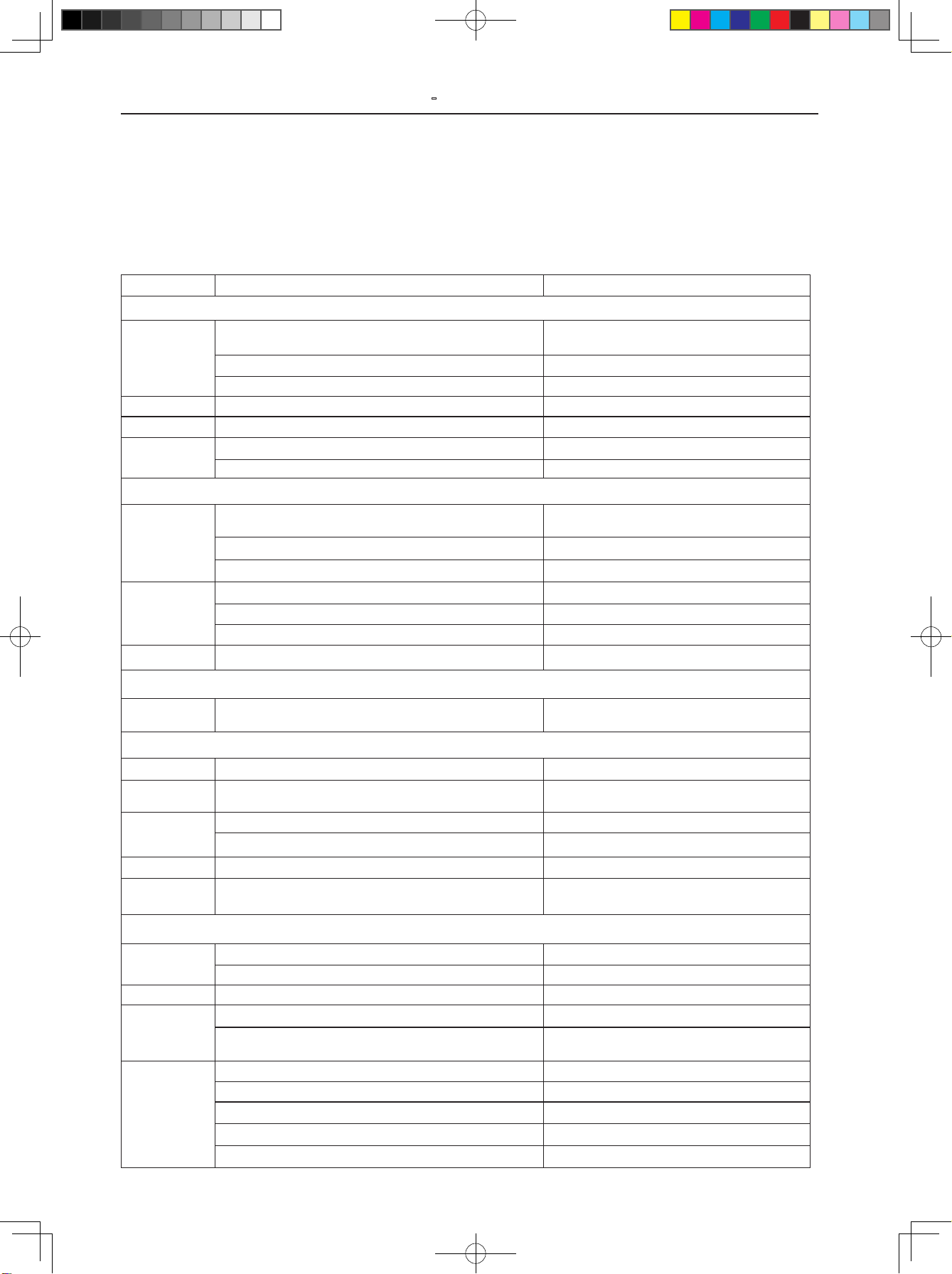

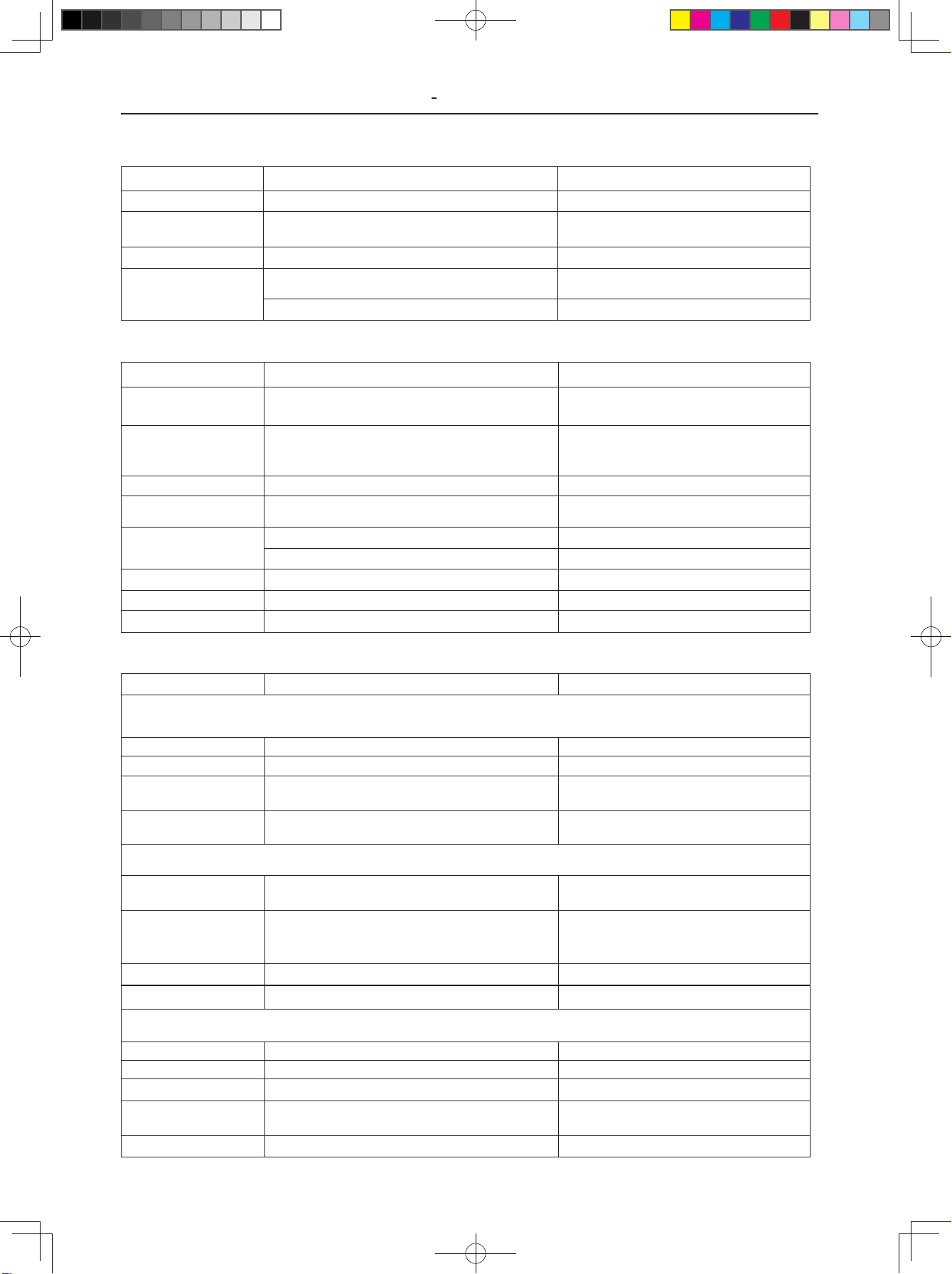

Examination Causes Corrections

4. Fast startup system

Preparations:

1.Disconnect lead socket joint of the temperature switch.

2.Determine if the preheating plug is switching

(a)Ensure the starting switch is “opened”

(b)Connect the cylinder wall and any preheating plug with a voltmeter

(c)Turn the starting switch to “close” position.

If the preheating plug is switching, the voltmeter will display voltage (12V)

If the voltmeter nger does not move, it means that the preheating plug is not switched

3.Failure repair

The preheating plug is switching

The indicating light of the

preheating plug is not on

Indicating light bulb damage Replace the bulb

Fast starting timer Fast starting timer damage Replace the fast starting timer

The indicating light of the

preheating plug is on for 0.3

second

Fast starting timer damage Replace the fast starting timer

The indicating light of the

preheating plug is on for 3.5

second

Turn the starting switch from “start” back to

“close” after the engine has been started, if

the preheating plug relay keeps closing for

less than 14 seconds, then it indicates that the

fast starting up timer is damaged.

Replace the fast starting timer

Turn the starting switch from “open”

to “close” , if the preheating plug relay

keeps closing for less than 14 seconds,

then it indicates that the fast starting up

timer is damaged.

Replace the fast starting timer

temperature switch Temperature switch damage Replace the temperature switch

Preheating plug connection Preheating plug not connected Replace the preheating plug

The preheating plug is not connected

The indicating light of the

preheating plug is not on Indicating light fuse broke Replace the fuse

Fast starting timer Fast starting timer damage Replace the fast starting timer

The indicating light of the

preheating plug is on for 3.5

second

Preheating plug relay damage The

preheating plug is not switching when

the starting switch turns from “open” to “

close”.

