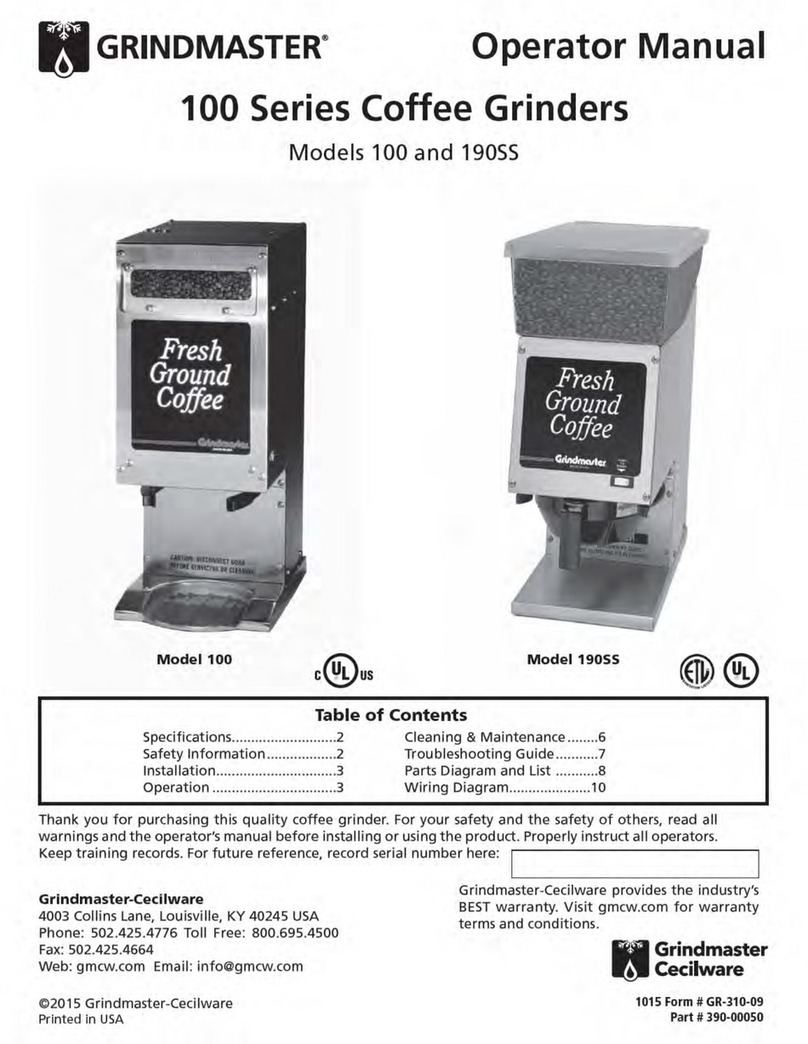

Your new coffee grinder is easy to operate and

maintain. Before you place it in service, please have all

personnel familiarize themselves with these

instructions. Keep this manual in a convenient place for

ready reference.

How to Operate

1. Turn the selector knob to the desired grind

setting.

2. Fill the hopper with the desired type and

amount of whole bean coffee. Close the

lid.

3. Place the bag underneath the spout.

4. Press the start button. *810 model - Press

the grinder switch to the ON position.

5. The grinder will automatically stop when

the bag is removed.**

* 810 model - Once coffee is ground, press

the grinder switch to the off position or

grinder will continuously run.

** On models 835 and 875 the stop button

may be pressed after the grinder has

completed grinding.

6. Remove bag from coffee spout once coffee

is ground.

