Carbon Monoxide Transmitter Installation Manual

IN-CMD5B1-01-01 May 2, 2017 Page 5

Common Specifications

Measurement . . . . . . . . . . . . . . . . . Electrochemical

Sample Method . . . . . . . . . . . . . . . Diffusion

Measurement Range . . . . . . . . . . . 0-300 ppm

Accuracy . . . . . . . . . . . . . . . . . . . . 5 ppm or 5% of reading (whichever is greater)

0-50 C (32-122 F), 15-90 %RH

Agency Approvals . . . . . . . . . . . . Sensor is UL Recognized for ANSI/UL-2034 and UL-2075, E240671

Operating Conditions . . . . . . . . . . -20-50 C (-4 -122 F), 15-90 %RH, 0.9-1.1 atm

Stability . . . . . . . . . . . . . . . . . . . . . < 5% signal loss/year

Response Time . . . . . . . . . . . . . . . < 35 seconds for 90 % step change

Typical Area Coverage . . . . . . . . . 700 m2(7500 ft2) or 15 m (50 ft) radius

Wiring Connections . . . . . . . . . . . Screw terminal block (14 to 22 AWG)

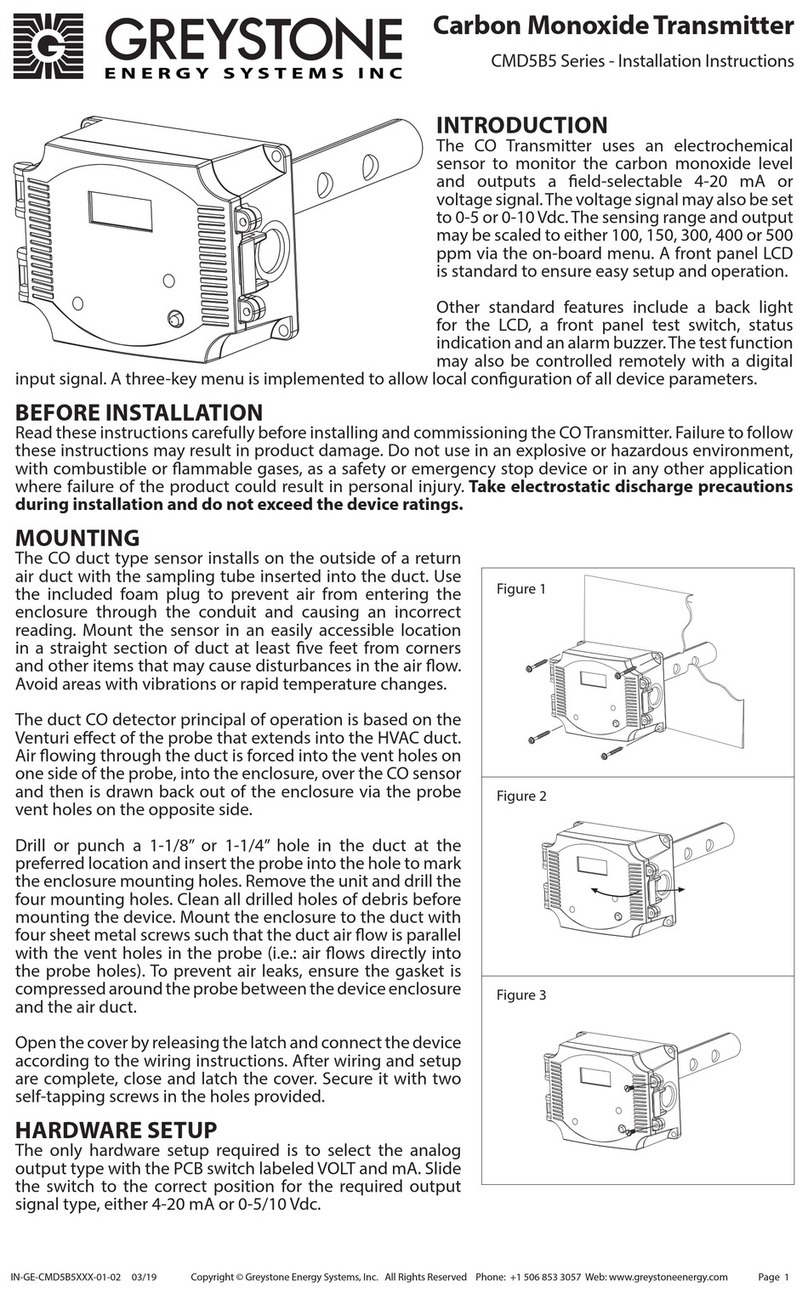

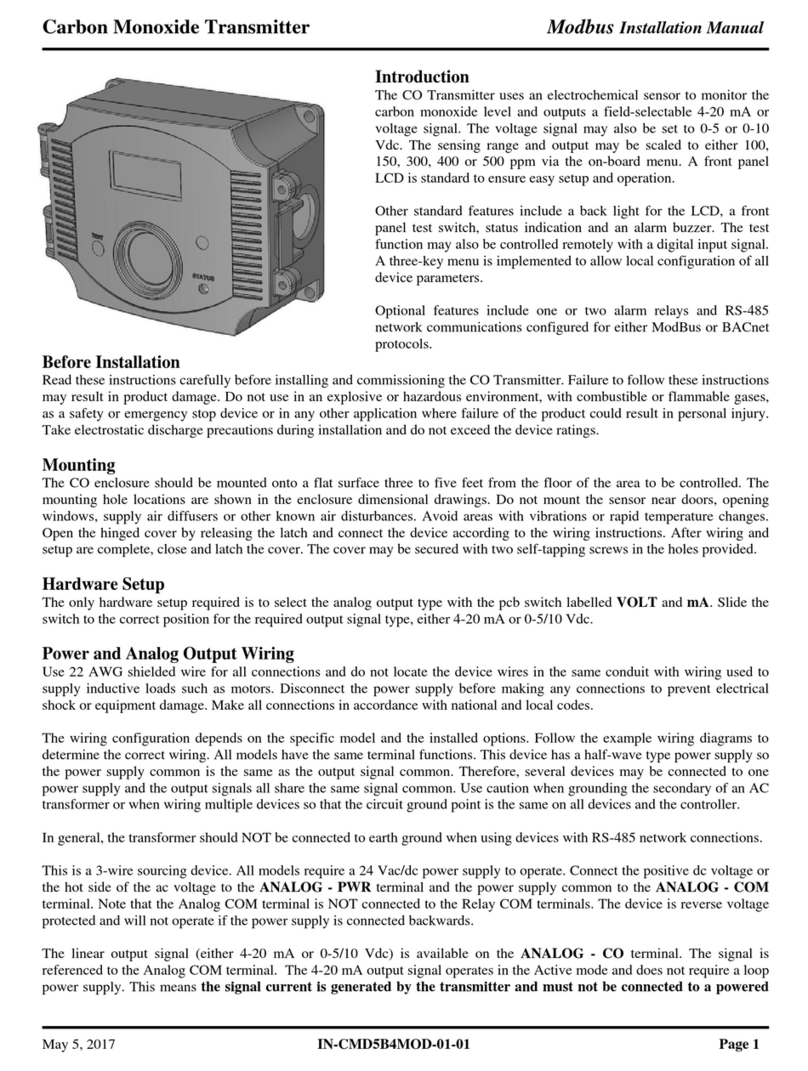

