Phaserunner Controller User Manual

Rev 2.0

3 Installation and Mounting

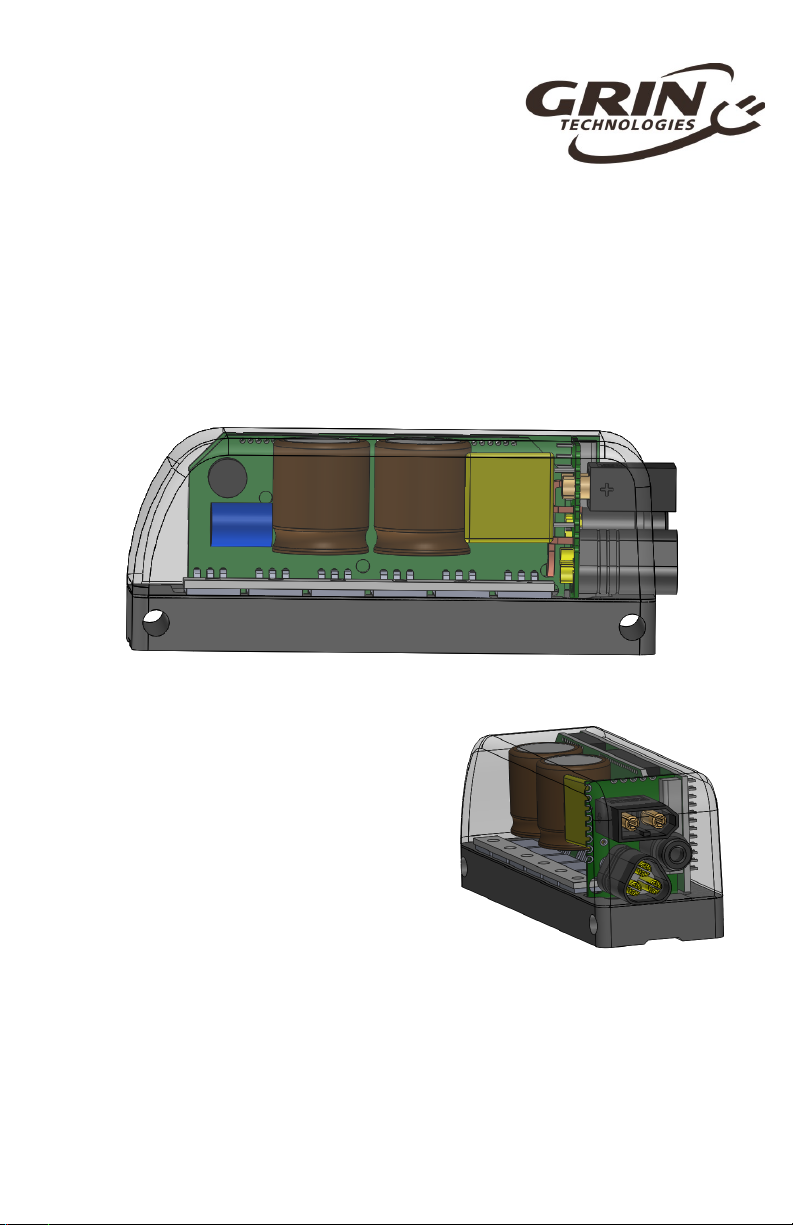

The Phaserunner is esigne to be narrow in

wi th an has a channel own the back of the

heatsink so that it can be strappe to your bicycle

tubing with a pair of cable ties. When mounte

externally like this, the controller is expose to

abun ant air flow for cooling an the on-off button

remains accessible.

If you want to install the controller insi e a vehicle

chassis, then the aluminum heatsink shoul be

bolte irectly to a metal plate via the 4 mounting

holes in or er to help with heat issipation.

Otherwise it will be more prone to overheating

an going into thermal rollback at high currents.

If the controller running at full 96A an is mounte to a bike tube expose to

airflow, it will hit thermal rollback after 1-2 minute an then settle to ~50 amps of

stea y state phase current. When bolte to a large external heatsink, the thermal

rollback at full current will take longer to kick in (4-6 minutes) an will level off at

aroun 70 amps of phase current.

