6

Operating Instructions

Top with clean, regular unleaded petrol only. Do Not Overll. Do not ll above the high level mark on the tank. Make

sure that the petrol is free from impuries, parcularly water. The petrol tank is located inside the engine

compartment. Raise the bonnet for access. Before removing the ller cap from the fuel tank to refuel the machine,

wipe or brush the area clean to prevent any dirt or debris from accidentally falling into the tank when the cap is

removed. Do not use stale petrol in your mower - add clean, fresh fuel only.

Before Starting - Please Do Not Proceed Before Reading Safety Instructions.

Fuel

Check oil level by posioning the mower on level ground. Wipe or brush the area clean around the oil ller/ dipsck

cap, remove the dipsck and wipe clean, replace the dipsck - screwing carefully into posion. Remove again and sight

the oil level. Fill to the full mark. Do not overll. The dipsck must be rmly in place when the engine is running. Refer

to Crankcase Lubricaon pg.10 for oil recommendaons.

Engine oil

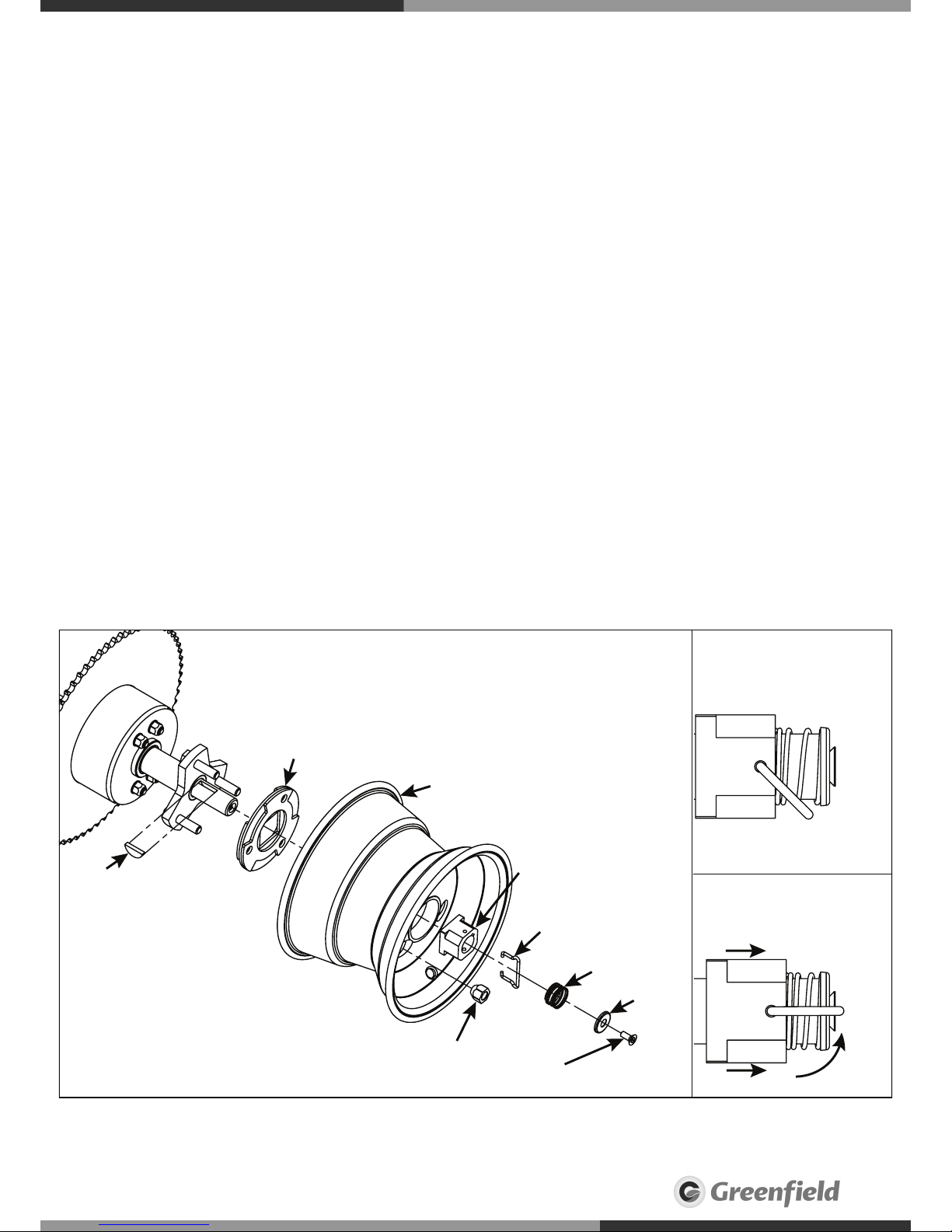

Inate to the correct pressure, 20 to 22 psi (140 to 154 KPa) in the front tyres and 12 to 15 psi (84 to 105 KPa) in the

rear tyres. Do not over inate. Over inaon will change the shape of the tyre, adversely aecng the cuer trim and

lt, and may also cause permanent tyre damage, resulng in tyre rupture and possible accident.