Enclosure . . . . . . . . . . . . . . . . . . . 2.8”w x 4.1”h x 1.9”d (71 x 104 x 48 mm)

2-Wire Loop-Powered Model

Power Supply . . . . . . . . . . . . . . . . 24 Vdc ± 20% or 24 Vac ± 10% (non-isolated half-wave rectified)

Consumption . . . . . . . . . . . . . . . . . 20 mA max

Output Signal . . . . . . . . . . . . . . . . 4-20 mA loop-powered

Output Drive Capability . . . . . . . . 550 ohms max @ 24 Vac/dc

3-Wire Relay Model

Power Supply . . . . . . . . . . . . . . . . 24 Vdc ± 20% or 24 Vac ± 10% (non-isolated half-wave rectified)

Consumption . . . . . . . . . . . . . . . . . 50 mA max

Output Signal . . . . . . . . . . . . . . . . 4-20 mA sourcing

Output Drive Capability . . . . . . . . 550 ohms max @ 24 Vac/dc

Relay Contacts . . . . . . . . . . . . . . . Form C contacts (N.O. and N.C.), 5 Amps @ 250 Vac, 5 Amps @ 30 Vdc

Relay Trip Point . . . . . . . . . . . . . . 25, 60 or 150 ppm jumper selectable

Relay Hysteresis . . . . . . . . . . . . . . 3% or 9 ppm