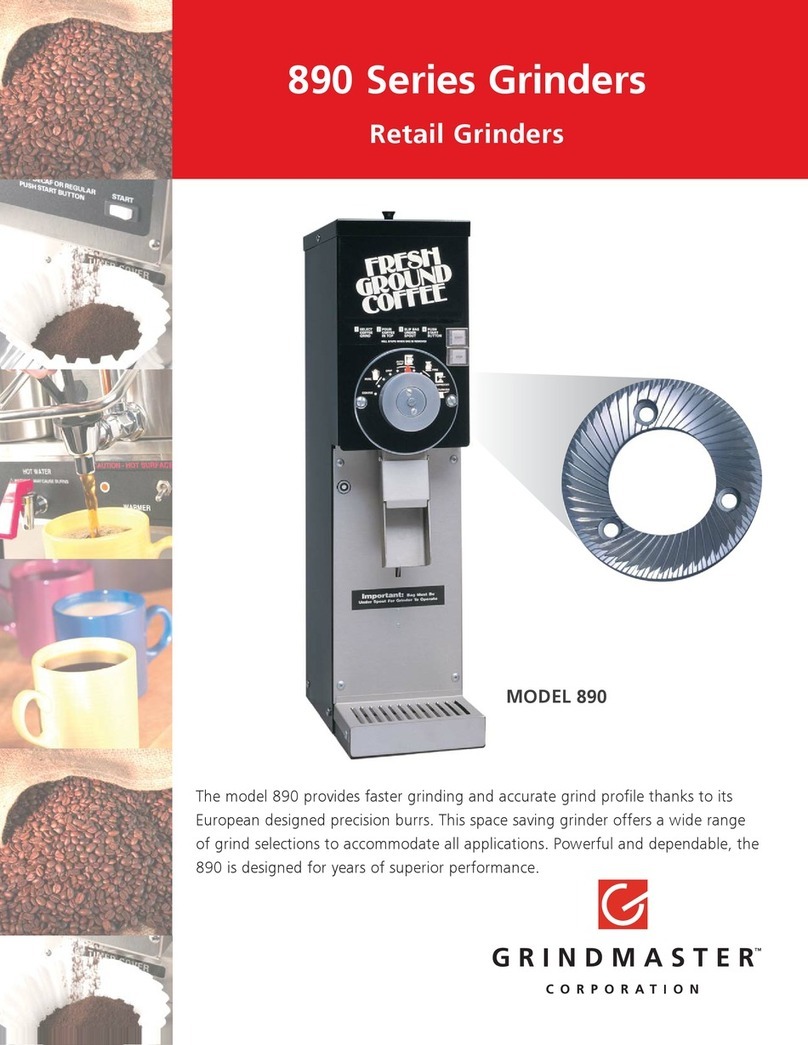

Grinds

Before shipment, this grinder has been tested with

coffee and has been accurately adjusted to deliver

ground coffee to normal auto drip specifications.

