6– English

MAINTENANCE

Bandsaw Blade

WARNING!

The bandsaw blade is sharp and

can cause cuts. Warning for

personal injury. Wear protective

gloves whenever you handle the

bandsaw blade.

The bandsaw blade should be set and sharp-

ened regularly to give optimal performance.

During normal sawing of most species of wood

this should be done at intervals of approx. 2

hours of effective cutting time. Effective cutting

time only refers to the time that the bandsaw

blade actually works. The bandsaw blade should

be sharpened more frequently when cutting

those species of wood with a high sand content.

Dismantling

Dismantle the bandsaw blade as follows:

1. Remove the guards over the band wheels.

2. Loosen the right-hand band wheel by crank-

ing about 10 turns anticlockwise.

3. Carefully remove the bandsaw blade.

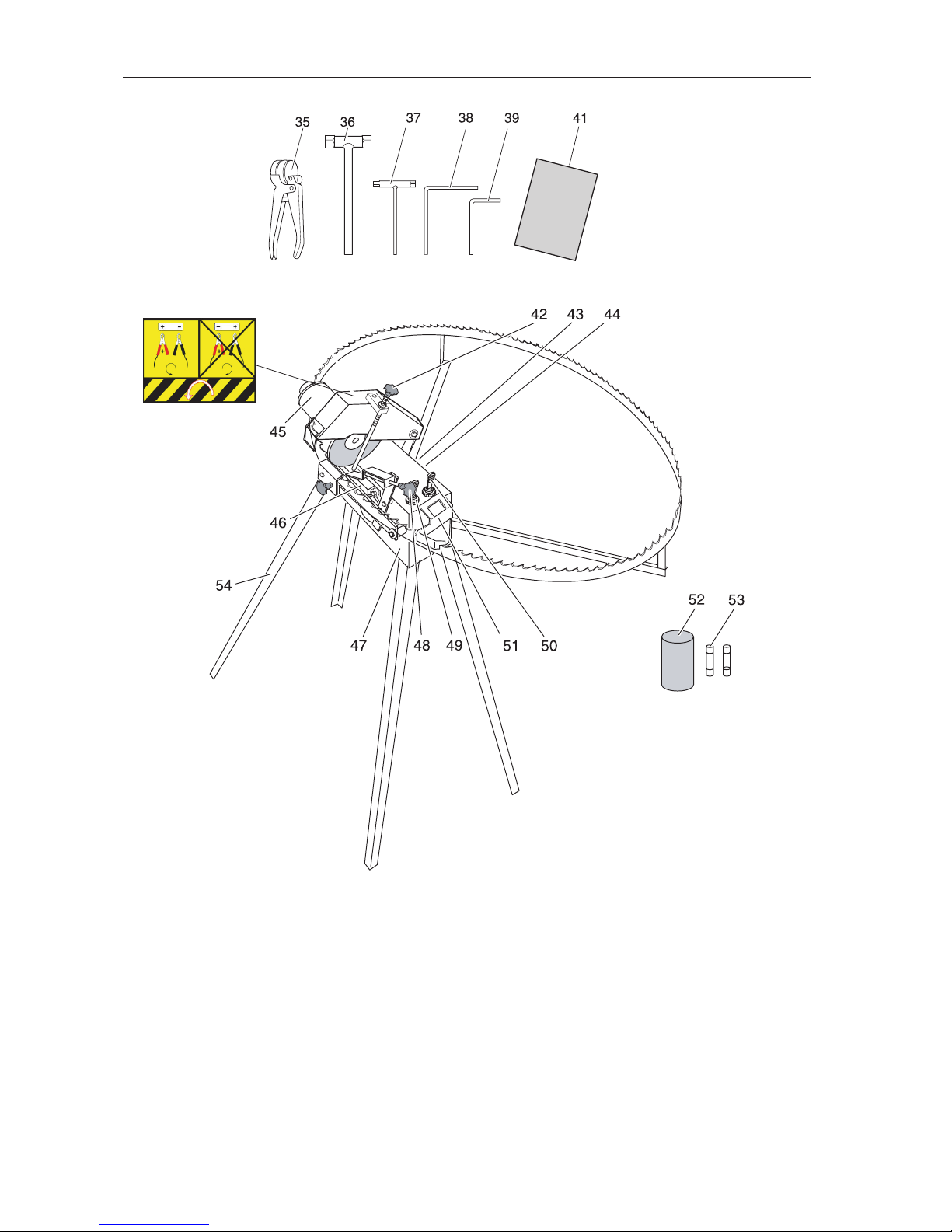

Cleaning and Inspection

Clean sawdust and any coating from the bandsaw

blade. Now check whether there are any cracks

(A) in the gullets. Small cracks can be ground

away when sharpening the bandsaw blade. If the

cracks are so large that they cannot be ground

away, the bandsaw blade should be discarded.