Tyres

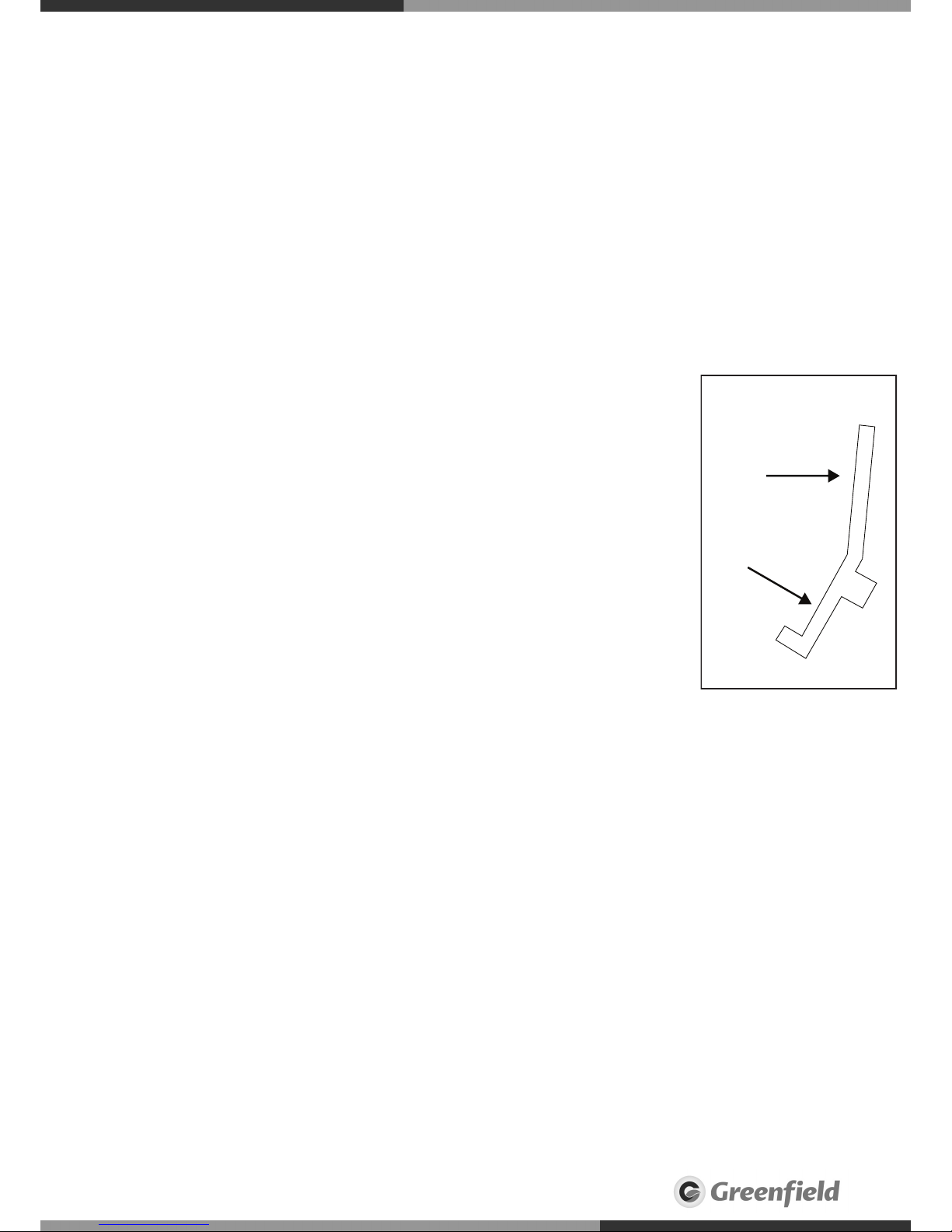

The cung height adjustment lever is located in the rear cover to the front of the operator. To alter the cung height,

move the lever to the right then shi upward or downward to select the seng, then release to lock in posion. An

indicator panel displays the seng. Use the height seng in the green band for maximum belt life.

Cutting Height

The blade clutch switch is located on the right hand side of the dash panel. To ENGAGE the cuer blades, pull the

switch up. To DISENGAGE the cuer blades, push the switch down.

DANGER:

• When cuer clutch is engaged, high-speed blades are rotang.

• Never use the mower without the safety deector or grass catcher ed.

• Never aempt to dismount from the driver’s seat while engine is running.

Blade Clutch

The operator’s seat is adjustable front to rear. To adjust, push the lever on the le hand side of the seat to the le and

slide the seat forward or backward unl a safe and comfortable seang posion is obtained, then release the lever to

the locked posion. Oil the slides occasionally. The seat is ed with a safety switch. See Tesng Procedure pg.3.

Seat

Apply the park brake, disengage the blade clutch (cuers out). Turn on fuel tap (if ed). For cold starng, the choke

will need to be acvated. On single cylinder models, move the throle control lever up and into the CHOKE posion.

On twin cylinder models ed with a separate choke control, move the throle control to the FAST posion and pull

out and hold the choke control in the choke posion. Turn the starter key to the start posion for a maximum of ten

(10) seconds, to avoid overheang the starter motor. If the engine does not start, it may be ooded. Set the throle

control half way and try again.

Make sure to return the key to the RUN posion aer the engine starts or each me you aempt to start it. Once the

engine is running, move the throle control to the FAST posion on single cylinder models to turn o the CHOKE.

On twin cylinder models with separate choke control, push the CHOKE in fully for correct engine operaon.

To Start The Engine

Important - This Greeneld mower is ed with a safety ‘Cut-Out’ switch, acvated by the seat. The operator must

be seated to start the engine and remain seated while operang the mower. If the operator does not remain seated,

the engine will stop. This safety switch must be kept funconing for your protecon. Adjustment is easily done when

necessary.