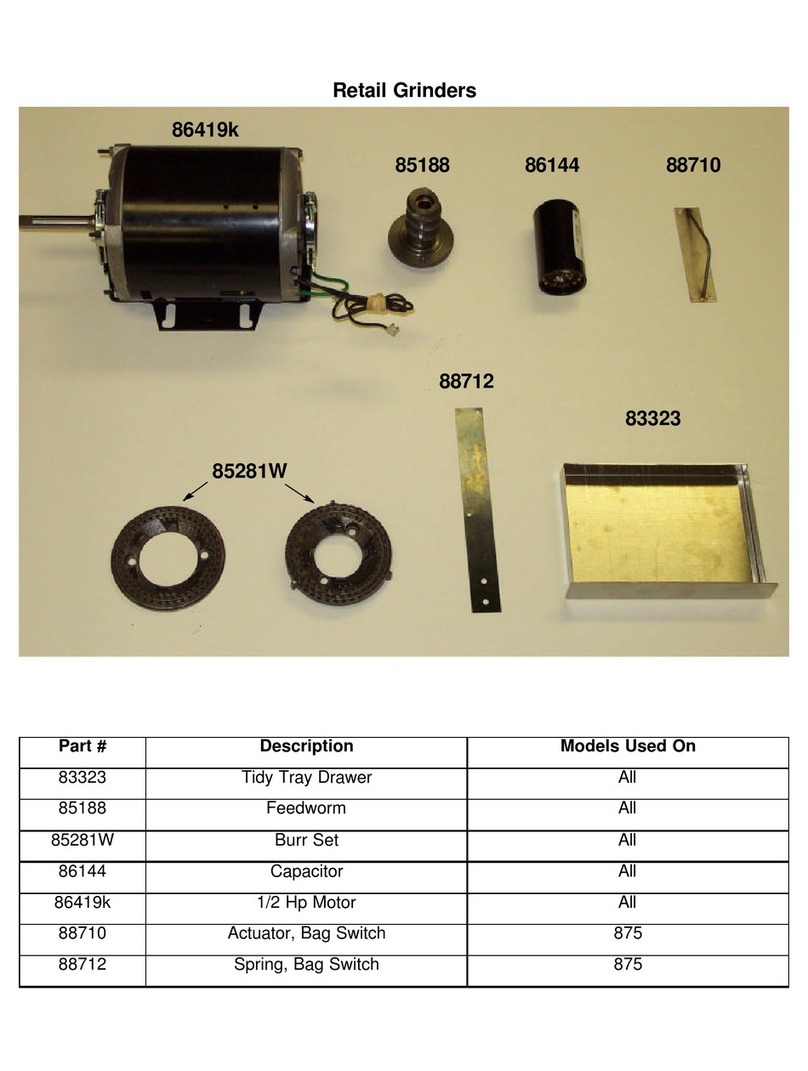

The Grinding Burrs are made of an extremely hard and

wear resistant material. From time to time, grind

adjustments (see following instructions) may be

necessary. If the grind runs coarser than expected after

normal adjustment and the grind time has increased,

the burrs may have excess wear and should be

replaced. New burrs should always be installed as a

pair, never one or the other, as they are accurately

ground and lapped in pairs. Old burrs cannot be

resharpened.

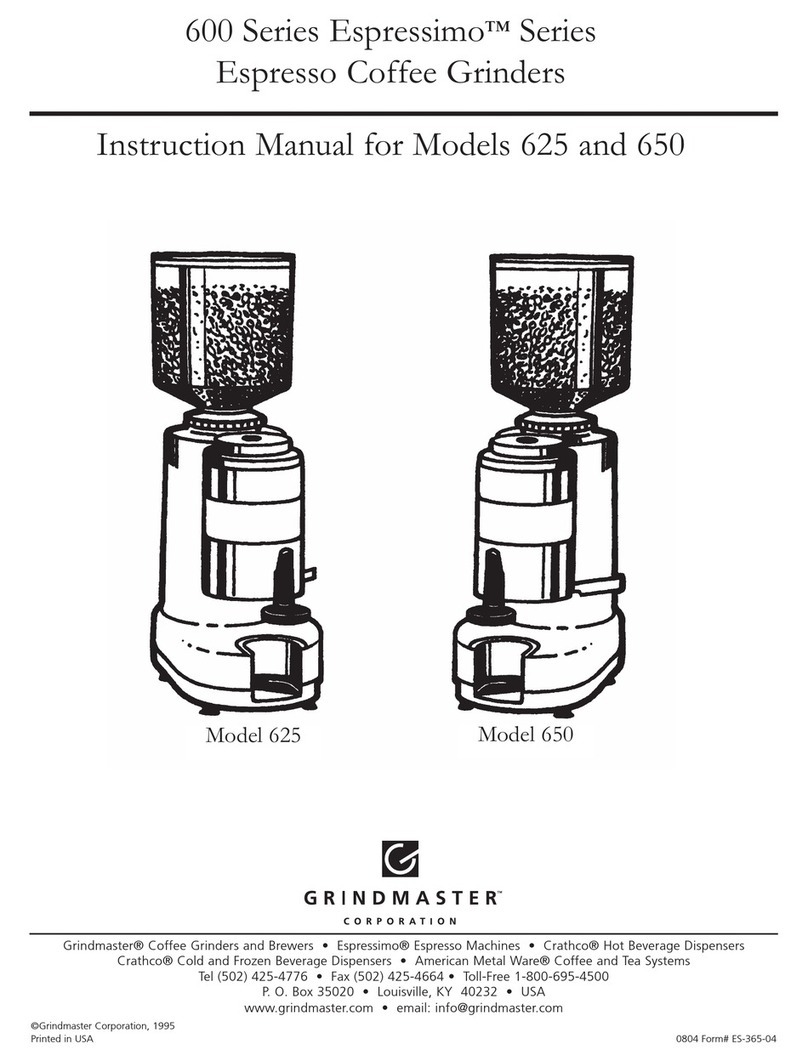

Grind Adjustment

Tools required: Phillips screwdriver

Large blade screwdriver

Pliers

1. Remove all coffee from the hopper.

2. Set selector knob to the finest setting

(Espresso or Turkish) depending on the

model.

3. Loosen both knob retainer screws in

selector knob one turn only.

4. While pressing the bag switch, located

behind the spout, press the start button so

that the grinder will run during

adjustment.

*810 model - Press the on or start button

so that the grinder will run during

adjustment.

5. With the grinder still running, turn the

adjusting screw in the center of the selector

knob slowly to the right until a slight

chirping noise is heard. Immediately turn

the adjusting screw to the left until

chirping noise stops. This is the finest grind

obtainable.

