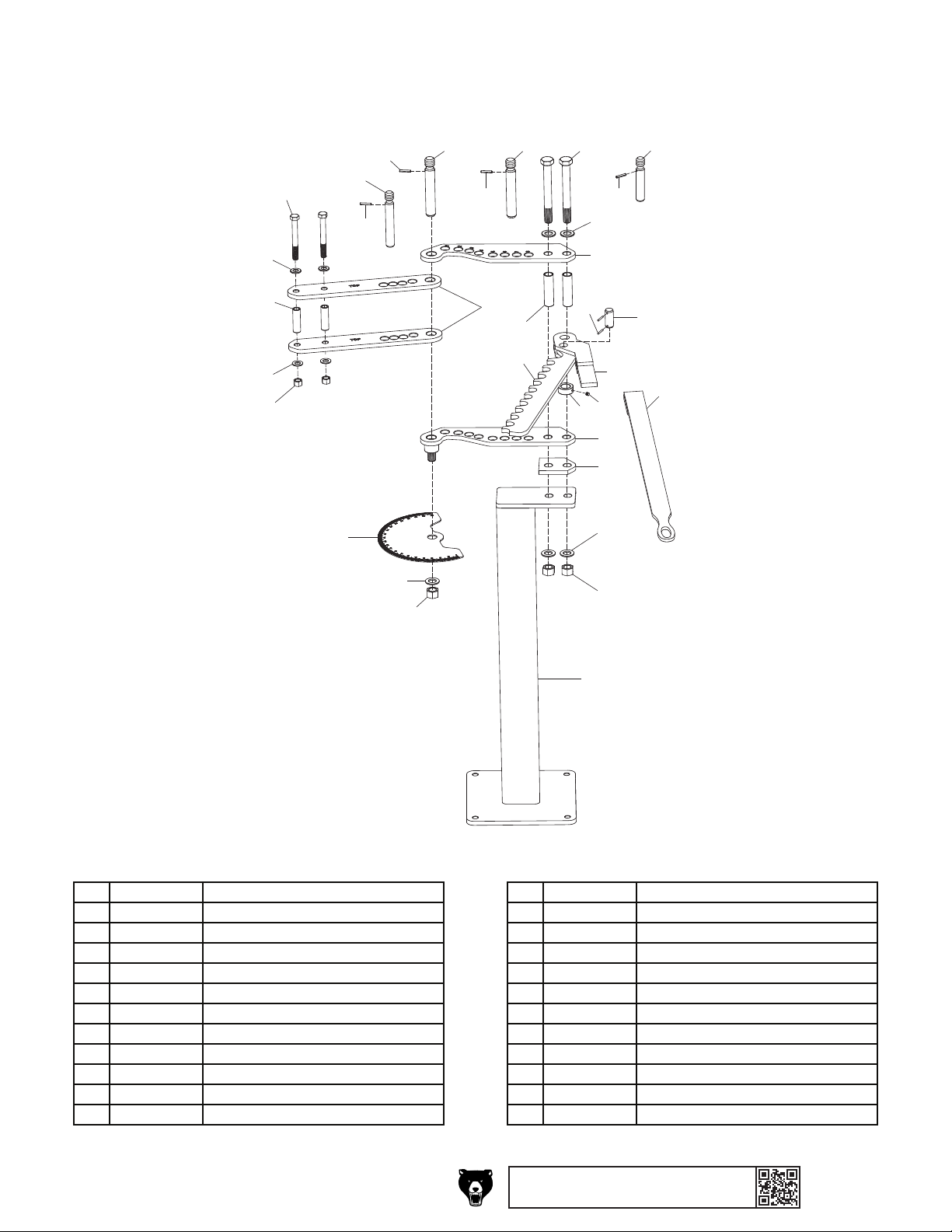

Frame

Pin

Drive

Pin

M14-2 x 110

Hex Bolt

14mm

Flat Washer

14mm

Flat Washer

M14-2

Hex Nut

Drive

Link

Drive

Link Drive Link

Spacer

Figure 6. Drive link assembly setup.

Figure 5. Completed frame assembly.

