COMMUNICATIONS PROTOCOL 3

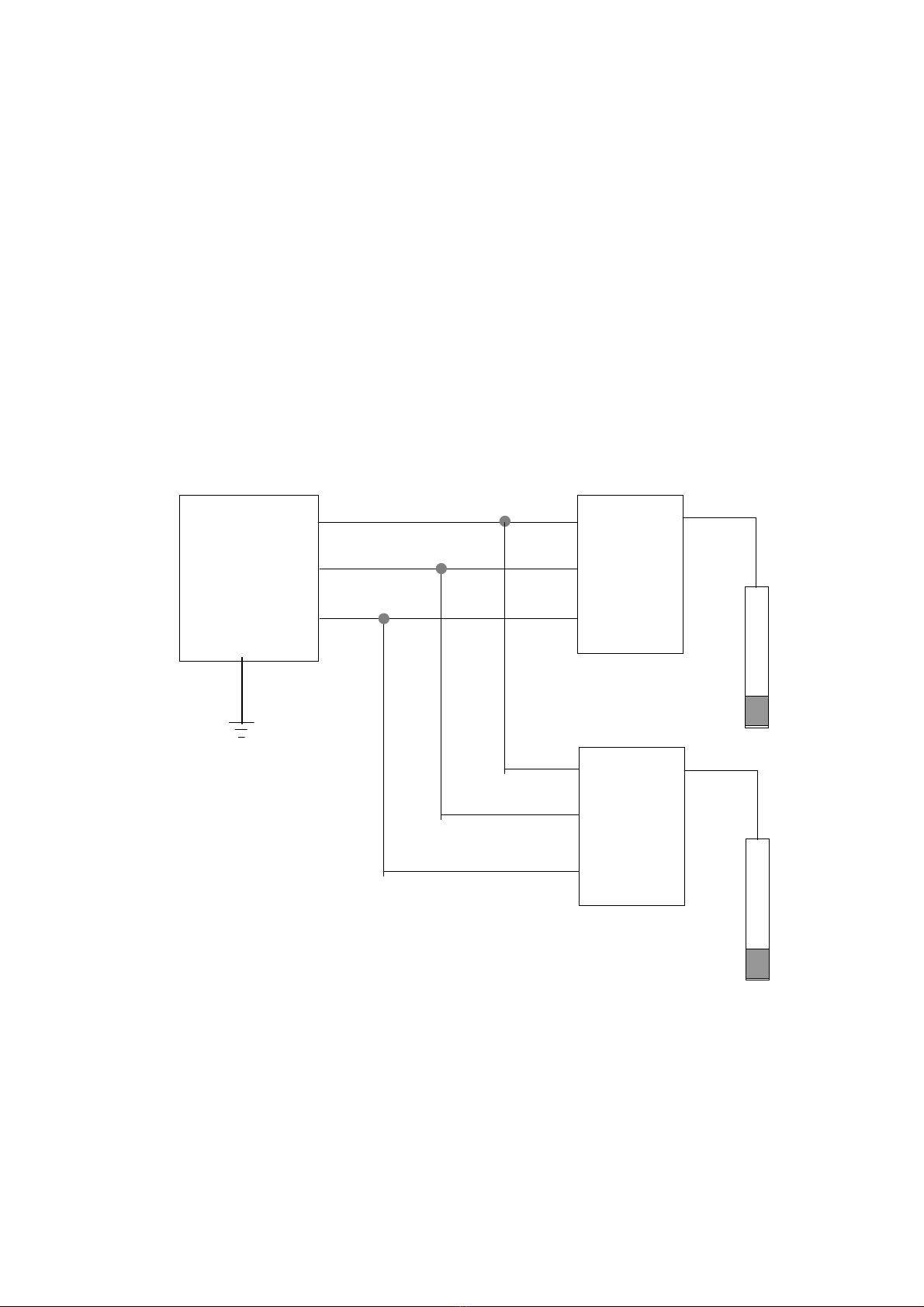

SDI-12 Control Sequence

SDI-12 data loggers and sensors communicate by an exchange of ASCII

characters on the serial data line. The data logger sends a break to wake up the

sensors on the data line. A break is a continuous spacing on the data line for at

least 12 milliseconds. The data logger then sends a command. The sensor, in

turn, returns the appropriate response. Each command is for a specific sensor.

The first character of each command is a unique sensor address that specifies

which sensor the logger wants to communicate with. Other sensors on the SDI-

12 bus ignore the command and return to low-power standby mode. When a

data logger commands a sensor to start its measurement procedure, the logger

does not communicate with any other sensor until the data collection from the

first sensor is complete.

A typical recorder/sensor measurement sequence proceeds as follows:

Step 1. The data logger wakes all sensors on the SDI-12 bus with a break.

Step 2. The logger transmits a command to a specific, addressed sensor,

instructing it to make a measurement.

