General Instructions

1. Always press on the inner ring of a ball–type bearing when

installing the bearing on a shaft.

2. Always press on the outer ring of a ball–type bearing when

pressing the bearing into a bearing recess.

3. When grasping a tool or part in a vise, always use

leather–covered or copper–covered vise jaws to protect the

surface of the part and help prevent distortion. This is particularly

true of threaded members and housings.

4. Except for bearings and mechanism parts, always clean every part

and wipe every part with a thin lm of oil before installation.

5. Wipe a thin lm of mechanism uid on all internal mechanism

components before installing them in the mechanism.

6. Apply a lm of o–ring lubricant to every o–ring before

installation.

Assembly of the Motor

1. If the Reverse Valve Bushing Seal (10) was removed from the

reverse valve bushing, install a new Seal inside the bushing.

2. Install a new Reverse Valve Seal (9) on the Reverse Valve (8).

3. Being careful not the cut or nick the Seals, insert the Reverse

Valve, large hub trailing, into the Motor Housing (1) from the lever

side of the Housing. Make certain the hole for the Reverse Lever

Retaining Pin (4) and the valve porting are properly aligned.

4. Position the Throttle Lever (11) on the Housing and secure it by

pressing the Lever Retaining Pin (12) through the Housing and

Lever.

5. Install the Throttle Rod Seal (6) in the groove on the large hub of

the Throttle Rod (5).

6. Install the Reverse Lever Seal (3) on the hub of the

Reverse Lever (2).

7. Insert the Throttle Rod Assembly, small end leading, into the

Reverse Valve Assembly followed by the Throttle Rod Spring (7)

and assembled Reverse Lever.

8. Align the hole in the Reverse Lever with the hole in the Reverse

Valve and install the Reverse Lever Retaining Pin in the aligned

holes.

9. Place the Exhaust Deector Seal (14) on the inlet and of the

Motor Housing followed by the Exhaust Deector.

10. Thread the Inlet Bushing (15) into the small hub the Housing and,

after rotating the Deector to the desired position, tighten the

Inlet Bushing between 30 and 35 ft–lb (40 and 47 Nm) torque.