Model T30860 (Mfd. Since 12/19) -3-

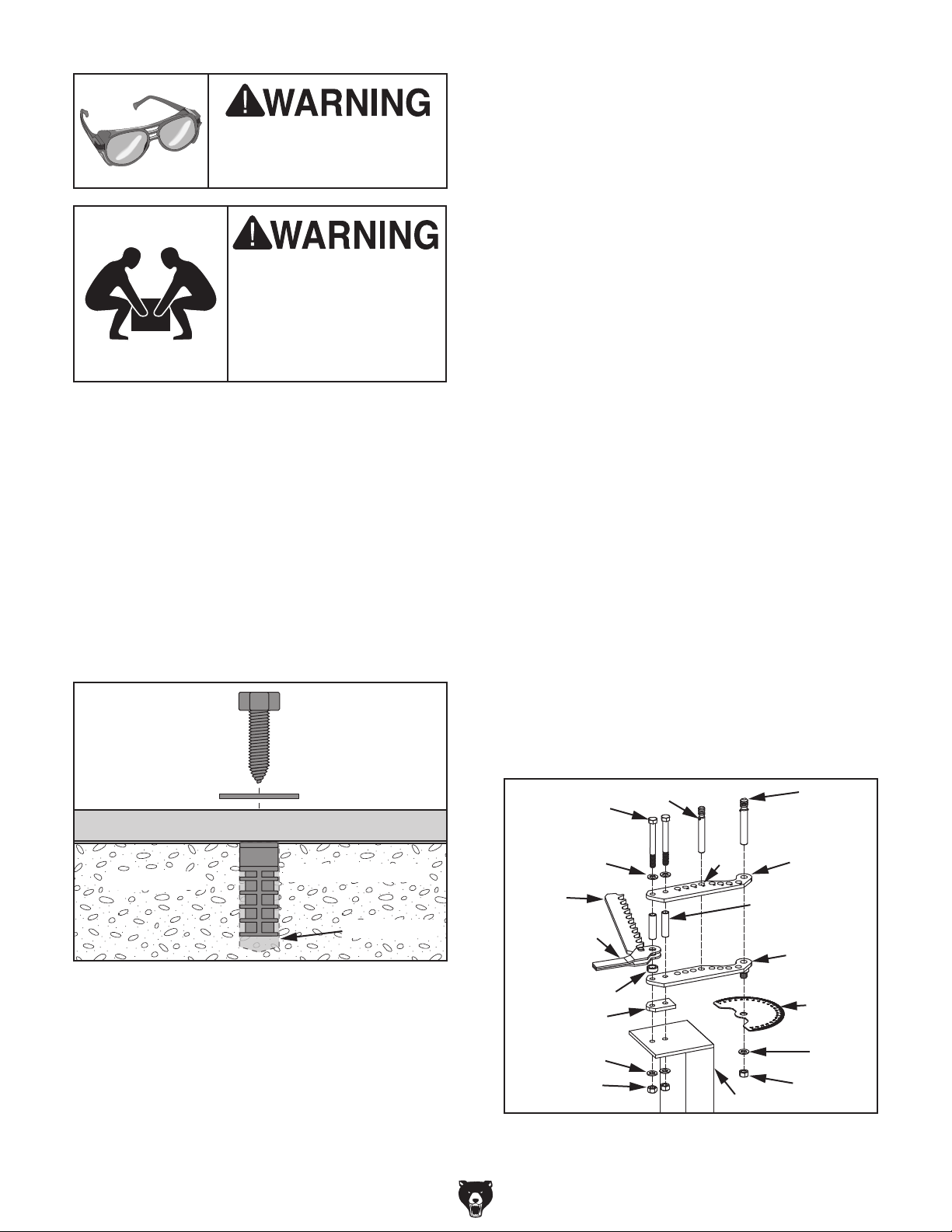

5. Insert M20-2.5 x 175 hex bolts with 20mm

flat washers through upper frame link, frame

spacers, swing lever, collar, lower frame

link, frame base, and stand (see Figure 4).

Secure with 20mm flat washers and M20-2.5

hex nuts (only hand tighten for now).

6. Insert frame pin through upper and lower

frame links (see Figure 4).

7. Insert drive pin into #5 hole as shown in

Figure 4.

8. Fully tighten both hex nuts installed in Step

5. Verify drive pin and frame pin are able to

slide through their respective holes.

9. Raise swing lever to middle of frame spacer

and lock into position by tightening set screw

on collar with 4mm hex wrench.

10. Install bend angle indicator, 20mm flat wash-

er, and M20-2.5 hex nut onto lower frame link

(see Figure 4) and hand tighten.

Note: This nut should never be tightened with

a wrench. This allows the bend angle indica-

tor to be adjusted while bending.

11. Verify frame is assembled as shown in

Figure 5.