6. Tighten both of the knob retainer screws.

Once the finest grind has been set, the

other grind settings will automatically set

correctly.

7. Press the stop or off button.

NOTICE: Always be sure the grinding burrs are not

touching while the machine is running on the

ESPRESSO/TURKISH setting. Otherwise serious damage

to the motor may result.

Protection

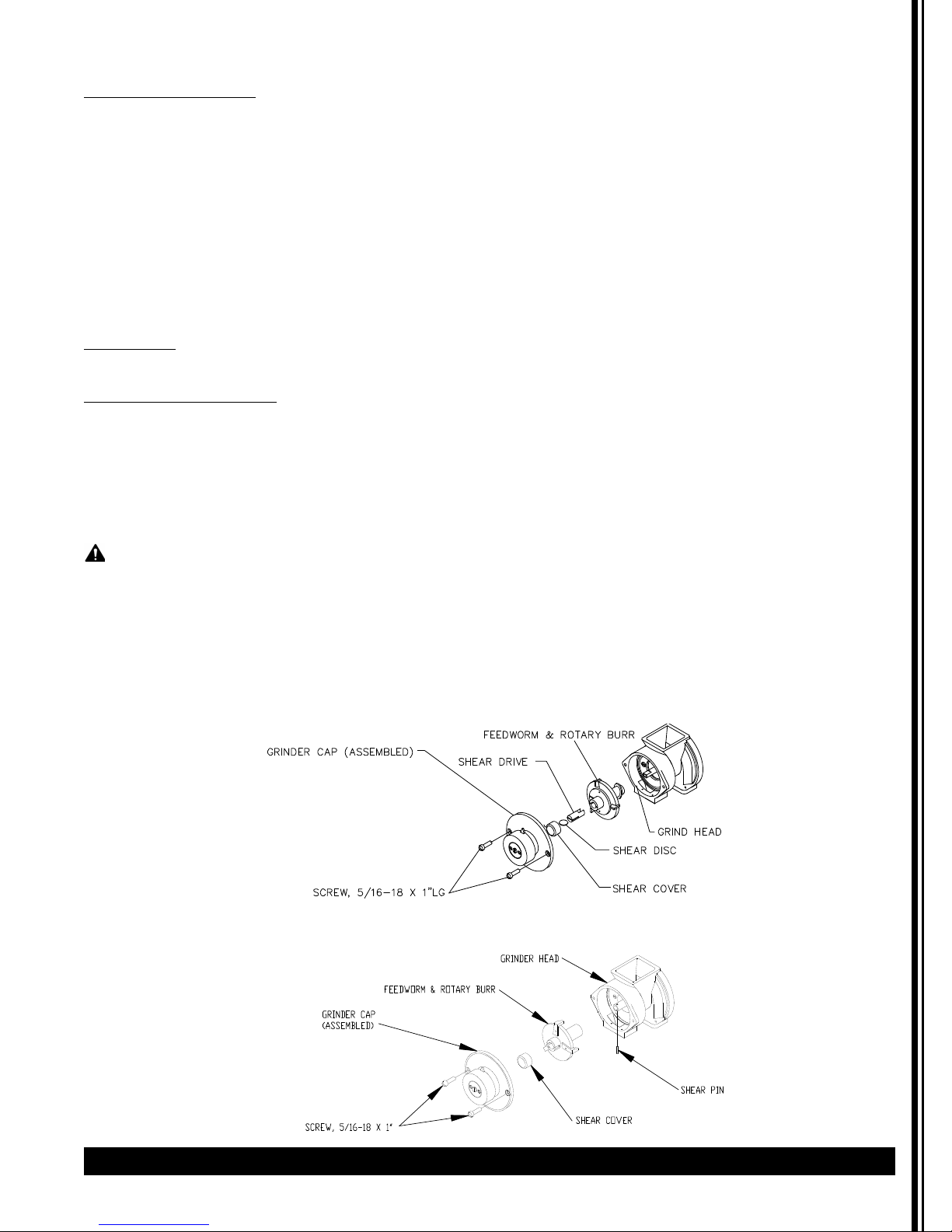

This grinder is equipped with both a circuit breaker and

a shear disc or shear pin to protect motor and burrs.

