Your tool will last longer and perform better if periodic maintenance is

performed. Please use the information below to keep your tool operating

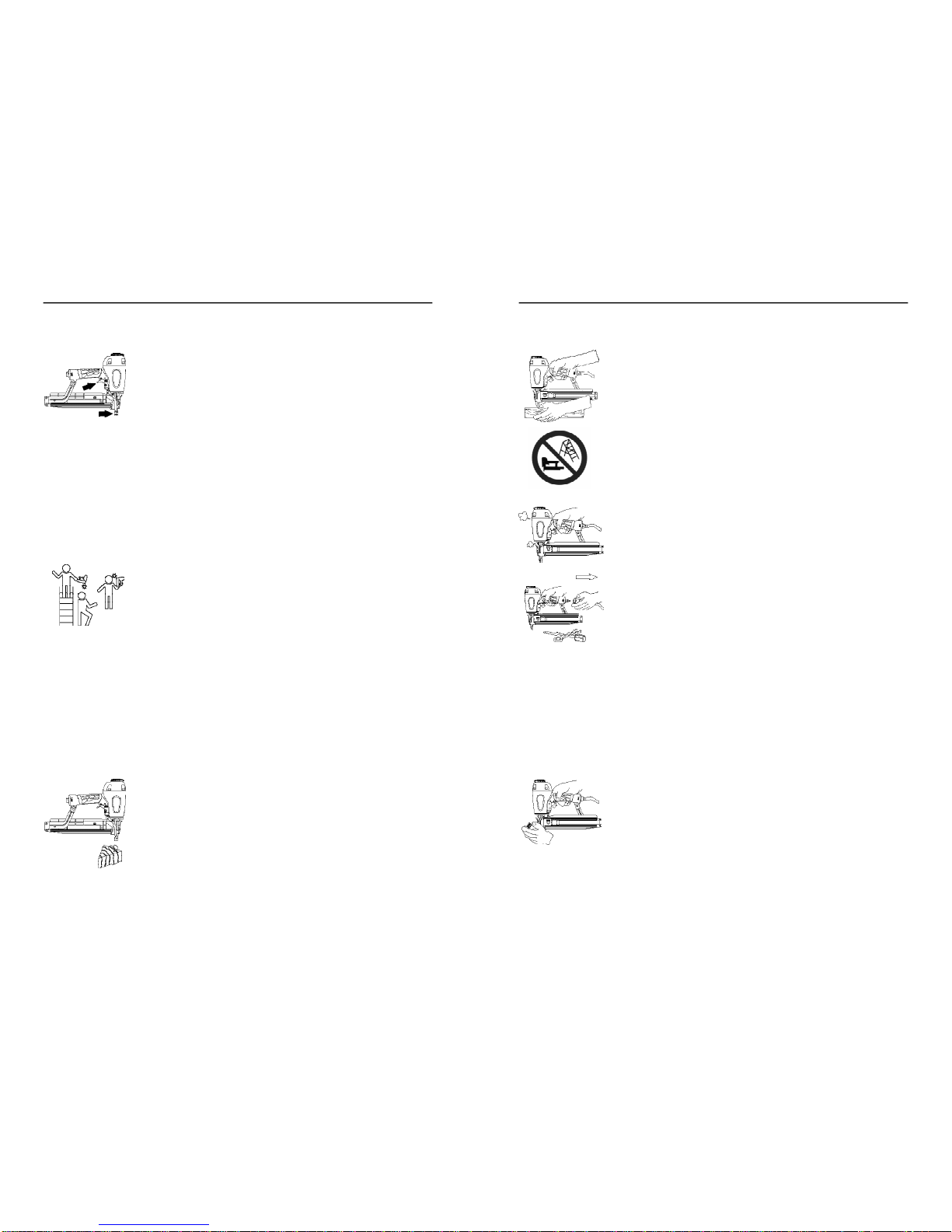

Disconnect tool from the air supply and remove all

fasteners. Apply 2 - 3 drops of air tool oil (pro-

vided) in the air inlet two - three times a day. If

the tool will be used outside in the winter, use a

winter gradeair tool oil to help keep frost from

forming inside thetool. Do not use other types of

lubricants on this tool, as other lubricants may

containchemicalsharmfulto o-ringsandother

tool components. Drain compressor tanks and

Disconnect tool from the air supply andremove all fasteners. Brush tool

off using a partscleaning brushor clean rag. Check area aroundtrigger

and workpiece contact, and clean as necessary. Pull pusher back to

latched position, and brush out staple entry area of tool nose. OpenE-Z

Clear latchand brush out debris. Blowout confinedareasaroundtool nose

usinglowpressurecompressedair.

Trigger Check (Sequential)

Checktriggeroperationdailytoconfirm propersequentialoperation:

Presstheworkpiece contact against a safe work surface without

Holdthetool above asafe work surfaceand pull thetrigger without

depressingtheworkpiececontact.

