7

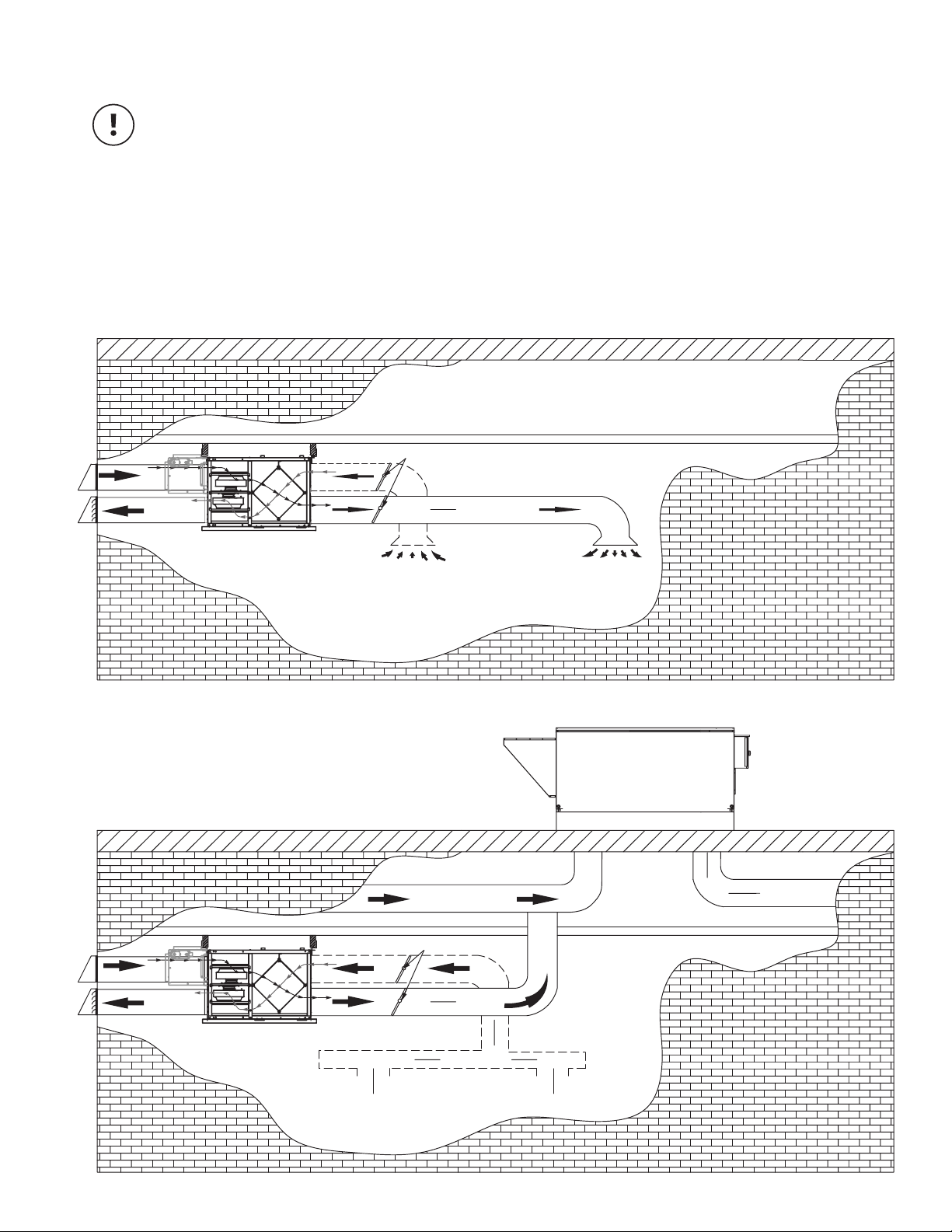

Exhaust air ducting

The stale air exhaust system is used to draw air from the points in the building where the worst air quality problems occur. ( See installation

examples in the manual.)

Installing ducts to / from inside

Direct connection to furnace/ air handler return duct

• Should you wish to hard duct the supply air directly into the cold air return of the HVAC systems, remember to check the airflow balance of the HRV

with the HVAC systems fan both “on”and “off” to determine that it does not imbalance the HRV more than 10%. Make sure you respect the minimum

distance from the supply air in of the HRV and the HVAC systems.

• It may be necessary to install a separate fresh air supply ductwork system if the heating is other than forced air.

When installing an HRV, the designer and installer should be aware of local codes that may require smoke detectors and/or firestats in the HVAC

or HRV ductwork.