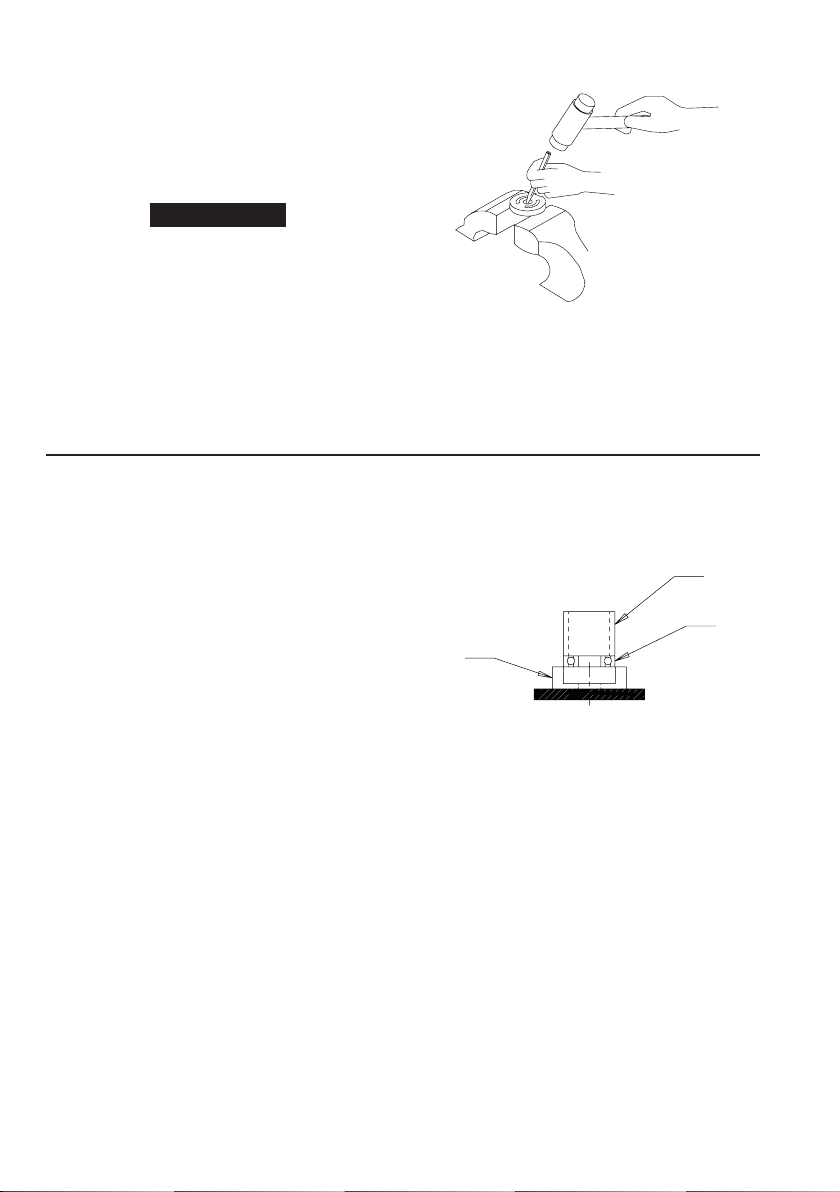

11. Using an arbor press and a piece of tubing that contacts the outer

ring of the bearings, press the Front End Plate Bearing (27) into

the Front End Plate (25) and the Rear End Plate Bearing (19) into

the Rear End Plate (18).

(Refer to Dwg. TPD1274).

(Dwg. TPD1274)

12. Stand the Rotor (25) on the table of an arbor press. It should be

upright on a at metal plate having a clearance hole for the shaft.

The shaft with the hex must be downward.

13. Place a 0.001”(0.025 mm) shim on the upward surface of the large

portion of the rotor body. Using a piece of tubing that contacts

the inner ring of the bearing, press the Rear Rotor Bearing and

Rear End Plate, End Plate leading, onto the shaft of the Rotor until

the End Plate contacts the shim. Remove the shim.

14. Coat each Vane (24) with a thin lm of oil and insert a Vane into

each of the rotor vane slots with the straight edge of the Vane

outward.

15. Install the Cylinder (20) over the Vanes and Rotor with the end of

the Cylinder having the two holes in straight alignment nearest

the end face positioned away from the Rear End Plate. Make

certain the End Plate Dowel (24) enters the hole in the face of the

Rear End Plate and not the porting slot.

16. Place the Front End Plate and Bearing against the face of the

Cylinder, Bearing end trailing. Make certain the End Plate Dowel

in that end of the cylinder enters the hole in the End Plate and

not the porting slot.

17. Place the Rear End Plate Spacer (17) against the Rear End Plate

making certain that the Rear End Plate Dowel enters the hole in

the Spacer and the external slots align.

4. Remove the motor from the vise jaws and remove the Front End

Plate (25), Front Rotor Bearing (27), Cylinder Assembly (20) and

Vanes (24) from the Rotor.

5. Remove the Rear End Plate Spacer (17) from the Motor Housing

or the Rear End Plate (18).

6. On the table of an arbor press, support the Rear End Plate with

blocks as close to the Rotor as possible and press the Rotor out of

the Rear End Plate and Rear Rotor Bearing (19).

In the following step, do not enlarge or damage the

shaft hole in the End Plate when removing the

Bearing.

7. To remove the Rear Rotor Bearing from the Rear End Plate, use a

small drift or pin punch through the central opening of the Rear

End Plate to tap the Bearing out of the End Plate.

(Refer to Dwg. TPD1271)

8. Using an adjustable wrench, unscrew and remove the Inlet

Bushing (15). Remove the Exhaust Deector (13) and Exhaust

Deector Seal (14).

9. Using a pin punch and without damaging the Reverse Lever (2),

remove the Reverse Lever Retaining Pin (4) and separate the

Lever from the Reverse Valve Assembly (8). Remove the Reverse

Valve Seal (9) from the Lever.

(Dwg. TPD1271)

10. Remove the Throttle Rod Assembly (5) and Throttle Rod Spring (7)

from the Reverse Valve Assembly (8).

11. Using a pin punch, tap the Lever Retaining Pin (12) out of the

Throttle Lever (11) and Housing and remove the Lever.

12. Push the Reverse Valve Assembly out the lever side of the

Housing.

Assembly