Pull and holdthe trigger, and thenpressthe workpiece contact

againsta safeworksurface.

With finger off trigger, press theworkpiece contact against a safe

work surface. Keep tool pressed against work surface, andpull

Thetrigger must returntothe normal position each time finger

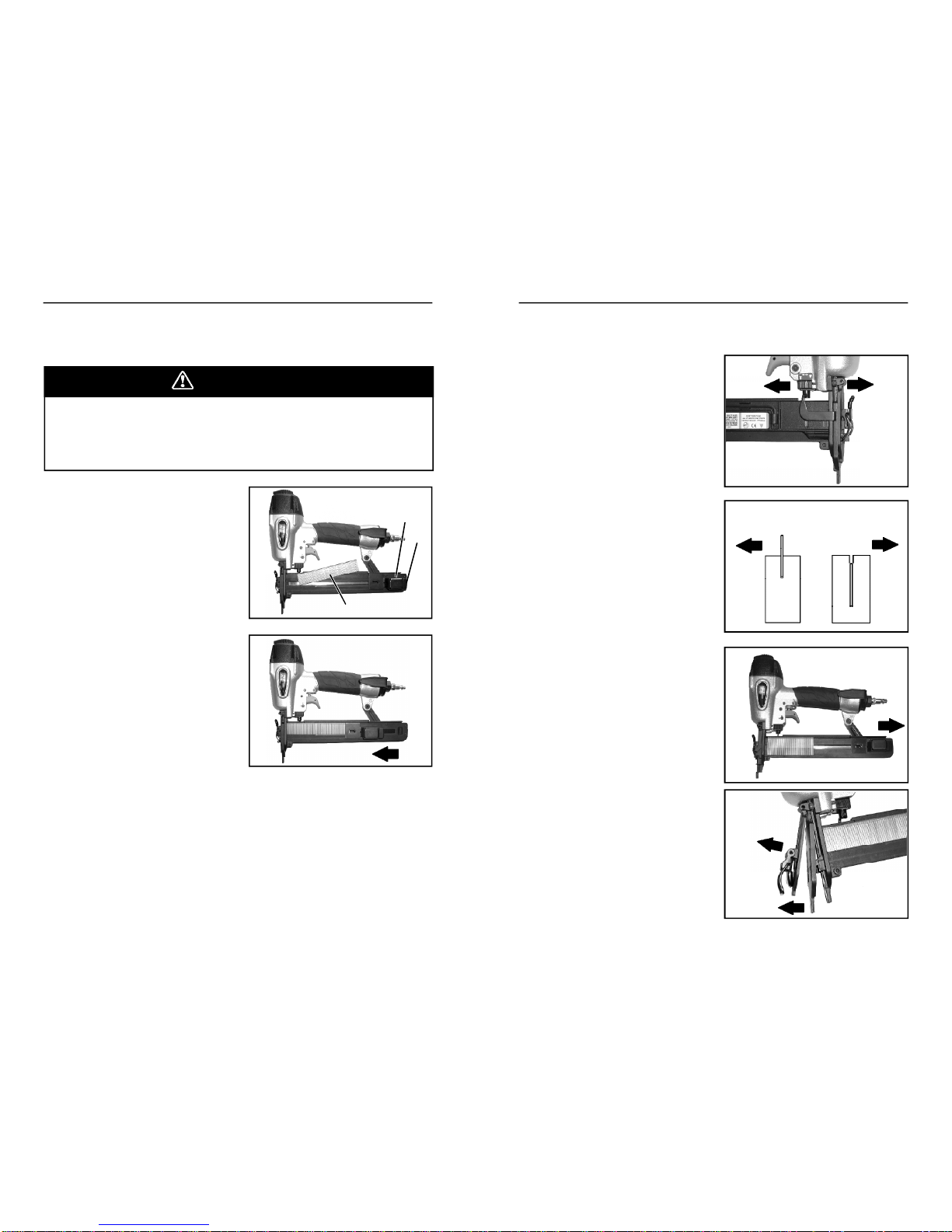

SEQUENTIALOPERATION(Standard)

Hold the tool securely using the handgrip. Keepfinger off trigger

until tool is inposition and you are ready todrive a fastener. NOTE:

Depressing trigger before depressingsafety bracket will prevent tool

Position the nose of the tool on the workpiece, placing the nose at

thedesiredfastenerdrivingposition.

Pressthe tool down firmly against the work surface, fully depressing

the workpiece contact (safety bracket).

Squeeze the trigger onceto drive a fastener.

Allow the tool to rebound off thework surface, and release the trigger

to resetthe workpiece contact. Tool will not drive anotherfastener

until triggeris released, and cannot be bump-fired with sequential

Checkfastener for correct depthof drive,and if needed, adjust lower

element tip toobtaindesiredfastener drive.