Because an HRV is designed to bring fresh air into the building, structures may require supply voltage interrupt when smoke or flame sensors are

triggered, or when a central fire alarm system is activated.

To maximize airflow in the ductwork system, all ducts should be kept short and have as few bends or elbows as possible. Forty-five degree are

preferred to 90elbows. Use “Y” tees instead of 90elbows whenever possible.

All duct joints must be fastened with screws or duct sealant and wrapped with a quality duct tape to prevent leakage. Aluminum foil duct tape is

recommended.

Supply air ducting

In buildings without a forced air HVAC systems, fresh air should be supplied to all habitable areas. It should be supplied from high wall or ceiling

locations. Grilles that diffuse the air comfortably such as grille {MGE (metal) }grilles with "coanda effect" are recommended.

Optional inline duct heaters may be used to add heat if required.

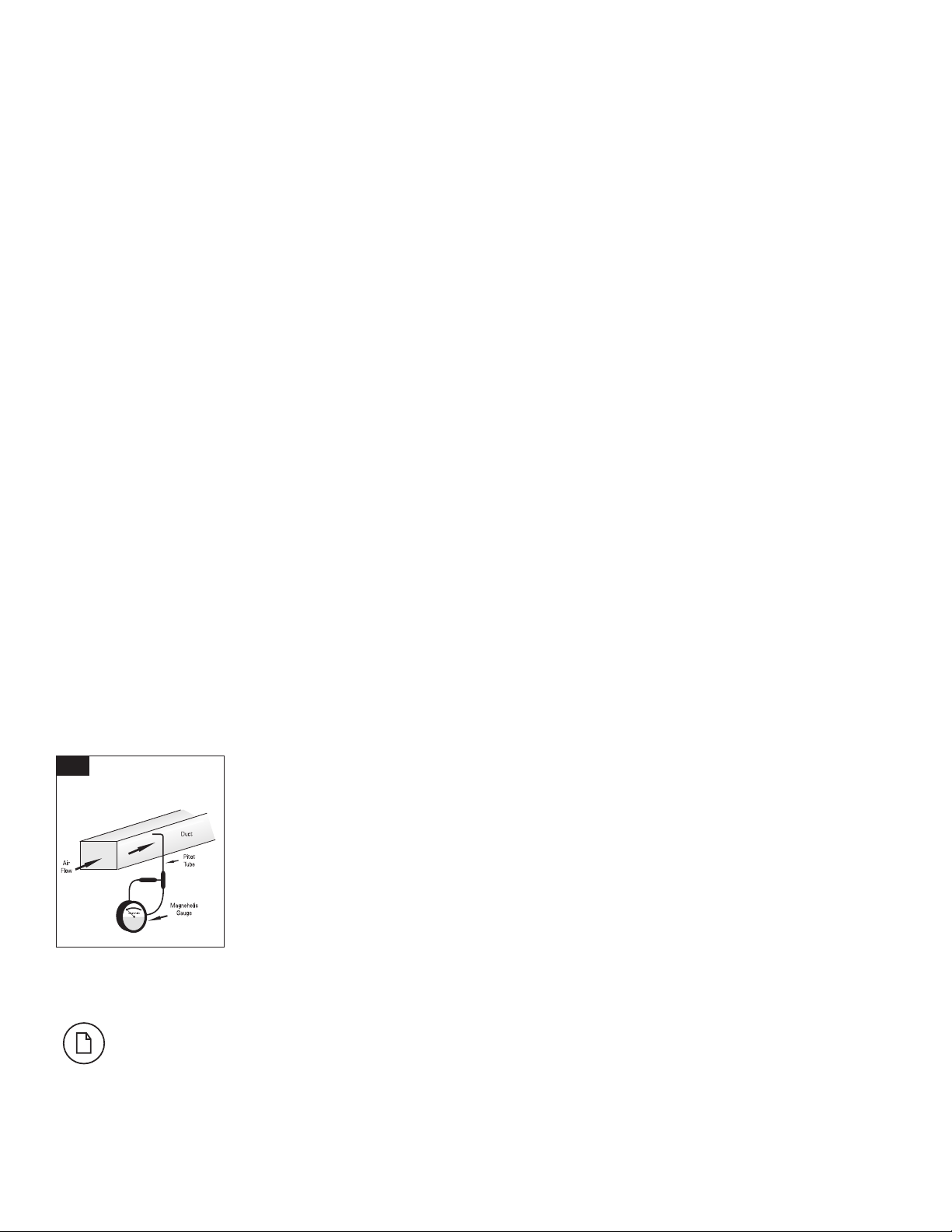

AThe duct’s airflow velocity

is generally measured

with a magnehelic gauge

and a pitot tube.