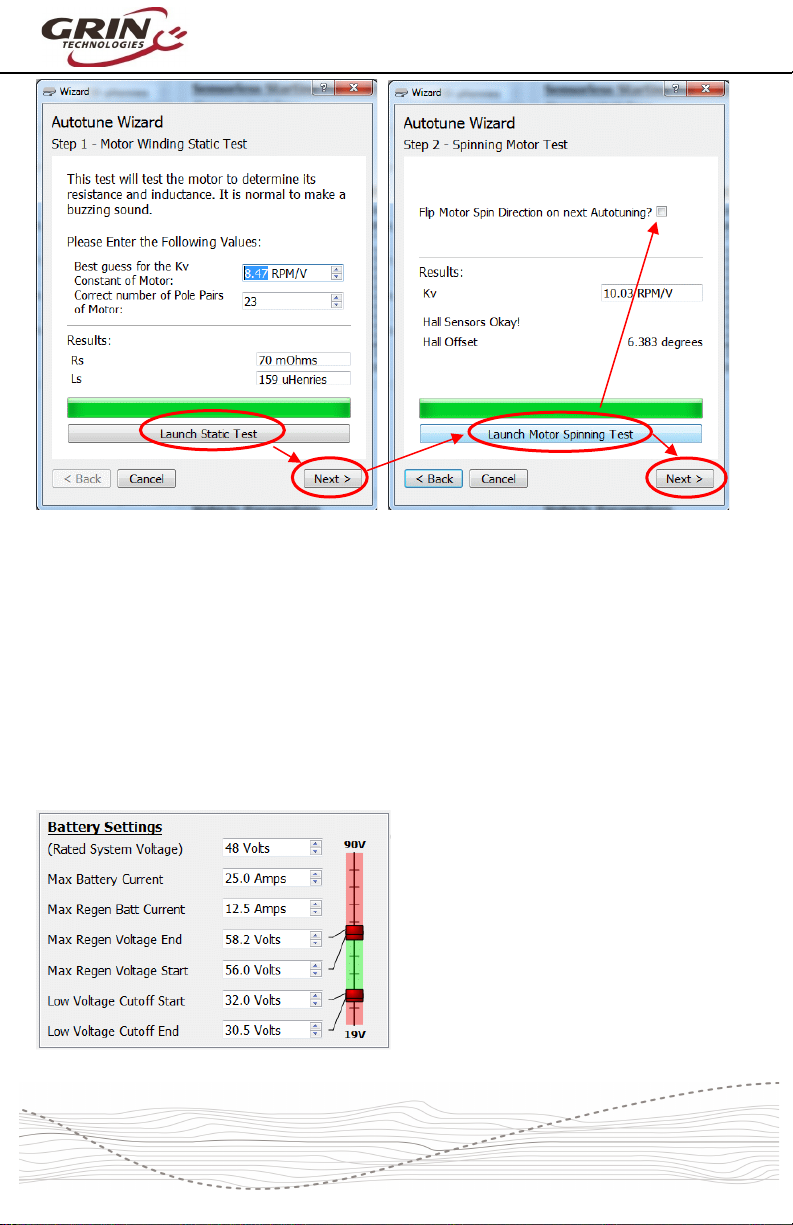

4 Parameter Tuning

If you purchase the Phaserunner as part of a complete kit package with a

motor, battery etc. then most likely the ven or will have alrea y preconfigure the

controller parameters so you can just plug things in an go.

