ECCO

EIB 12/06-01

9836 3178 01

2007-10

ENGLISH • Operator’s Instructions

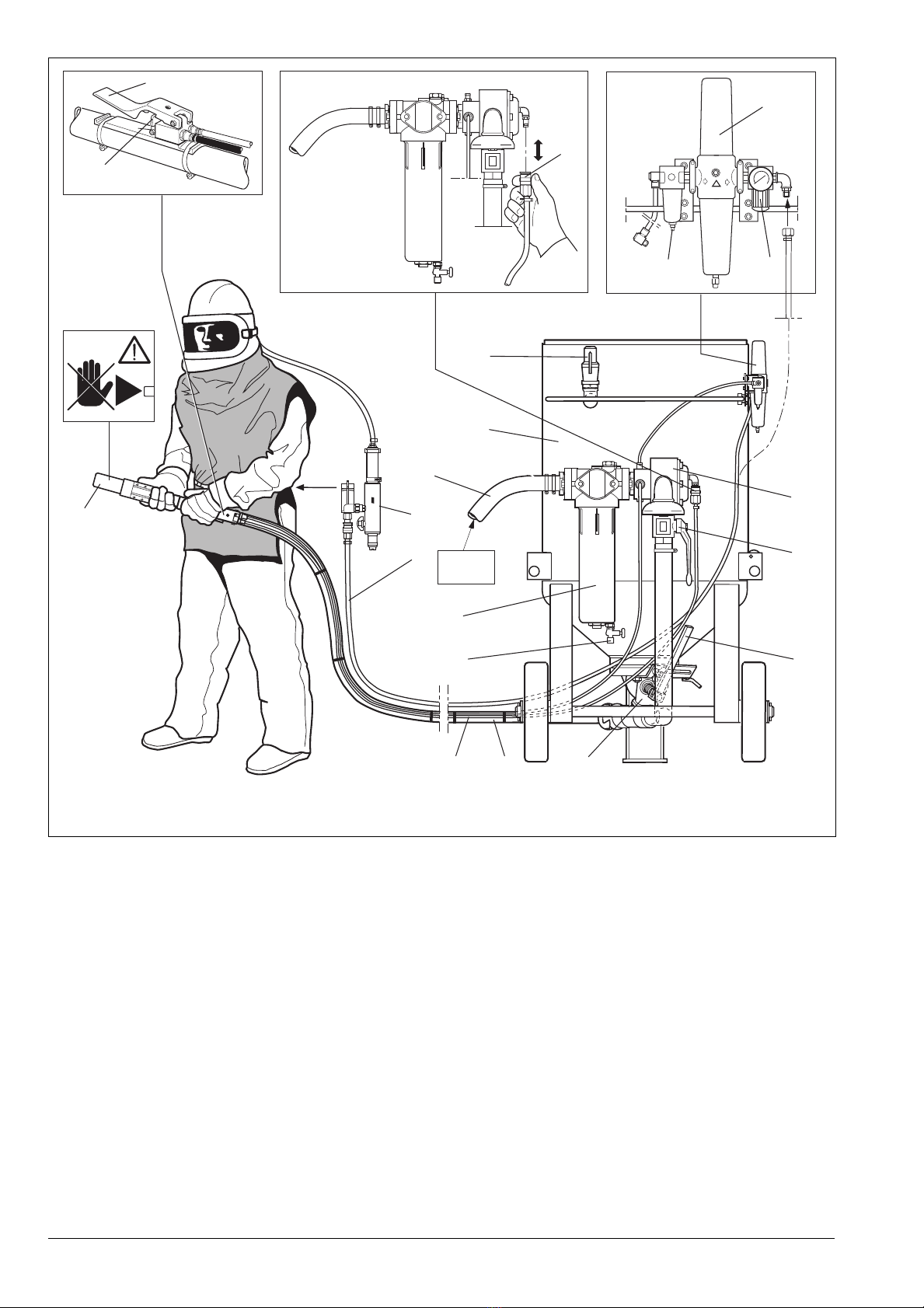

Equipment for free-jet blasting.

• At the end of each working day the abrasive valve must be closed

and residual abrasive blown out of the branch pipe and hose.

• If the blast unit is to be taken out of service for a prolonged period

it must be emptied of blasting medium and stored in a dry place.