• To avoid airflow turbulence

and incorrect readings, the

airflow velocity should be

measured on steel ducting

a minimum of 3 duct

cross-sections from the

unit or elbow and before

any transition.

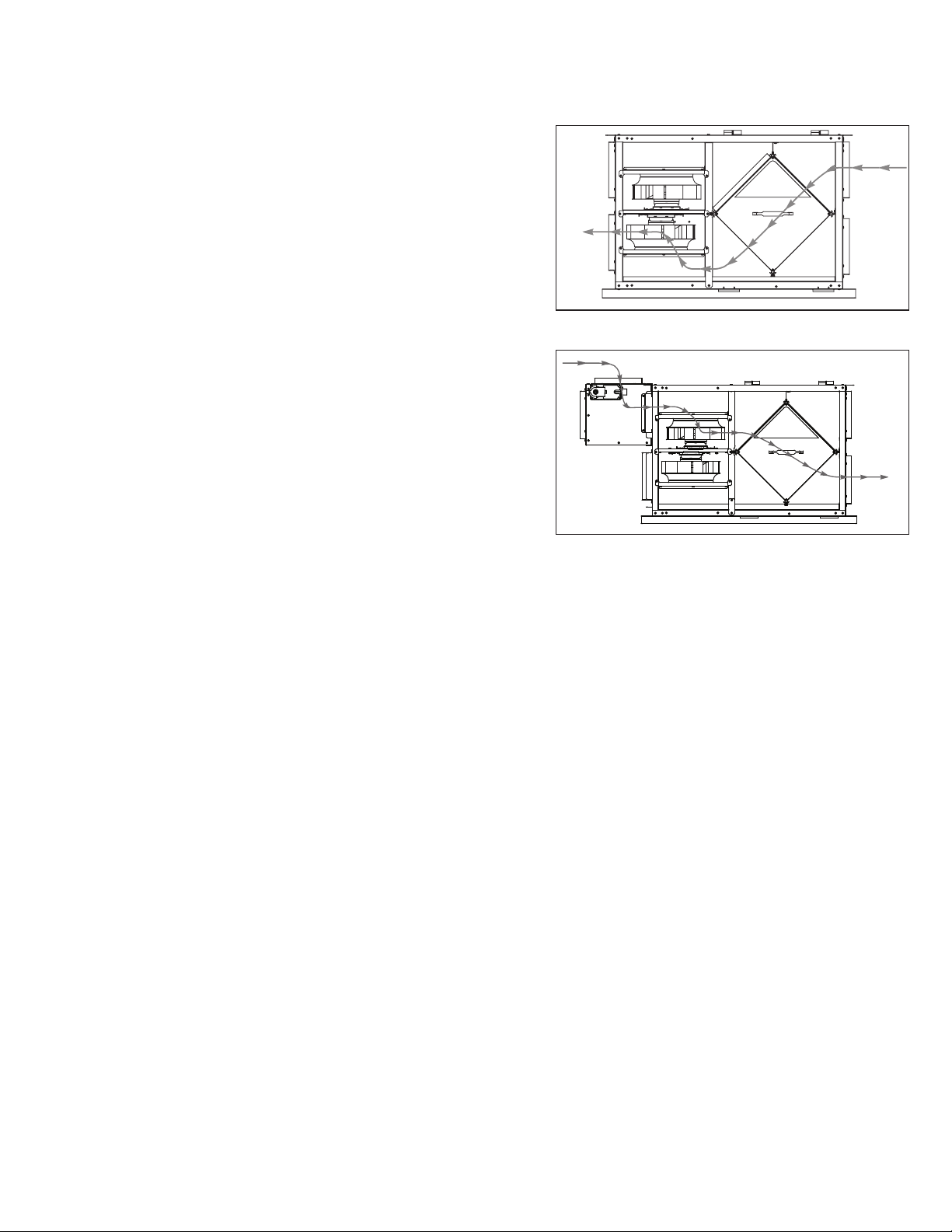

• The balancing procedure consists of measuring the exhaust air leaving the system and the supply air entering the system and ensuring that these

two are equal. A deviation of 10% or less is acceptable.

Airflow balancing

A*

Pitot tube and gauge

A professional air balancer should be contacted to commission the system properly. A skilled HVAC Tech may complete the balance

of air providing they possess the proper equipment. Call Greentek Technical support for assistance.