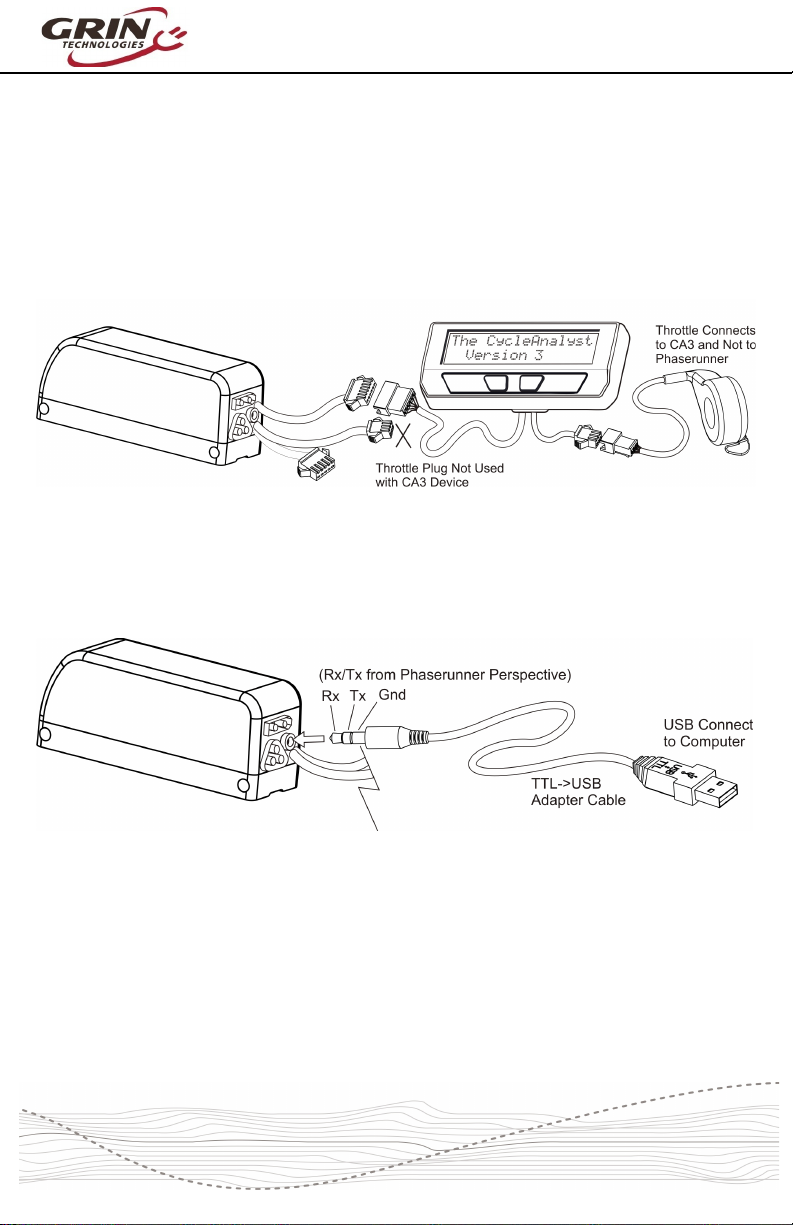

Otherwise, for your first run you will want to have the Phaserunner plugge into

your battery pack an motor, with a computer or laptop nearby that has the

Phaserunner software installe .

The Phaserunner software is available for Linux, Win ows, an MacOS from our

webpage:

http://www.ebikes.ca/pro uct-info/phaserunner.html

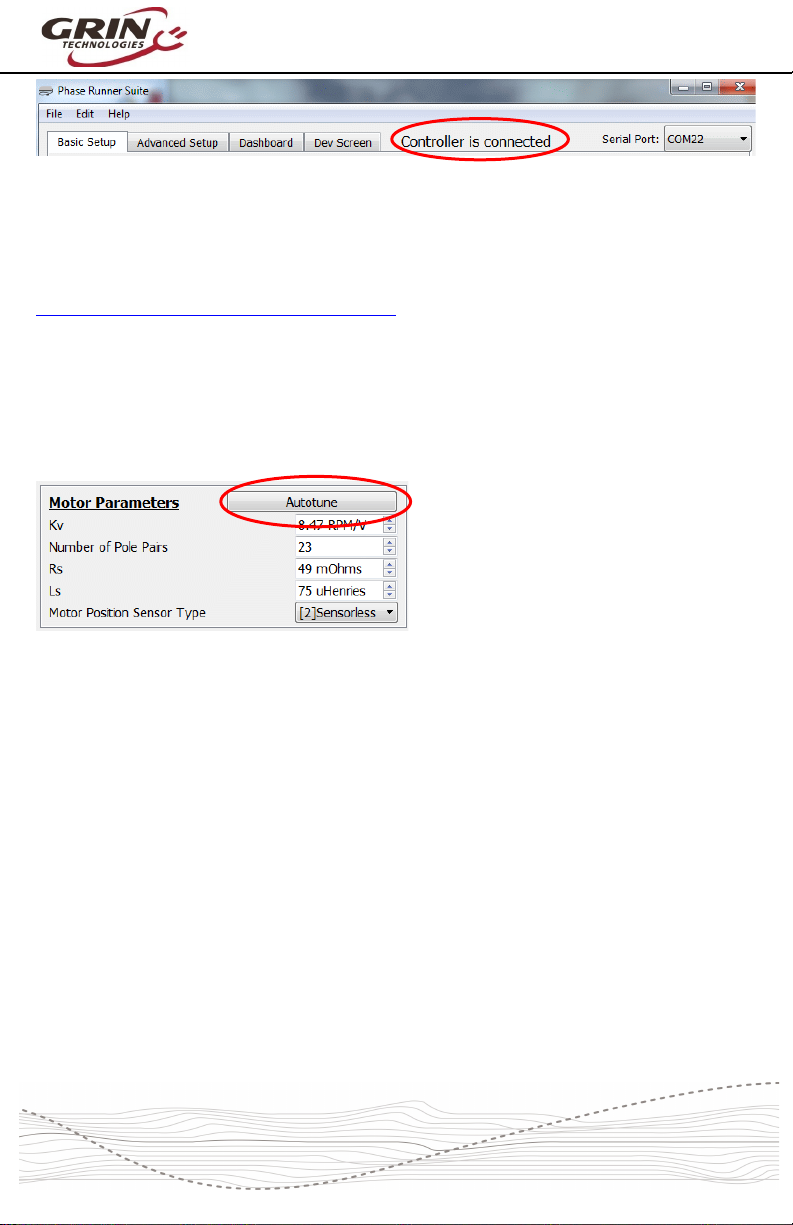

Plug in the TTL->USB cable to link your computer to the Phaserunner, with the

Phaserunner turne on. When you launch the Phaserunner software, the status

isplaye on the top bar shoul then say “Controller is connecte ”.