Operation &

Maintenance

Manual

A6ML0066 –Euroblast SF Instruction Manual

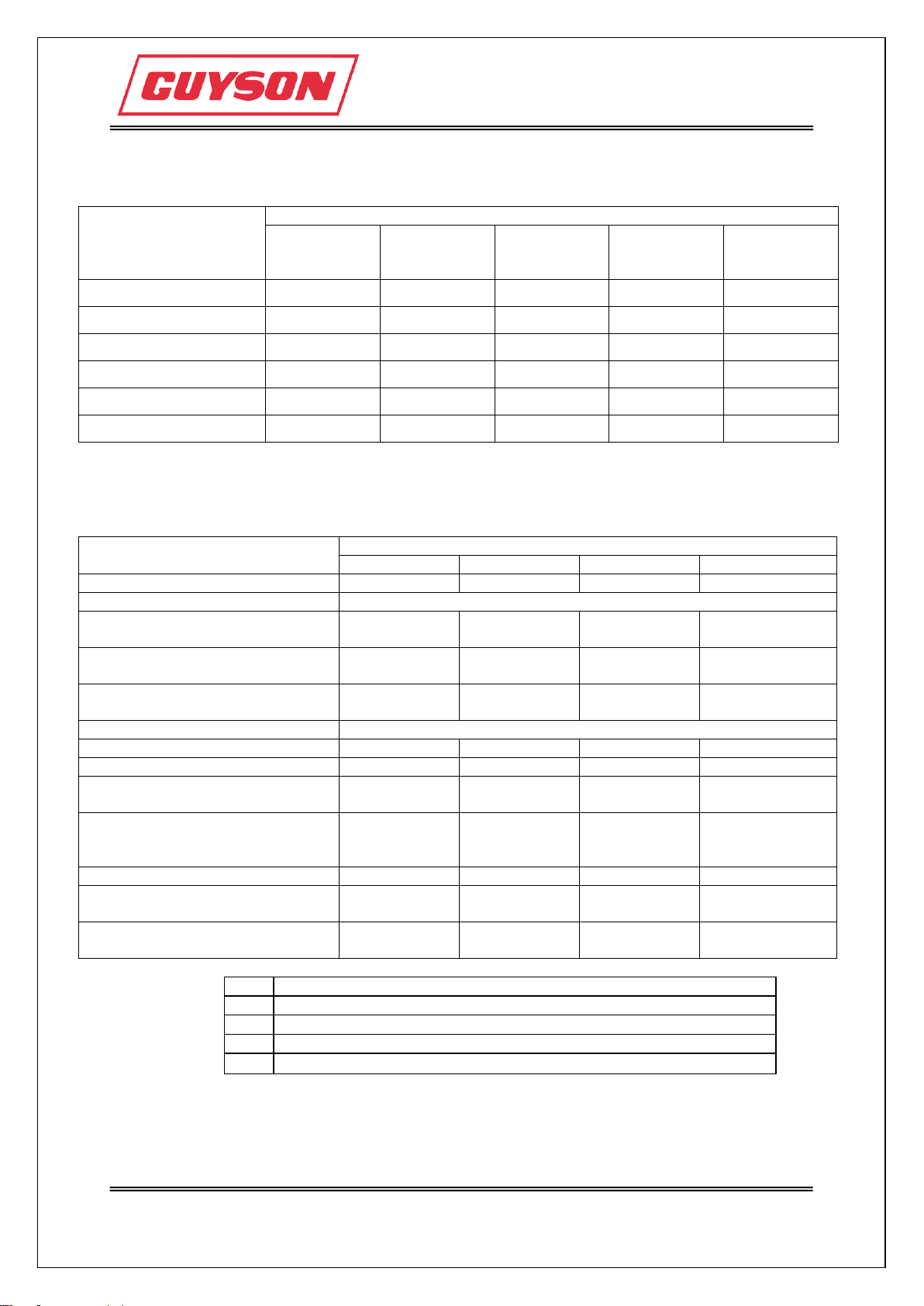

Table of contents

1. Introduction .........................................................................................................................................4

1.1 Safety recommendations..............................................................................................................4

1.2 Electrical specification ..................................................................................................................4

1.3 Blast media...................................................................................................................................5

2. Data sheets.........................................................................................................................................7

2.1 Blast cabinets................................................................................................................................7

2.2 Cyclones.......................................................................................................................................8

2.3 Dust collectors ..............................................................................................................................8

2.4 Air consumption tables .................................................................................................................9

2.4.1 Air flow measured in m³/hr at different pressures measured in bar.......................................9

2.4.2 Air flow measured in CFM at different pressures measured in psi........................................9

3. Installation.........................................................................................................................................10

3.1 Location ......................................................................................................................................10

3.2 Assembly ....................................................................................................................................10

3.2.1 Compressed air connections ...............................................................................................13

3.2.2 Electrical connections ..........................................................................................................15

4. Testing installation ............................................................................................................................16

4.1 Testing installation procedure.....................................................................................................16

4.2 Media levels................................................................................................................................19

4.2.1 Adding media to hopper.......................................................................................................19

4.2.2 Adding media to 75/16 cyclone............................................................................................19

4.2.3 Adding media to CY600 cyclone..........................................................................................20

5. Machine settings ...............................................................................................................................21

5.1 Blast settings...............................................................................................................................21

5.1.1 Blasting pressure .................................................................................................................21

5.1.2 Media pick-up tubes.............................................................................................................22

5.1.3 Stand-off distance ................................................................................................................23

5.1.4 Angle of blasting...................................................................................................................23

5.2 Extraction settings ......................................................................................................................23

5.2.1 Dust collector .......................................................................................................................23

5.2.2 Cyclone ................................................................................................................................25

6. Operation ..........................................................................................................................................27

6.1 Operating procedure...................................................................................................................27

7. Maintenance......................................................................................................................................28

7.1 Daily............................................................................................................................................29

7.1.1 Breather pads.......................................................................................................................30

7.1.2 Viewing and illumination window .........................................................................................31

7.1.3 Hoses...................................................................................................................................32

7.1.4 Pick up tubes and mixer box................................................................................................33

7.1.5 Blast nozzles........................................................................................................................34

7.1.6 Door seals............................................................................................................................37

7.1.7 Overspray.............................................................................................................................37

7.1.8 Empty waste bin...................................................................................................................38

7.1.9 Topping up media ................................................................................................................39

7.1.10 Filter cleaning.....................................................................................................................39

7.1.10.1 Replacing the filter sleeves on a 41............................................................................41

7.1.10.2 Replacing the filter cartridge on a C400......................................................................42

7.1.10.3 Replacing the filter cartridge on a C600......................................................................43

7.1.10.4 Replacing the filter cartridges on a C800....................................................................44

7.1.10.5 Replacing the HEPA14 Filter Cartridge, C600 Dust Collector....................................45

7.1.10.6 Replacing the HEPA14 Filter Cartridge, C800 Dust Collector....................................46

7.1.10.7 Bin Balance Breather Sock.........................................................................................47

7.1.10.8 Autopulse, C400 and C600.........................................................................................48