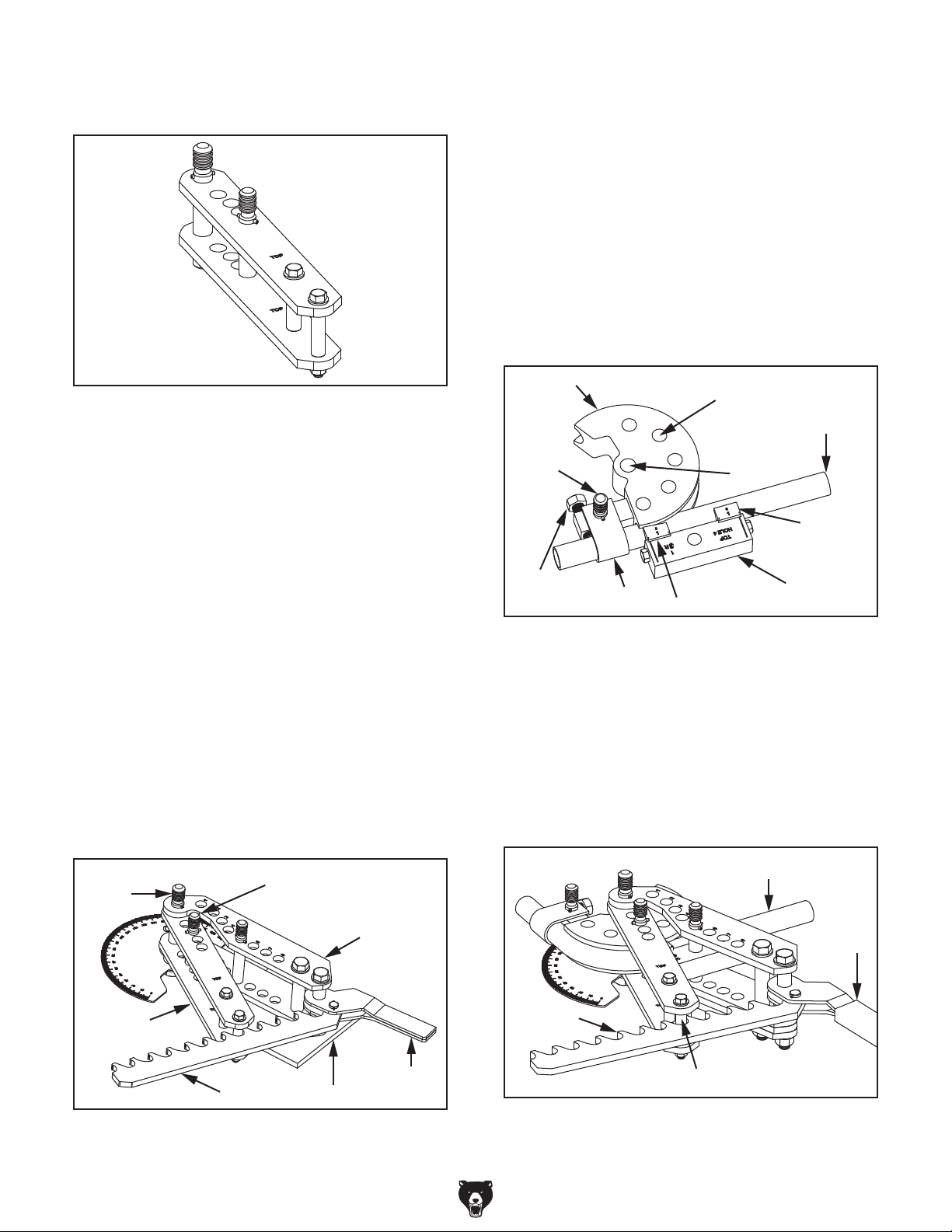

Drive Link Assembly Setup

1. Place both drive links (see Figure 6)on their

side with "TOP" stamp facing same direction.

Note: Drive link "TOP" stamp must face

same direction on both drive links since three

of four drive holes are offset to the right.

2. Insert M14-2 x 110 hex bolts with 14mm flat

washers into upper drive link holes shown in

Figure 6.

3. Install drive link spacers (see Figure 6)over

hex bolts and insert threaded end of hex bolts

through lower drive link holes.

4. Secure hex bolts with 14mm flat washers and

M14-2 hex nuts, and hand tighten.

5. Insert frame pin and drive pin through drive

link holes shown in Figure 6.

Note: The frame pin is shared between

assemblies for alignment purposes only dur-

ing setup.

6. Fully tighten both hex nuts installed in Step

4. Verify drive pin and frame pin are able to

slide through their respective holes.