Replace the preheating plug

Preheating plug relay wires damage Repair or replace the wires

Damage of fuse or wires The preheating

plug is switching when the starting switch

turns from “open” to “close”.

Replace the fuses or wires

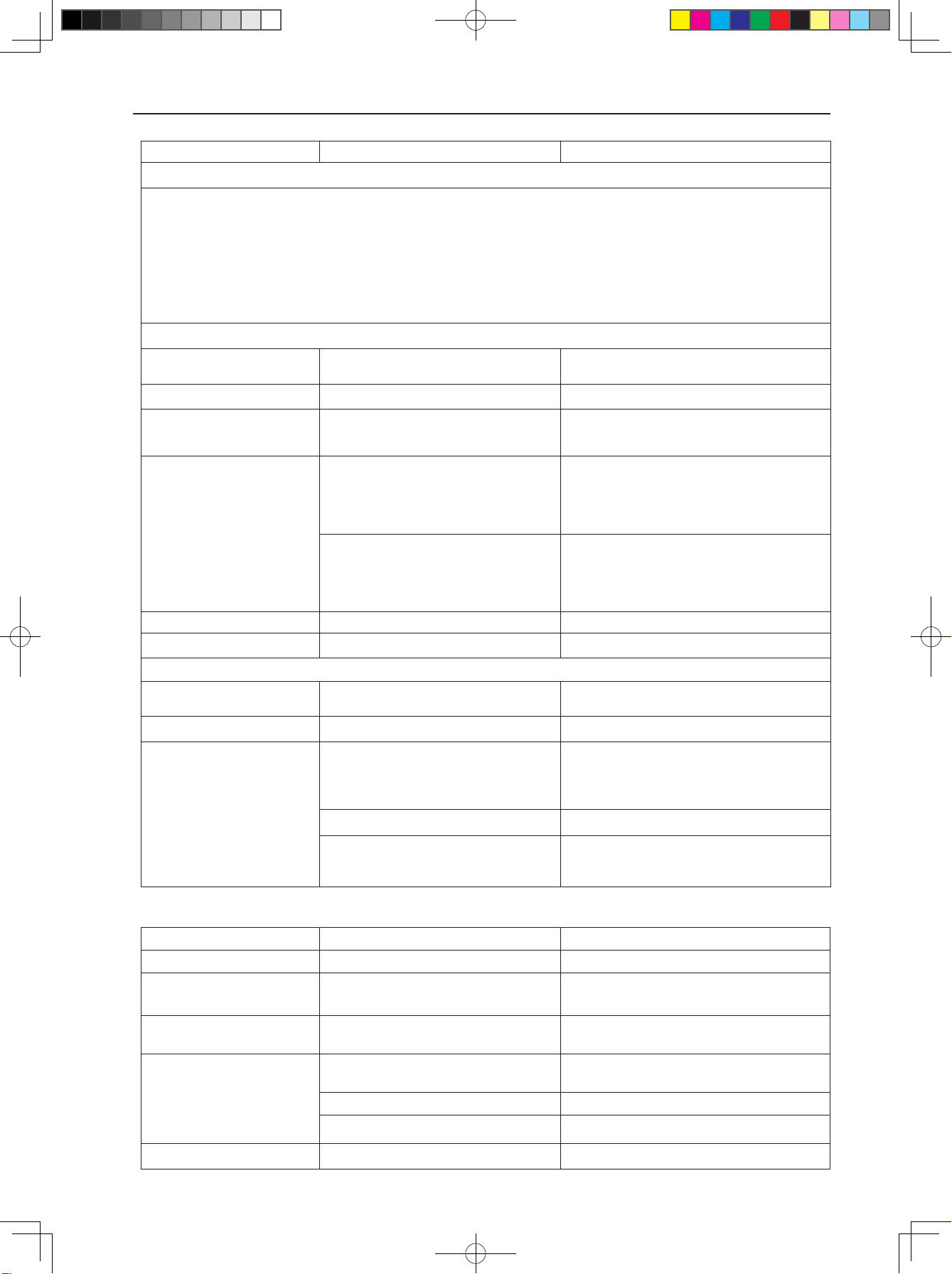

2.Unstable idle speed

Maintenance documents-Fault diagnosis and troubleshooting

Examination Causes Corrections

Idle speed system Idle speed improper adjustment Adjust the idle speed

High idle speed controlling

apparatus

High idle speed controlling apparatus

damage

Repair or replace the high idle speed

controlling apparatus

Throttle valve control

system Throttle valve control system damage Repair or replace the throttle valve control

system

Fuel system

Fuel leakage of blockage of the fuel

system Repair or replace the fuel system

Air in the fuel system Let air in the fuel system out

Water in the fuel system Replace fuel

Fuel lter Fuel lter elements blockage Replace the fuel lter elements