2.5 MOTORS

General: Condenser fan motors shall be as described above (Section 2.3, subsection J). Blower

motor shall be energy-efficient [ODP][TEFC]and comply with EPACT standards for single speed

ODP and TE enclosures. Motor shall be heavy-duty, permanently lubricated type to match the fan

load and furnished at the specified voltage, phase and enclosure. Drives shall be sized for a

minimum of 150% of driven horsepower and pulleys shall be fully machined cast-type, keyed and

fully secured to the fan wheel and motor shafts. Electric motors of ten horsepower or less shall be

supplied with an adjustable drive pulley. Comply with requirements in Division 23 05 13, matched

with fan load. Motors shall be Select one [60 cycle, 3 phase 208 volts] ,60 cycle, 3 phase 230

volts] [60 cycle, 3 phase 460 volt].

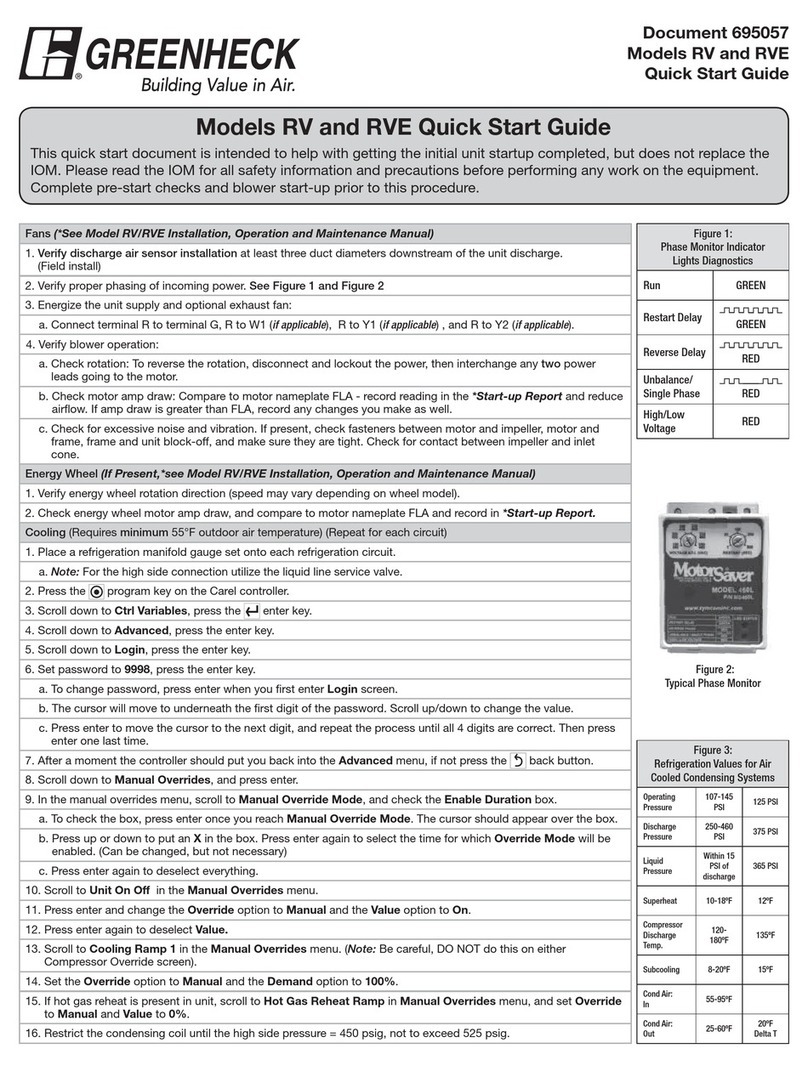

2.7 UNIT CONTROLS: Other than when a unit is retrofitted into an existing building control system or

otherwise configured to be controlled by an owner-supplied building controller, the MAU must be

ordered with a microprocessor controller. See IOM / Controls The MAU shall be constructed so

that it can function as a stand-alone cooling system controlled by factory-supplied controllers,

thermostats and sensors or it can be operated as a cooling system controlled by a Building

Management System (BMS). This Makeup Air unit shall be controlled by a factory-installed

microprocessor programmable controller that is connected to various optional sensors that may

have either analog or digital output.

1. A Microprocessor Controller known as a DDC shall be capable of receiving and

amplifying either digital or analog inputs from internal sensors or from a BMS. The

DDC shall be equipped with a large LCD display showing operating states, owner

specified settings and alarm conditions. Owner-specified ventilating conditions can

be input by means of pushbuttons. [RoomTemperature sensors][DDC Remote

Interface (room display)] The DDC shall have 4 MB flash memory capacity, pre-set

for a programming key, shall be modem/modem GSM/SMS ready, have 5 analog

inputs, 2 PT1000 inputs, 3 each 0 to 10 VDC inputs, 3 each 0 to 20 ma inputs, 5

NTC inputs, 3 each 0 to 5 VDC ratiometric inputs, AIN setting by software, 8 digital

inputs, 2 contact points, 8 each 24 VDC/VAC inputs, 4 analog outputs, 8 each

digital outputs, 7 SPST relay outputs, 1 SPDT relay outputs and 2 SSR outputs.

2. Operating protocol: The DDC shall be factory-programmed for (LonWorks][BACnet

MSTP][BACnet IP][Modbus]. Specify protocol.

3. [Variable Frequency Drive (VFD)][MAU shall have factory installed variable

frequency drive for modulation of the Supply Air blower assembly

The following devices are all optionally available for installation in the field. For

further information on specific devices, see the IOM: Field installed Control Sensors

4. [DDC Room Interface: Contractor shall provide and install Indicate quantity room

display(s) that function as remote indicators of owner-selected operating

parameters and also permit remote input of new operating parameters. Each room

display unit shall have a large LCD user interface screen similar in form and

function to the screen on the DDC. Installed location of room display(s) shall be as

indicated on the plans.] Note: only one room display per MUA is available.

5. [Dehumidistat: Contractor shall provide and install a dehumidistat as indicated on

the plans.]

6. [Room / Space Temperature Sensors: Contractor shall provide and install a room

temperature sensor as indicated on the plans]

7. [Dirty filter sensor]

8. [CO2 Sensor: Contractor shall provide and install a CO2 sensor as indicated on

the plans]

9. [Fire Stat Type III: Contractor shall provide and install a Type II Fire Stat as shown

on the plans]

10. [Industrial Remote Panel: Contractor shall provide and install a remote panel that

displays unit operating conditions and has enabling switches for system functions.

Remote panel is to be installed as shown on the plans. [Remote panel shall have a

DDC Room Display built in to provide for remote inputting of operating

parameters]]See IOM: Field Installed Control Sensors / Remote Operating Panel.

Product Specifications: Packaged Outdoor Heating and Cooling Make-Up Air Conditioners with Packaged DX (08/10) Page 6 of 7

Copyright © 2010 Greenheck Fan Corporation