Sure-Aire™ Flow Monitoring System4

Air Flow Units: Press “Edit” to change Air Flow Units.

Press “Prev” or “Next” to adjust, then press Enter to

store the value.

• CFM (default)

• m³/hr

• m³/min

Pressure Units: Press “Edit“ to change pressure units.

Press “Prev“ or “Next“ to adjust, then press “Enter“ to

store the value.

• In. wg (default)

• Ft wg

• mm wg

• cm wg

• PSI

• In. Hg

• mm Hg

• mBar

• Pa

• kPa - kilopascals (1kPa = 1000 Pa)

• hPa - hectopascals (1hPA = 100 Pa)

• Oz. In.

Temperature Compensation: Press “Edit“ to change

Temperature Compensation. Press “Prev“ or “Next“ to

adjust, then press “Enter“ to store the value.

• Yes (default)

• No

Note: If temperature compensation is set to “No“, the

air density will be a function of standard temperature

(70°F / 21°C).

Analog Output Signal: Press “Edit“ to change Output

Signal type. Press “Prev“ or “Next“ to adjust, then press

“Enter“ to store the value.

• 4-20 mA (default)

• 2-10 VDC

Linearize By: Press “Edit“ to change the linearization

settings. The electronics will linearize the electronics

output with respect to this setting.

• Flow (default)

• Pressure

Note: The maximum measurable flow rate will

automatically calculate based on the electronics

settings. The maximum flow rate is displayed on the

screen.

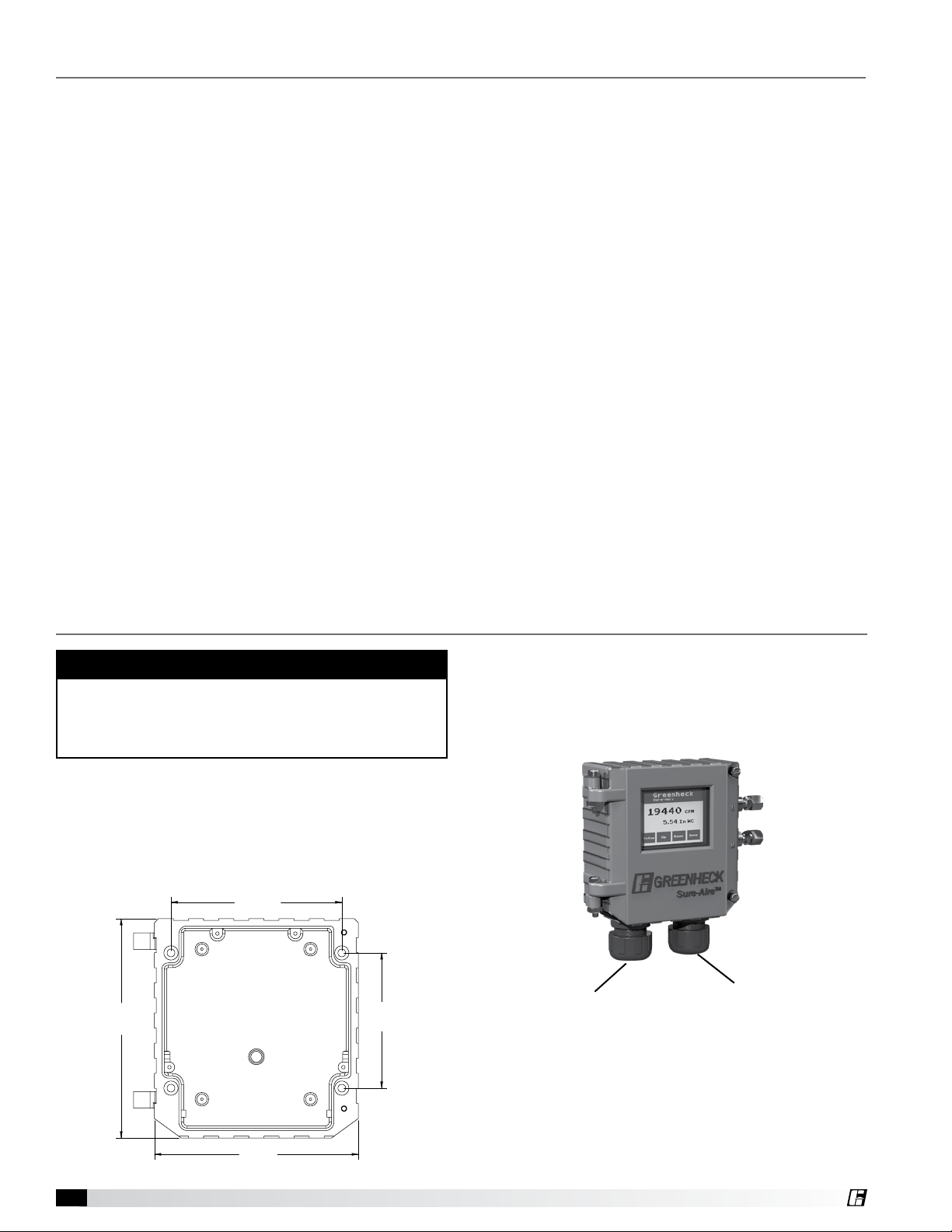

Navigation Buttons

The electronics is equipped with a touchscreen LCD

display. There are 4 navigation buttons on the bottom

of the screen. Button names will change based on the

parameter you are in (i.e. “Setup” will change to “Home”

and “Home” will change to “Edit”).

Home Screen

To view the different settings use the “Up” and “Down”

buttons to scroll through the list. To adjust settings,

press “Setup” and scroll through the settings. Below is

information on the adjustable settings.

Settings Menu

Home Screen: Top/Bottom View: Press “Edit“ to

change Main Display Value. Press “Prev“ or “Next“ to

adjust what reading displays on the Home screen, then

press “Enter“ to store the value.

• Flow (default)

• Pressure

• Temperature

• Air density

• Output signal (default bottom display)

• Velocity

• None

Measurement System: Press “Edit“ to change the

measurement system units. Press “Prev“ or “Next“ to

adjust, then press “Enter“ to store the value.

• English (default)

• Metric

K-Factor: Press “Edit“ to change K-Factor. Press “Inc“

or “Dec“ to adjust, then press “Enter“ to store the value.

• 200 to 30,000

Elevation: Press “Edit“ to change elevation. Press “Inc“

or “Dec“ to adjust, then press “Enter“ to store the value.

• 0 - 10,000 ft

(0 ft default)

Outlet Area: Press “Edit“ to change the stack outlet

area. Press “Inc“ or “Dec“ to increase or decrease the

area, respectively. Then press “Enter“ to store the value.

• 0-10 Ft²

Display Brightness: Press “Edit“ to change brightness.

Press “Inc“ or “Dec“ to adjust, then press “Enter“ to

store the value.

• 10 - 100%

(80% default)

Greenheck

Sure-Aire V 2.00

0.0010 CFM

3.96 mA

Setup Up Down Home

Display Setting Options and Setup

WARNING

Due to load resistance change from product to

product, it may be necessary to recalibrate the

4-20mA electronics. See 4-20 mA transducer

calibration procedure.