Cracks in the gullets are the most common cause

of bandsaw blade breakage. The bandsaw blade

can be ground to a minimum width of 24 mm. See

FIG. 76. A new bandsaw blade is 32 mm wide.

The bandsaw blade should be discarded once

any part of it reaches the minimum width.

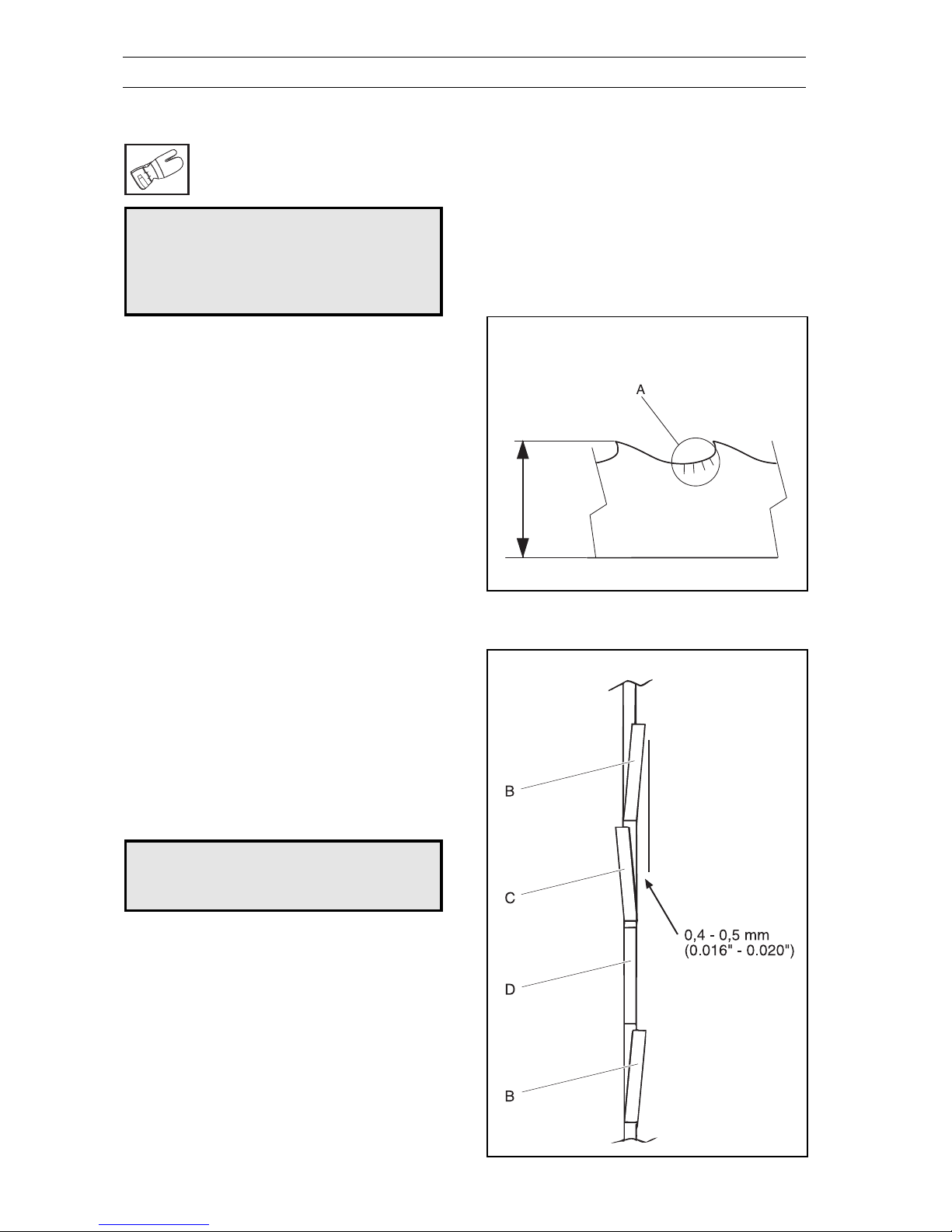

Setting the Saw

The bandsaw blade’s teeth should be set to the

dimensions shown in the adjoining figure. Every

third tooth should remain unset. The teeth should

be set as follows:

B=Set to the right, 0.4-0.5 mm.

C=Set to the left, 0.4-0.5 mm

D=Not set.

The more accurate the set is made, the straighter

and smoother the bandsaw blade runs when

cutting the log. The bandsaw blade should be set,

at a minimum, after every third sharpening.

WARNING!

Never use a damaged bandsaw

blade.

min. 24 mm

!

!

FIG. 77

FIG. 76