If tool adjustments donot providethe desired results, make air

pressure adjustments at the compressor: Increase air pressure to

drivedeeperor to drive into hardermaterials. Reduceair pressure to

reduce driveor to drive into softer materials. For longesttool and

part life, always use thelowest air pressure necessary to drive

fastenersto desireddepth.

Positionthe tool fordriving thenext fastener, andrepeat theabove

procedure. Alwayskeep handsand other body parts away from

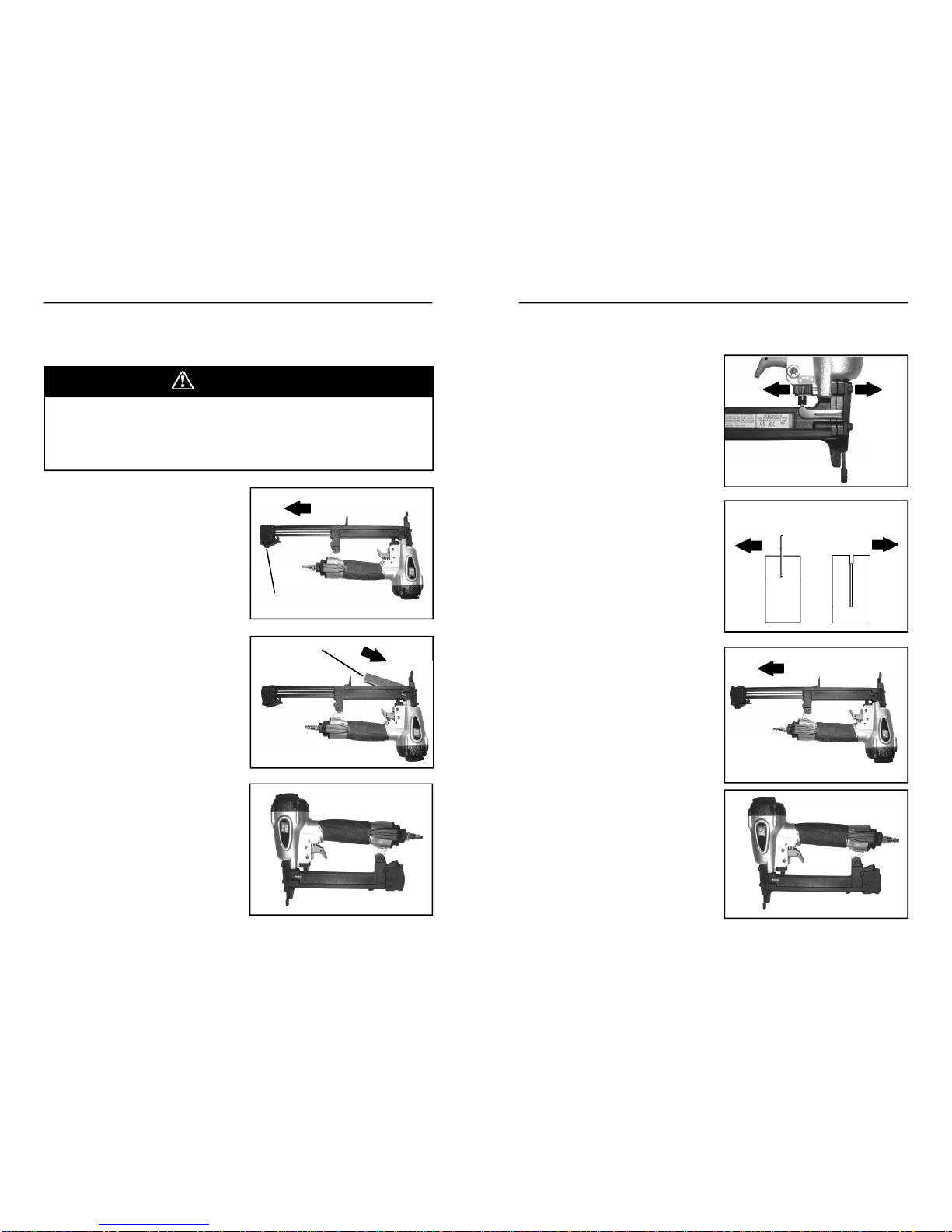

CONTACT TRIP (BUMPFIRE)DRIVINGMETHOD(Optional)

To operate thistool incontact trip mode(bump-firing), remove the sequen-

tial trigger providedon thetool, andinstall thedual-actiontriggerprovided

Positionthe noseof thetool over the work surface, nearthe area

where the first fastener isto be driven.

Squeeze and hold the trigger in thedepressed position.

Bump the workpiece contact (safety) against the work surface at

eachpoint where a fastener is tobe driven.

Using abouncingmotion, continue moving thetoolintopositionfor

Whenfastening iscompleted, release thetrigger.