Circuit Breaker

This grinder is equipped with a circuit breaker to

protect the motor from overloading. When the circuit

breaker trips, the reset button will pop out

approximately 1/4” which stops the power to the

grinder. The reset button is located on the front panel

of the Model 810, 835 and 875. To reset the circuit

breaker, wait two minutes then push in the reset

button. You will hear a click as it resets. If the grinder

does not operate after resetting the circuit breaker,

there may be an obstruction in the grinding

mechanism that is stalling the motor. Turn the grind

selector knob all the way to the left. Try restarting the

grinder. If the circuit breaker “trips” again, the

obstruction was not able to pass. In this case, the

Grinder Head should be cleaned out as described in the

Shear Disc Replacement section of this manual.

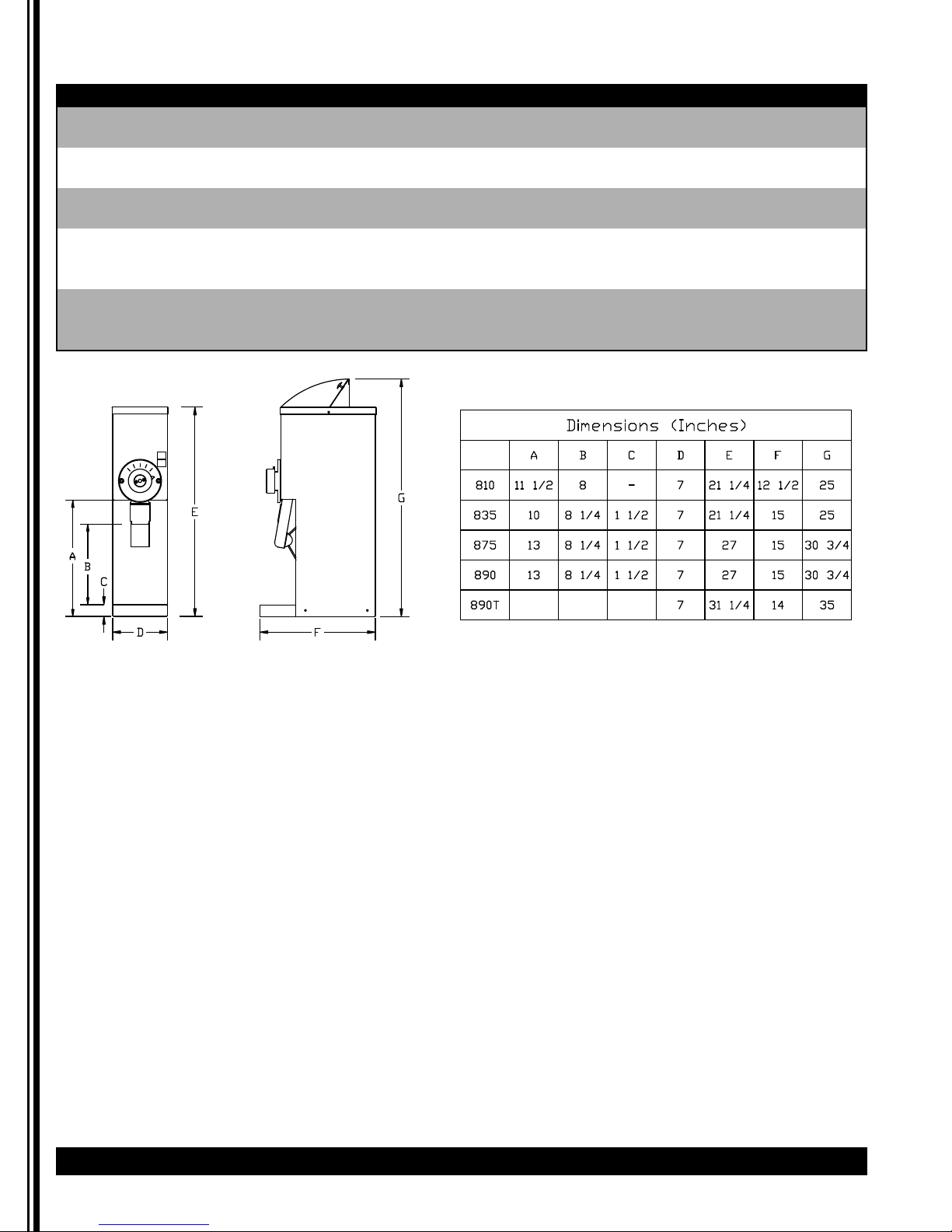

4 Grindmaster®800 Series Coffee Grinders

Operation