Cycle Analyst V3.1 User Manual

Rev 1.0

charge, during use, and hen the battery goes flat. This is often your first clue to

anomalous behavior and provides very useful troubleshooting information.

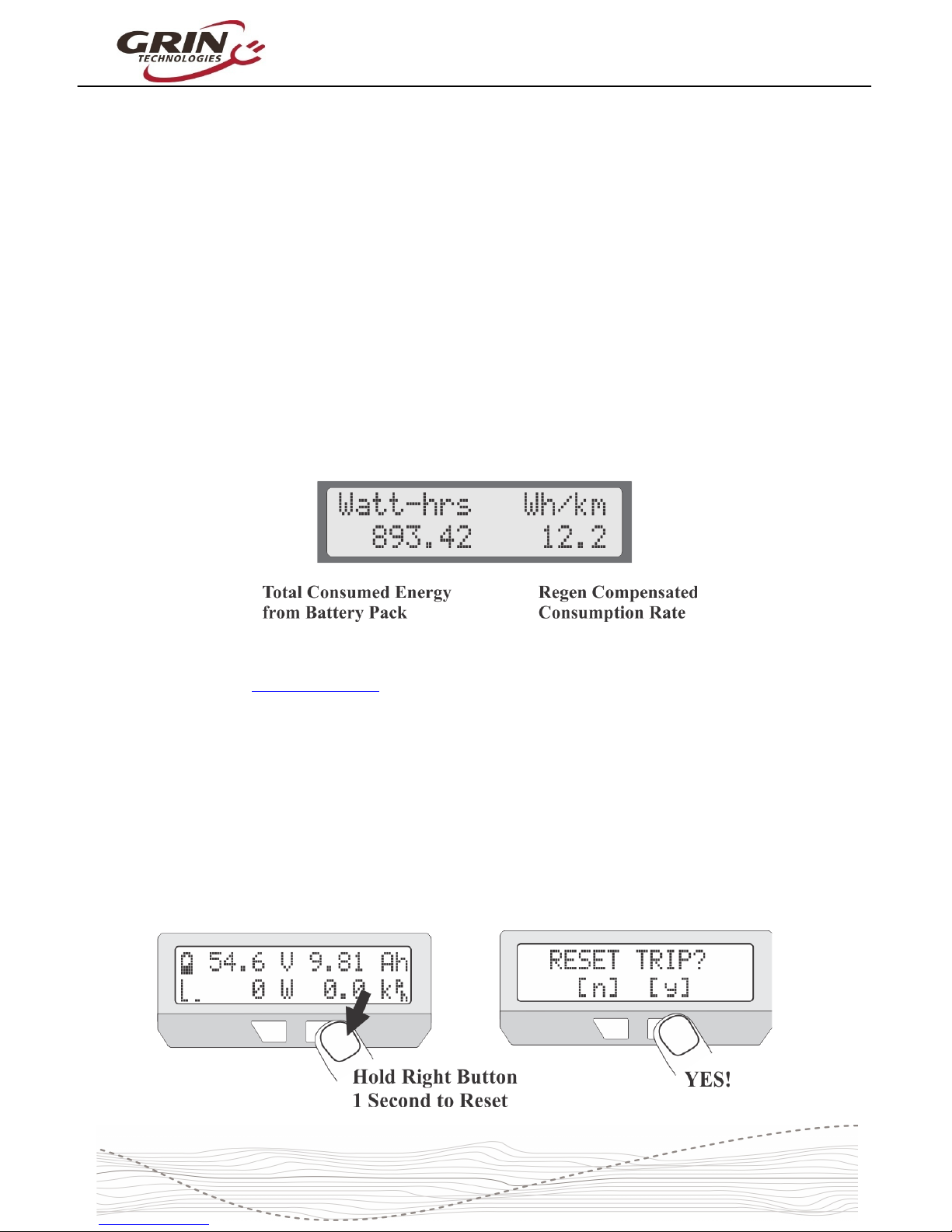

The top right is a customizable display field. By default, this toggles bet een

sho ing your accumulated amp-hours and distance since the last trip reset, but it

can be configured to sho other things like motor temperature, instantaneous

h/km, pedal cadence and so forth. You ill eventually find the consumed amp-

hours to be among the most useful and important pieces of information on the

CA display, but only if you remember to do a trip reset each time there is a fresh

charge on the battery pack.

The bottom left of the display has a throttle position that moves up and do n ith

the user's throttle signal going into the Cycle Analyst. This is replaced by an

animated brake lever if the ebrake cutoffs are engaged. Just beside this slider is

an animated Pedal Assist bar graph, hich is only active if you have a PAS

sensor and visually indicates ho fast or hard you are pedaling.

