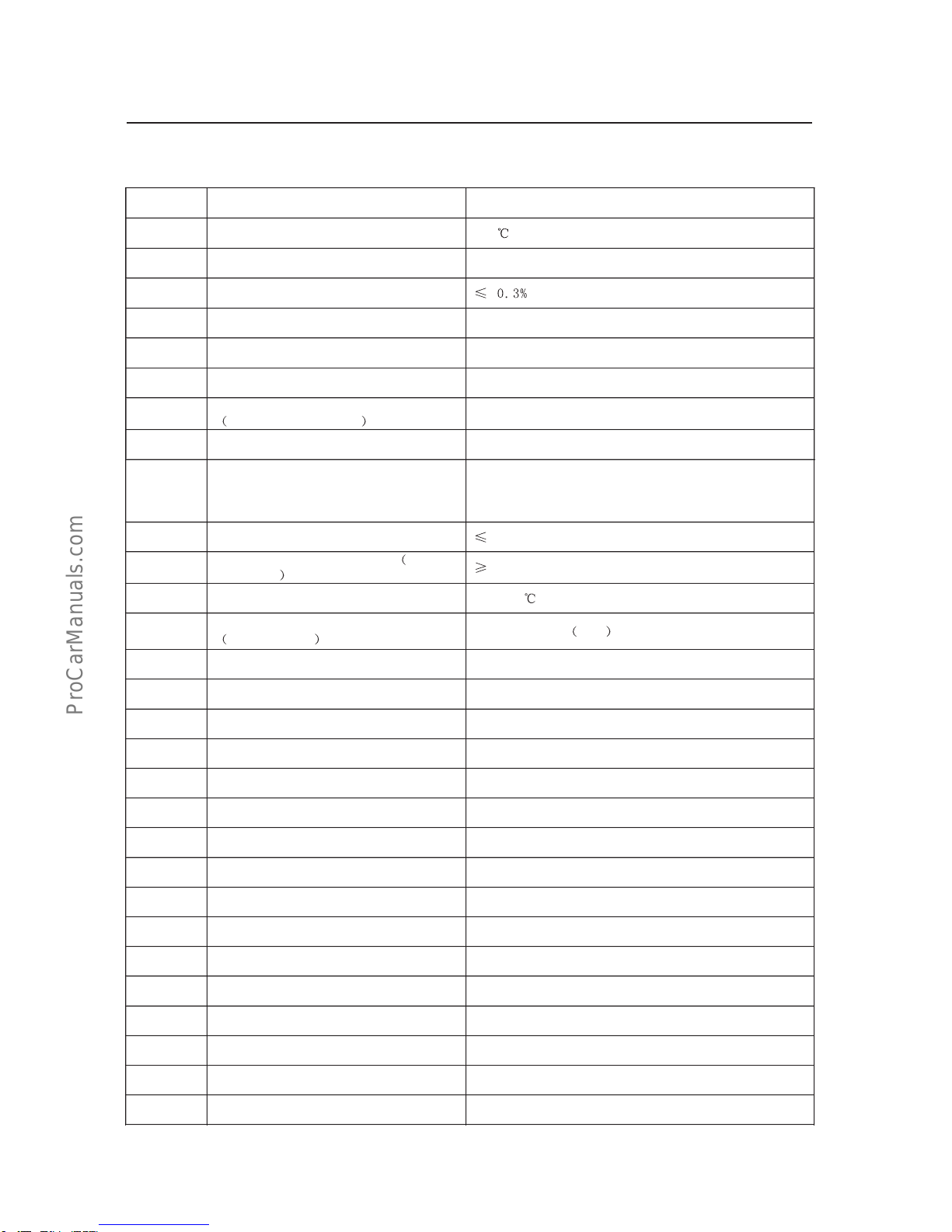

GI-2

Key technical parameters for Model GW491QE petrol engine

S.N. Item Specification and parameters

1 Model Model GW491QE

2 Pattern Four-cylinder, inline, water-cooled, overhead valve,4-stroke

petrol engine

3 Fuel supply pattern Electronic controlled jet injection by group at multiple points

4 Measurement method for air intake

amount Velocity &density type

5 Pattern of combustion chamber Wedge typed

6 Diameter of cylinder bore 91mm

7 Piston stroke 86mm

8 Displacement 2.237L

9 Compression ratio 8.8:1(European class-II)9.1:1European class-III

10 Rated power 78kw/4600 r/min(European class-II)

78kw/4600 r/min(European class-III)

11 Max. torque 190·m/2400~2800 r/min

12 Min. fuel consumption rate ≤265g/kw·h(European class-II)≤250g/kw·h(European

class-III)

13 Fuel specRONNot lower than 93#GB17930-1999

14 Stable idle-speed 750±50r/min

15 Idle-speed control pattern Electronically closed-loop control

16 Piston average velocity 13.18m/s

17 Average valid pressure 874kpa

18 Compression pressure of cylinder

when at 250r/min1128kpa(European class-II); 1350kpaEuropean class-III

19 Ignition sequence 1-3-4-2

20 Ignition control pattern Without ignition distributor, and direct ignition under an

electronic control

21 Spark plug clearance 1.0~1.2mm

22 Model of spark plug F6RTC

23 Valve clearance 0mmhydraulic tappet

24

Valve timing:

Inlet-valve open lead angle;

Inlet-valve close lag angle;

Exhaust-valve open lead angle;

Exhaust-valve close lag angle;

12°before the top dead center,

48°before the bottom dead center;

54°before the bottom dead center;

10°before the top dead center;

25 Pattern of lubrication A combined pattern of pressure and splash.

26 Oil spec SG grade machine oil API10W-40GB11121-1995for petrol

engine

27

Main passage oil pressure

When at idle-speed 750±50r/min

or 3000r/min

49 kpa

(245-490) kpa

28 Oil capacity 4.2L

29 Oil temperature (85~90)℃

Engine service /maintenance data-Key technical parameters for Model GW491QE petrol engine

ProCarManuals.com