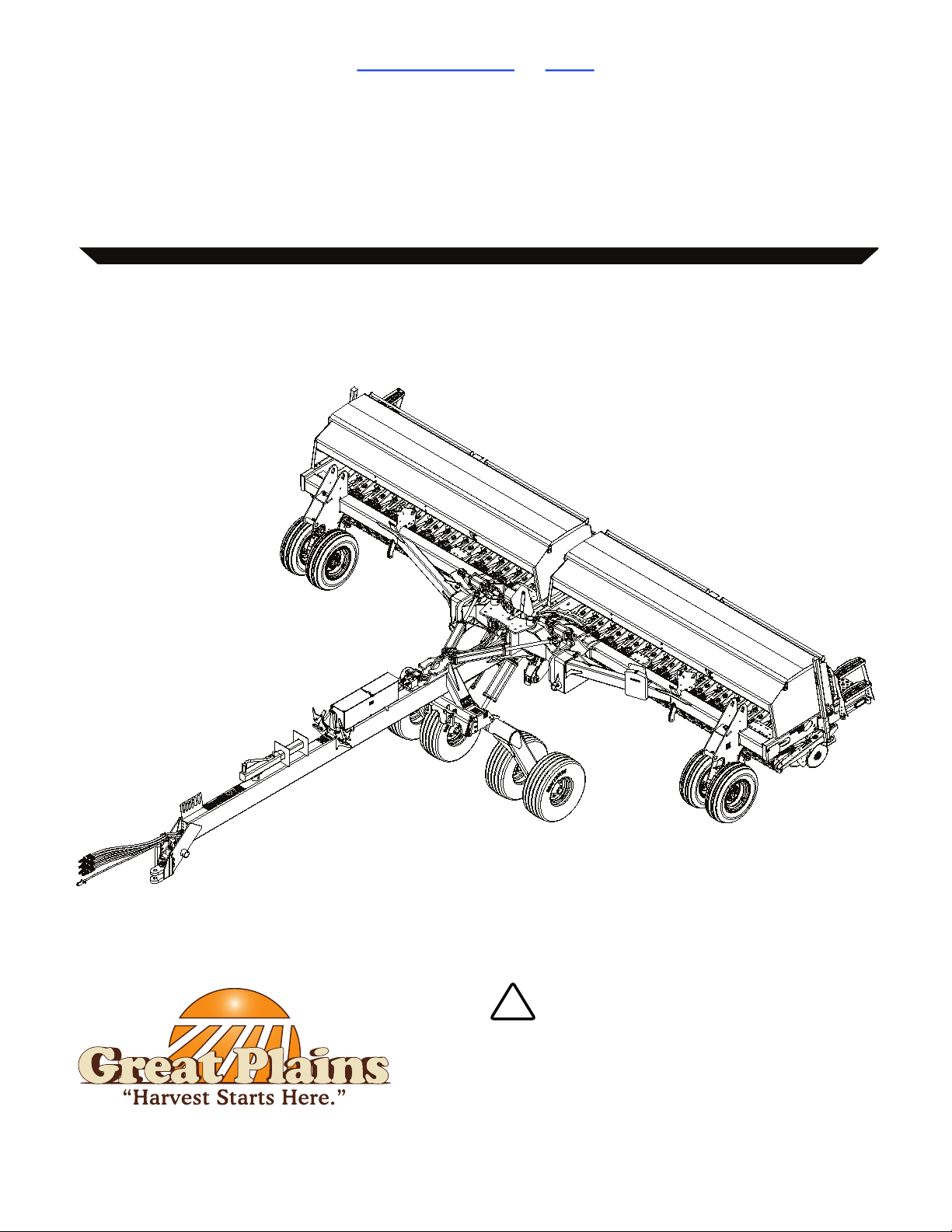

BD7600-26 Cover Index

Great Plains | 195-612M | 07/09/2021 vi

Touch800® Terminal (Option) . . . . . . . . . . . . . . 40

Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Parking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Parking with Drill Folded . . . . . . . . . . . . . . . . . . 40

Parking with Drill Unfolded . . . . . . . . . . . . . . . . 41

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Opener Adjustments . . . . . . . . . . . . . . . . . . . . . 42

Opener Leveling . . . . . . . . . . . . . . . . . . . . . . . . 42

Opener Frame Pivot Adjustment . . . . . . . . . . . 42

Opener Height . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Opener Spring Down Pressure. . . . . . . . . . . . . 44