The bottom left numeric display by default sho s the electrical po er currently

flo ing through the system, and ill go negative during regenerative braking. It

is possible to change this to display amps instead of atts if you prefer.

Finally, on the bottom right is a readout of your current vehicle speed, in either

kph or mph as chosen in the setup menu.

The left and right buttons ill scroll through other display screens that sho

specific information that may be of interest. These screens are explained in detail

on the CA3 eb page and any of them can be hidden from vie if desired. The

diagnostics screen and att-hour screen are of particular interest though.

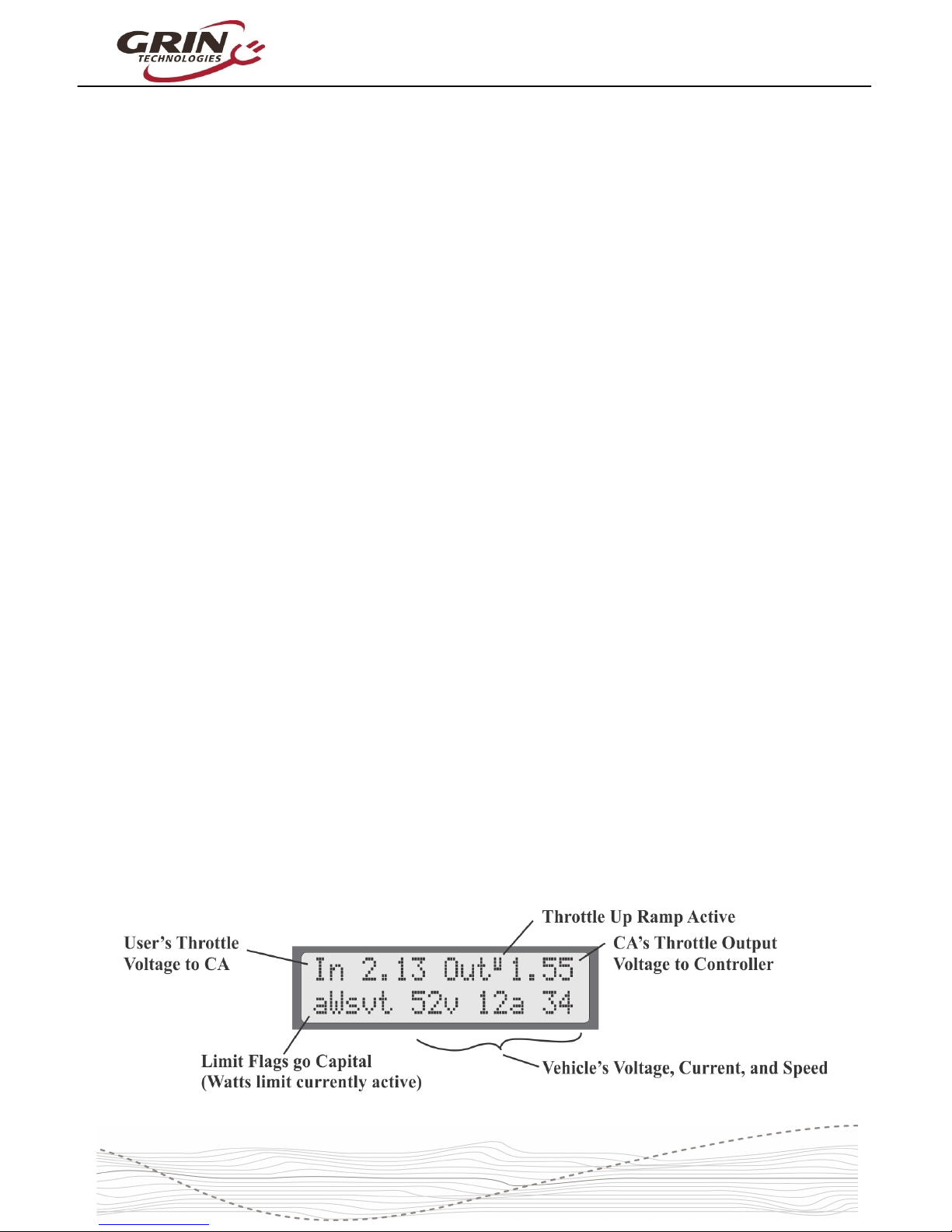

4.2 Diagnostics Screen, Display 12

If you press the left button once from the main display, you ill have the

diagnostics display. This can be invaluable during any kind of system

troubleshooting. The top line sho s the actual throttle voltage signal going into

the CA3, as ell as the throttle voltage going out to your motor controller. If the

rate of change of the throttle is being clamped, then the associated rate limit ill

sho up (F = fast, U = up, P = PAS, D = do n, see section 6.5).

8