7

Optional Construction

& Accessories

Inlet Guard

Assembled and mounted low-pressure loss, zinc

coated guards.

Belt Guard

Custom guarding with two tachometer holes and belt

tension inspection door, assembled and mounted.

Protective Cage

Totally enclosed guard to protect personnel from

unhoused spinning wheel. Typically packaged

with a belt guard to provide complete protection.

(arrangement 1 QEP also requires a shaft guard).

Shaft Guard

Formed guard that covers the shaft between the belt

guard and the plenum cage (arrangement 1 only).

Extended Lube Lines

Allows for bearing lubrication from a remote location.

Ideal for guarded fans or for relocating all lubrication

requirements to a single, readily accessible location.

Factory Selected Drives

Cast iron sheaves and matched belts standard

XJUIBESJWFTFSWJDFGBDUPS*OTUBMMFEBOEBMJHOFE

to provide reduced vibration levels and minimize

installation costs.

Motor for use with Frequency Drive

Motors meet EPACT or NEMA Premium efficiencies

BOEBSFBWBJMBCMFJO7'%DPNQBUJCMFDPOTUSVDUJPO

Disconnect Switch

Toggle type and heavy duty disconnect switches are

available for positive electrical shutoff and safety

when servicing fans.

Sure-Aire™ Flow Measurement

Sure-Aire™ provides the real-time flow measurement

for use in building automation systems. The Sure-

"JSFhTOPOJOWBTJWFEFTJHOJTBDDVSBUFUPXJUIJO

and does not impact fan performance.

Isolators

#BTFNPVOUJTPMBUPSTBSFBWBJMBCMFJOFJUIFSOFPQSFOF

or spring mounts. The isolators are sized to match the

fan weight at each mounting point.

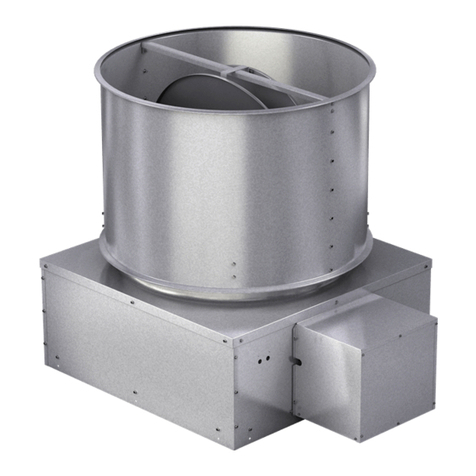

Isolation Base (QEP)

Provides a known space envelope for the complete

fan assembly. Compact C-channel platform welded

for superior rigidity and solid foundation.

Extended Life Bearings (QEP)

Air handling quality, pillow block bearings meet a

basic rating fatigue life L10QFS"#."TUBOEBSET

in excess of 200,000 hours at maximum operating

speed. Equivalent to average or L life of 1,000,000

hours.

Inlet Vane Damper (QEP)

#VJMUJOUPUIFJOMFUDPOFBOEBMMPXTGPSDPOUJOVPVT

modulation of airflow or one-time system balance at

start-up.

Inlet Collar (QEP)

8FMEFEUPUIFGBOJOMFUQBOFMBSSBOHFNFOUPSJOMFU

cone (arrangement 1 and 4) to allow for round slip-fit

connections to the fan inlet.

Inlet Flange (QEP)

Circular inlet flanges with pre-punched holes provide

an easy means for bolted connection to ductwork.

Requires an inlet collar. Matching bolt-on companion

flanges are also available.

Special Coatings (QEP)

Special coatings are available for protective purposes.

Coatings are applied before assembly so that each

manufactured component is coated inside and out.

Consult Greenheck’s Product Application Guide,

1FSGPSNBODF$PBUJOHTGPS7FOUJMBUJPO1SPEVDUTGPSB

complete listing of coatings and a relative resistance

chart.

QEM QEP

#FBSJOHT&YUFOEFE-JGF

L10 IST- 1,000,000 hrs /" Optional

Isolation

Direct Mount Isolators Optional Optional

4USVDUVSBM#BTFX*TPMBUPST /" Optional

OSHA Compliant Guarding

Guard, Inlet Optional Optional

(VBSE#FMU Optional

Guard

Package

Optional

Guard, Shaft Optional

Protective Cage Optional

Extended Lube Lines Optional Optional

Sure-Aire™ Flow Monitor Optional Optional

*OMFU7BOF%BNQFS/FTUFE /" Optional

Inlet Collar /" Optional

Flange, Inlet /" Optional

Special Powder Coatings /" Optional