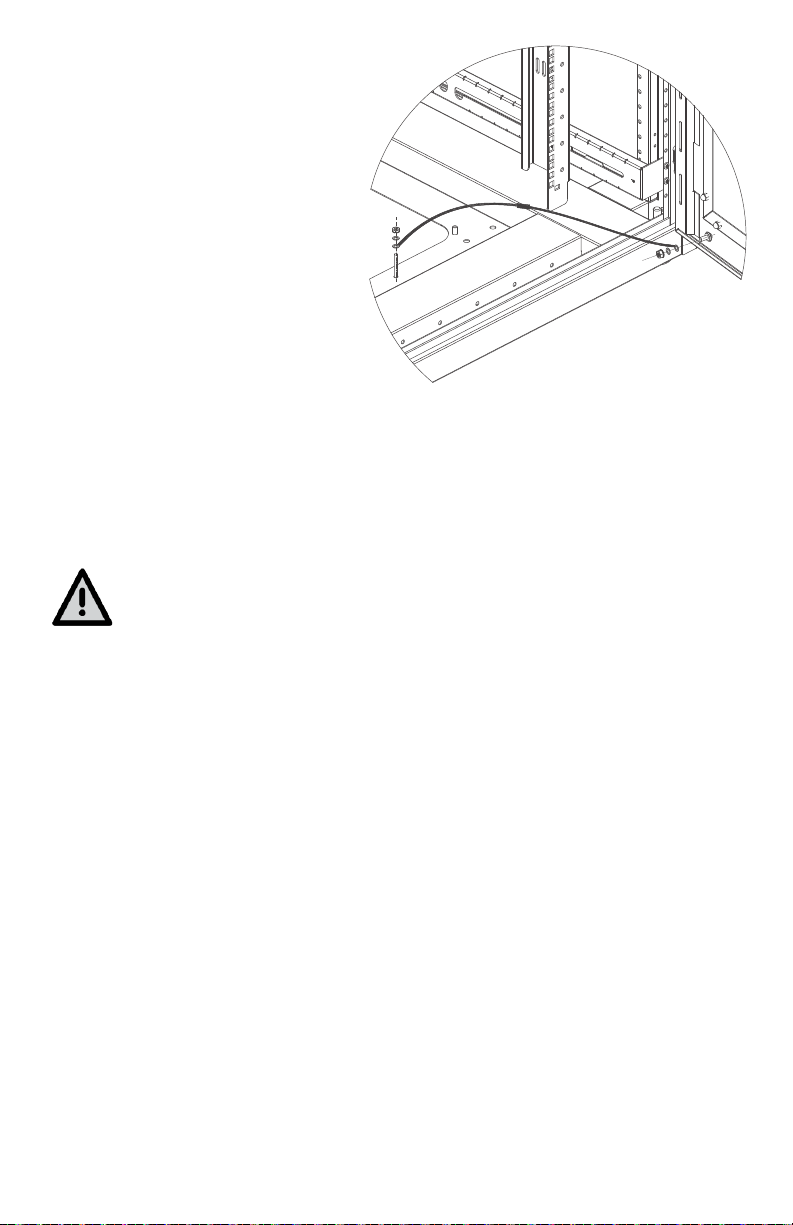

Proper spacing is required when installing electrical equipment

to avoid electrical shock. Maintain minimum spacing between the

accessories and components and the computer cabinet assembly for

safe operation of the equipment when installed in accordance with the

National Electric Code ANSI/NFPA 70-1999.

The ambient temperature operating range for the E cabinet and

accessories is +50 to +95° F (+10 to +35° C).

The non-operating temperature is -4 to +140° F (-20 to +60° C).