Air Inlet and Exhaust

System

i06515116

Air Inlet and Exhaust System

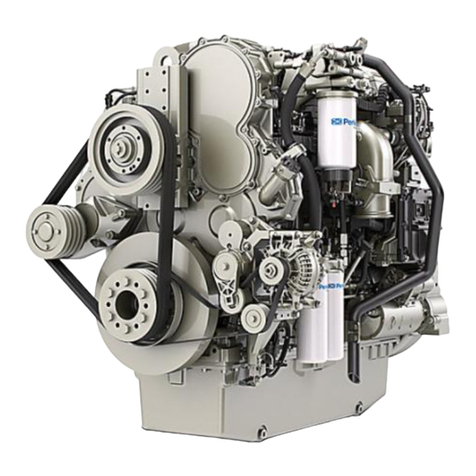

The components of the air inlet and exhaust system

control the quality and the amount of air that is

available for combustion. There are two separate

turbochargers that are installed on the rear of the

engine.

The hot charge air from the turbochargers is directed

by large air pipes to the aftercooler. The cooling of

the charge air is achieved by inserting this additional

radiator in front of the normal radiator that cools

water. The single radiator fan pushes air through

each matrix in series. The air passes through the

matrix for charge air. After the air passes through the

radiator for charge air, the air is directed through

pipes that have a large bore to the air intake

manifolds.

The camshaft controls the movement of the valve

system components and injectors.

Illustration 1 g01188937

Air Inlet And Exhaust System

(1) Exhaust manifold

(2) Aftercooler

(3) Engine cylinder

(4) Air inlet

(5) Turbocharger compressor wheel

(6) Turbocharger turbine wheel

(7) Exhaust outlet

Clean inlet air from the air cleaners is pulled through

air inlet (4) into the turbocharger compressor by

compressor wheel (5). The rotation of the

compressor wheel compresses the air. The rotation

of the turbocharger compressor wheel then forces

the air through a tube to aftercooler (2). The

aftercooler lowers the temperature of the

compressed air before the air enters the inlet

chamber in each cylinder head. Air flow from the inlet

chamber into the cylinder heads is controlled by the

inlet valves.

There are two inlet valves and two exhaust valves for

each cylinder. Refer to Systems Operation, “Valve

Mechanism”. The inlet valves open when the piston

moves down on the inlet stroke. The cooled,

compressed air is forced into the cylinder from the

inlet chamber.

The inlet valves close and the piston starts to move

up on the compression stroke. When the piston is

near the top of the compression stroke, fuel is

injected into the cylinder. The fuel mixes with the air

and combustion starts. The force of the combustion

pushes the piston downward on the power stroke.

When the piston moves upward again, the piston is

on the exhaust stroke. The exhaust valves open and

the exhaust gases are pushed through the exhaust

port into exhaust manifold (1). After the piston makes

the exhaust stroke, the exhaust valves close and the

cycle starts again.

Exhaust gases from exhaust manifold (1) go into the

turbine side of the turbocharger. The exhaust gases

cause turbine wheel (6) to turn. The turbine wheel is

connected to the shaft that drives the turbocharger

compressor wheel (5). The exhaust gases exit

through exhaust outlet (7).

i02856821

Valve Mechanism

The valve system components control the flow of the

inlet air and the exhaust gases into the cylinders and

out of the cylinders during engine operation.

The crankshaft gear drives the camshaft gears

through idlers. The camshaft must be timed to the

crankshaft in order to get the correct relation between

the piston and the valve movement.

The camshaft has three lobes for each cylinder. Two

lobes operate the valves and one operates the fuel

injector.

As the camshaft turns, the lobes on the camshaft

cause lifters to move up and down. This movement

causes pushrods to move rocker arms. The

movement of the rocker arms cause bridge pieces to

move downward. The bridge pieces open two valves

simultaneously. The valves can be either inlet valves

or exhaust valves. There are two inlet valves and two

exhaust valves for each cylinder.

M0064276 5

Air Inlet and Exhaust System