Step 3. The addressed sensor responds within 15 milliseconds and

returns the following information:

a) The maximum time before the measurement data is ready.

b) The number of data values it will return.

Step 4. If the measurement is immediately available, the logger transmits

a command to the sensor instructing it to return the

measurement(s). If the measurement is not ready, the data logger

waits for the sensor to send a request to the logger, to indicate

that it is ready. The logger then transmits a command to get the

data.

Step 5. The sensor responds, returning one or more measurements.

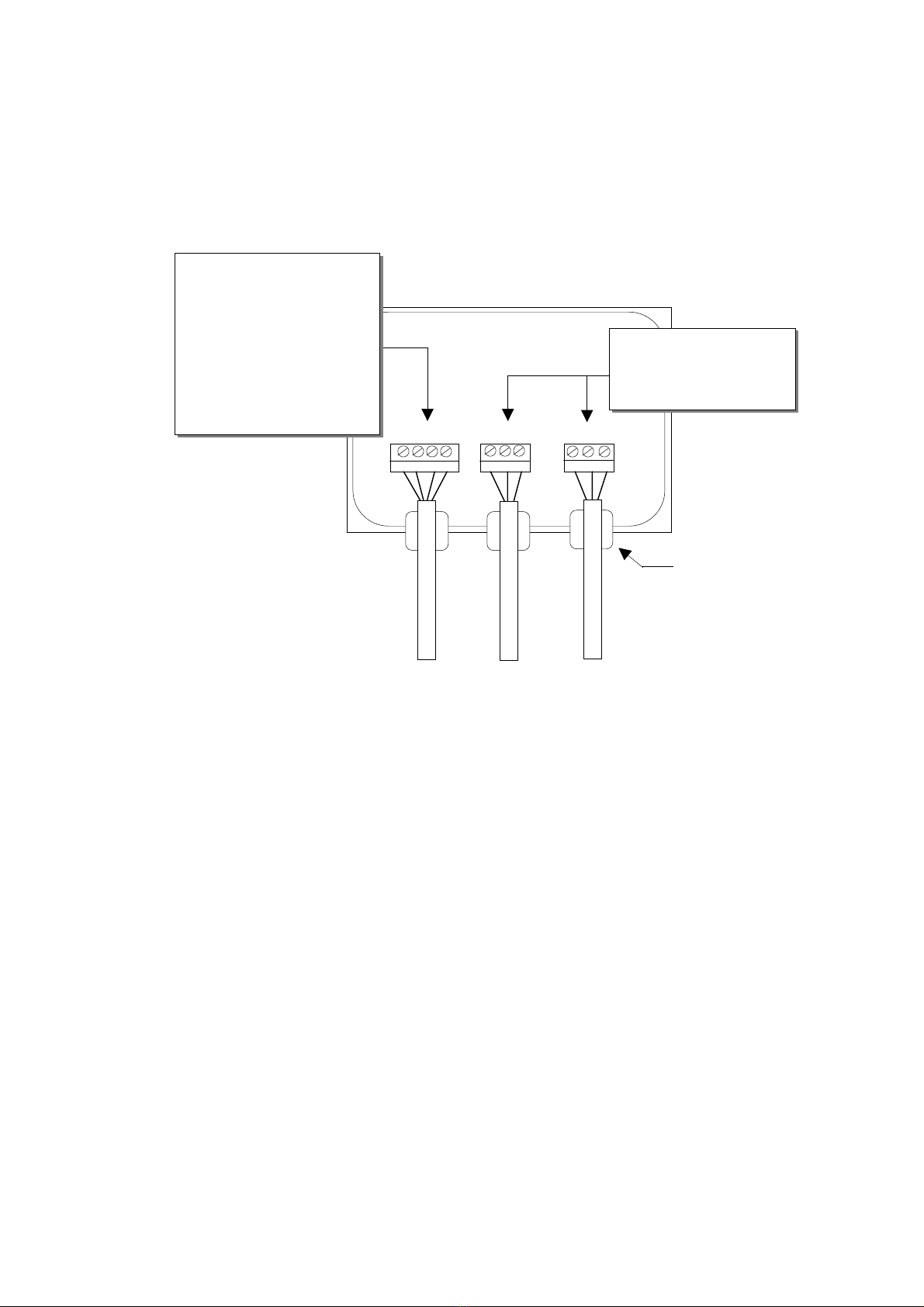

There is a maximum of nine addresses that can be accessed on the network and

these are numbered 00 to 09.

Note that it is possible to setup for dual logging if the sensor type is a

Greenspan Smart sensor with onboard logger. The SDI-12 data logger can

request readings at any time from the Smart sensor independently of the

readings being logged by the sensor.

UM-010-0012-SDI-12 GREENSPAN TECHNOLOGY 4