Opener Depth Adjustment. . . . . . . . . . . . . . . . . 44

Disk Blade Adjustments . . . . . . . . . . . . . . . . . . 45

Disk Scraper Adjustment (Option) . . . . . . . . . . 45

Seed Firmer Adjustments. . . . . . . . . . . . . . . . . . 46

Keeton® Seed Firmer (Option) . . . . . . . . . . . . . 46

Seed-Lok® Firming Wheel (Option) . . . . . . . . . 46

Marker Adjustments . . . . . . . . . . . . . . . . . . . . . . 46

Marker Extension. . . . . . . . . . . . . . . . . . . . . . . . 46

Marker Disk Adjustment . . . . . . . . . . . . . . . . . . 47

Marker Chain Adjustment . . . . . . . . . . . . . . . . . 47

Marker Transport Carrier. . . . . . . . . . . . . . . . . . 48

Knock Down Adjustment . . . . . . . . . . . . . . . . . . 48

Tine Pitch Angle. . . . . . . . . . . . . . . . . . . . . . . . . 48

Knock Down Bar/Disk Gap . . . . . . . . . . . . . . . . 48

Scraper/Disk Gap . . . . . . . . . . . . . . . . . . . . . . . 49

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Hitches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Hydraulic Block Options . . . . . . . . . . . . . . . . . . . 50

Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Shaft Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Seed Firmers . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Seed-Lok® Firming Wheel . . . . . . . . . . . . . . . . 51

Keeton® Seed Firmer . . . . . . . . . . . . . . . . . . . . 51

HD Narrow Disk Scraper . . . . . . . . . . . . . . . . . . 51

Disk Scraper Installation . . . . . . . . . . . . . . . . . . 51

Press Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Press Wheel Scrapers . . . . . . . . . . . . . . . . . . . . 52

Seed Hoses/Fertilizer Tubes . . . . . . . . . . . . . . . 52

Blockage Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Box Divider Insert. . . . . . . . . . . . . . . . . . . . . . . . 52

Scale Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Touch800® Console Kits . . . . . . . . . . . . . . . . . . 53

Work Light Kit. . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Fertilizer Tank . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Knock Down Kit . . . . . . . . . . . . . . . . . . . . . . . . . 54

Camera Package . . . . . . . . . . . . . . . . . . . . . . . . 54

Topcon Console System . . . . . . . . . . . . . . . . . . 54

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . 55

Regular Maintenance . . . . . . . . . . . . . . . . . . . . . 55

Hydraulic Maintenance . . . . . . . . . . . . . . . . . . . . 56

In-Line Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Material Clean-Out . . . . . . . . . . . . . . . . . . . . . . . 56

Flow Tent Replacement . . . . . . . . . . . . . . . . . . . 57

Feed Cup Maintenance . . . . . . . . . . . . . . . . . . . 57

Feed Cup Removal . . . . . . . . . . . . . . . . . . . . . . 57

Feed Cup Installation . . . . . . . . . . . . . . . . . . . . 58

Seed Wheel. . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Feed Cup Flap . . . . . . . . . . . . . . . . . . . . . . . . . 59

Chains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Chain Clips . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Marker Shear Bolt . . . . . . . . . . . . . . . . . . . . . . . 60

Marker Disk Lubrication . . . . . . . . . . . . . . . . . . 60

Ground Drive Gearbox . . . . . . . . . . . . . . . . . . . . 60

Hydraulic Drive . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Knock Down Maintenance . . . . . . . . . . . . . . . . . 61

Seed Flap Replacement. . . . . . . . . . . . . . . . . . . 61

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Grease Fittings . . . . . . . . . . . . . . . . . . . . . . . . . 62

Wheel Bearings. . . . . . . . . . . . . . . . . . . . . . . . . 62

Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . 63

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Torque Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Tire Information . . . . . . . . . . . . . . . . . . . . . . . . . 67

Electrical Harness Routing . . . . . . . . . . . . . . . . . 68

Lighting Harness . . . . . . . . . . . . . . . . . . . . . . . . 68

Hydraulic Diagrams . . . . . . . . . . . . . . . . . . . . . . 68

Fold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Lift, Wing Flex, and Hydraulic Jack . . . . . . . . . 69

Opener Lift with Open Center (S/N E1029-) . . 70

Opener Lift with Open Center (S/N E1030+) . . 70

Opener Lift with Closed Center (S/N E1029-) . 71

Opener Lift with Closed Center (S/N E1030+). 71

Hydraulic Drive Single Box Configuration . . . . 72

Hydraulic Drive Split Box Configuration . . . . . . 73

Section Control . . . . . . . . . . . . . . . . . . . . . . . . . 74

Ground Drive Configuration . . . . . . . . . . . . . . . 74

Hydraulic Drive Configuration (S/N E1029C-) . 74

Hydraulic Drive Configuration (S/N E1030C+). 75

Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Single Marker Configuration . . . . . . . . . . . . . . . 76

Dual Marker Configuration . . . . . . . . . . . . . . . . 76

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77