• The lifting eye is approved for loads of up to 1400 kg.

Maintenance

• The interior condition of the abrasive container should be in-

spected regularly for corrosion.

• Unscrew the safety valve (see J Fig.1), including the tee, from the

abrasive container every now and then and clean out any abra-

sive found in the tee.

• Check wear and consumption parts (parts marked with bold type

in the part numbering according to the spare parts list) regularly.

Change damaged or worn parts. The cone in the diaphragm valve

and the valve discs in the abrasive valve are reversible.

Starting (see Fig. 1)

1. Fill abrasive into the blast unit.

2. Check that the air hose, control hoses (twinline hose) and the

blast hose are right connected to the blast unit and the blast

nozzle is correctly tightening in the holder on the blast hose.

3. Close manual drain valves on the moisture trap and the air filter.

4. Connect compressed air.

5. Put on the blast helmet (S) and adjust the air pressure (Q) 5–7 bar.

6. Adjust the worm or cold air to the blast helmet on the air thermostat

(T) (the fig. shows the warm connection, for cold air reverse the

thermostat).

For warm air:

Warmer air is obtained when the air flow is throttled

with the control valve.

Forcoldair:

Colderairisobtainedwhenthecontrolvalveisopened

but the air flow is reduced.

7. Check that the valve (I) is fully open. This valve is used to throttle

the air supply to the abrasive valve when small blast nozzles are

used, or as a shock valve (rapid closing-opening) if the flow of

abrasive to the blast nozzle becomes uneven.

8. Hold the blast hose and the blast nozzle firmly and press in/

down the safety catch (F) and depress the lever on the dead-

man’s handle (E).

9. Set the flow of abrasive to the blast nozzle with the lever (L) on

the blast valve (K).When the lever (L) is moved towards the

adjustable stop the flow of abrasive increases and when it is

moved towards the fixed stop the flow decreases.Adjust the

sand valve to smallest amount possible. It is wrong to use more

sand than necessary.

10. Set the adjustable stop for the lever (L) on abrasive valve. Thus,

after closing, it is possible to open rapidly again to the previously

set rate of abrasive flow.

Stopping (see Fig. 1)

Release the lever (E) on the dead-man’s handle. The air supply is

thus cut off and the unit is depressurized.

OBS! Blasting can also be stopped, emergency stop, by

disconnecting the quick coupling (G) on the blue operating air hose

from diaphragm valve.

After finished blasting or when making a break, the quick coupling

(G) shall always be disconnected from the diaphragm valve.

BRC = Blast unit with pneumatic remote control device (Remote

control with dead-man’s handle and double control hoses).

Use Ecco genuine parts and accessories only for best

function and safety.

Before starting, read through all instructions carefully.

Ecco BRC 120 Pack, -200 Pack, -300 Pack

Important

The safety measures prescribed in the relevant regulations

must be complied with.

Always wear protective garments when blasting, blast helmet,

blast gloves and blast overall.

The breathing air supplied to the blast helmet must be free

of oil and filtered through an effective filter.

Use only approved air hose for breathing air.

Never aim the blast nozzle at a person or towards any part of

the body.

Use only approved abrasives.

Wear suitable eye protection when filling unit. There is a

possibility that some abrasive may be blown back as the

pop-up valve seats.

Depressurize unit before loading media or any maintenance

is performed.

Make sure that the claw couplings on air- and blast hoses are

secured by means of lock springs.

WARNING

• Blow the air hose clean before connection.

• The compressed air to the blast unit must have a shut off valve.

• The compressed air must be dry and clean.

• Drain the condensate out of the moisture trap and the air cleaner

every day (see O and R Fig.1). MTA are also equipped with auto-

matic drain system.

• The size of the blast hose must be suited to that of the blast

nozzle (usually 3 to 4 times the bore of the nozzle).

• The blast hose must be trimmed at right angels before a nozzle

holder or claw coupling is fitted.

• To prevent unnecessary wear on the blast hose, sharp bends on

the hose must be avoided.

Principal data

Type Max. working Air hose Container Weight

pressure connection volume

Ecco bar l kg

BRC 120 Pack 10.5 Couplinga) 120 146

BRC 200 Pack 10.5 Couplinga) 195 194

BRC 300 Pack 10.5 Couplinga) 290 220

a) With nipple for hose bore 40 mm (1 1/2").