-5-

Model T33955 T33956 (Mfd. Since 09/23)

SECTION 2: SETUP

The following items are needed, but not included,

for the setup/assembly of this instrument.

Description Qty

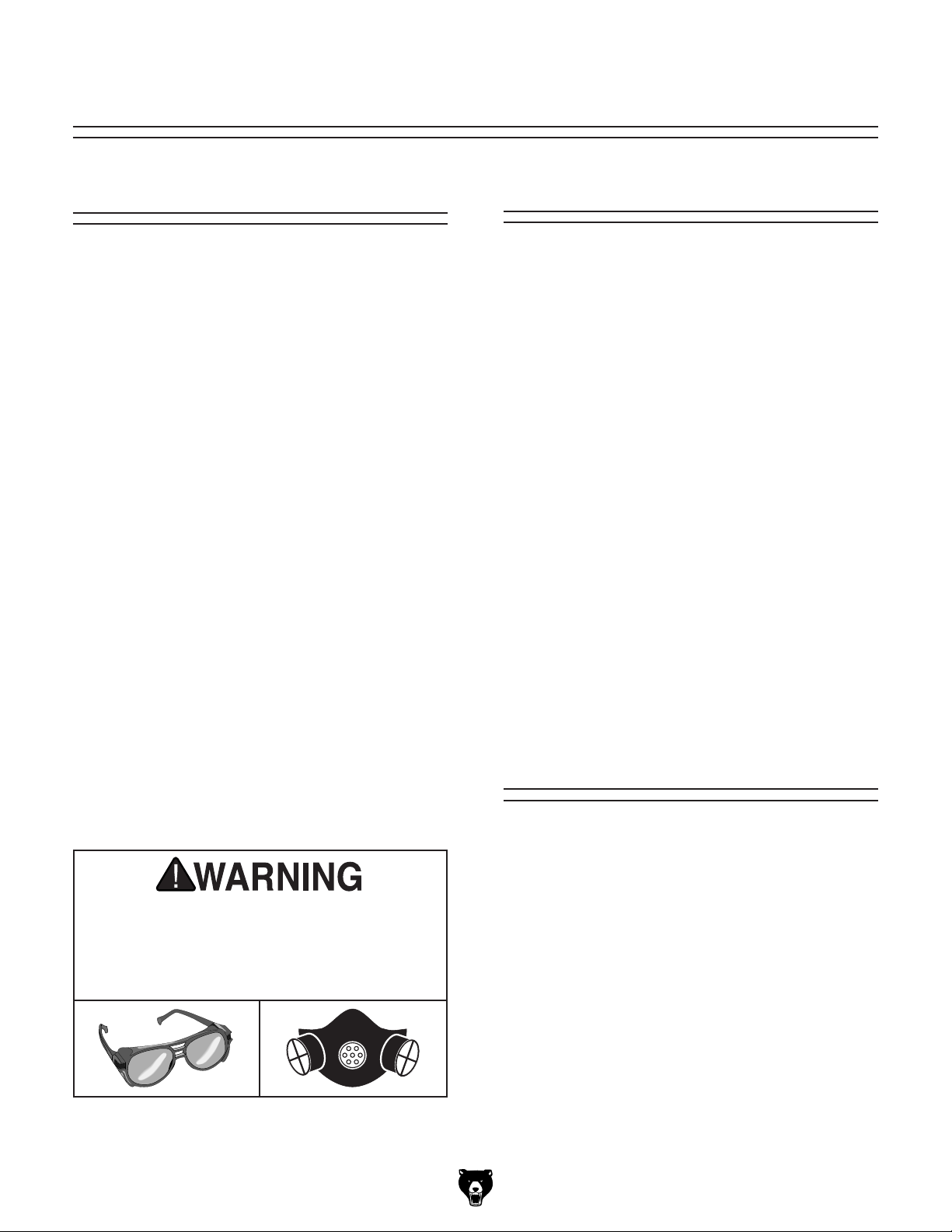

• Safety Glasses ........................................... 1

• NIOSH-Approved Respirator ...................... 1

• Sanding Block ............................................ 1

• Drill Press or Cordless Drill w/Depth Stop... 1

• Drill Bit Set.................................................. 1

•

Phillips Screwdriver Set

............................... 1

• Pencil.......................................................... 1

• Sanding Block ............................................ 1

• Hobby Knife or Razor Blade ...................... 1

• Wood File Set............................................. 1

•

Soldering Iron and Solder

............................ 1

• T-Handle Reamer (1⁄8" to 5⁄8") ..................... 1

• Non-Marring Mallet..................................... 1

• Wire Cutters ............................................... 1

• Needle Nose Pliers .................................... 1

• Feeler Gauge Set ....................................... 1

•

18" Metal Straightedge (

1

⁄

32

" Resolution)

...... 1

• Wood Glue ................................. As Needed

• Super Glue ................................. As Needed

• C-Clamps ................................... As Needed

• Disposable Gloves ..................... As Needed

• Sandpaper #180, #240, #320,

• #800, #1000 ............................... As Needed

•

Tack Cloth or Soft Cloth

............... As Needed

• Masking Tape or Painter's Tape. As Needed

• Finishing Supplies ...................... As Needed

• Tack Cloth................................... As Needed

• Lint-Free Rags............................ As Needed

• Wooden Blocks .......................... As Needed

• Wooden Shims ........................... As Needed

• Wood File Set (Optional) ............................ 1

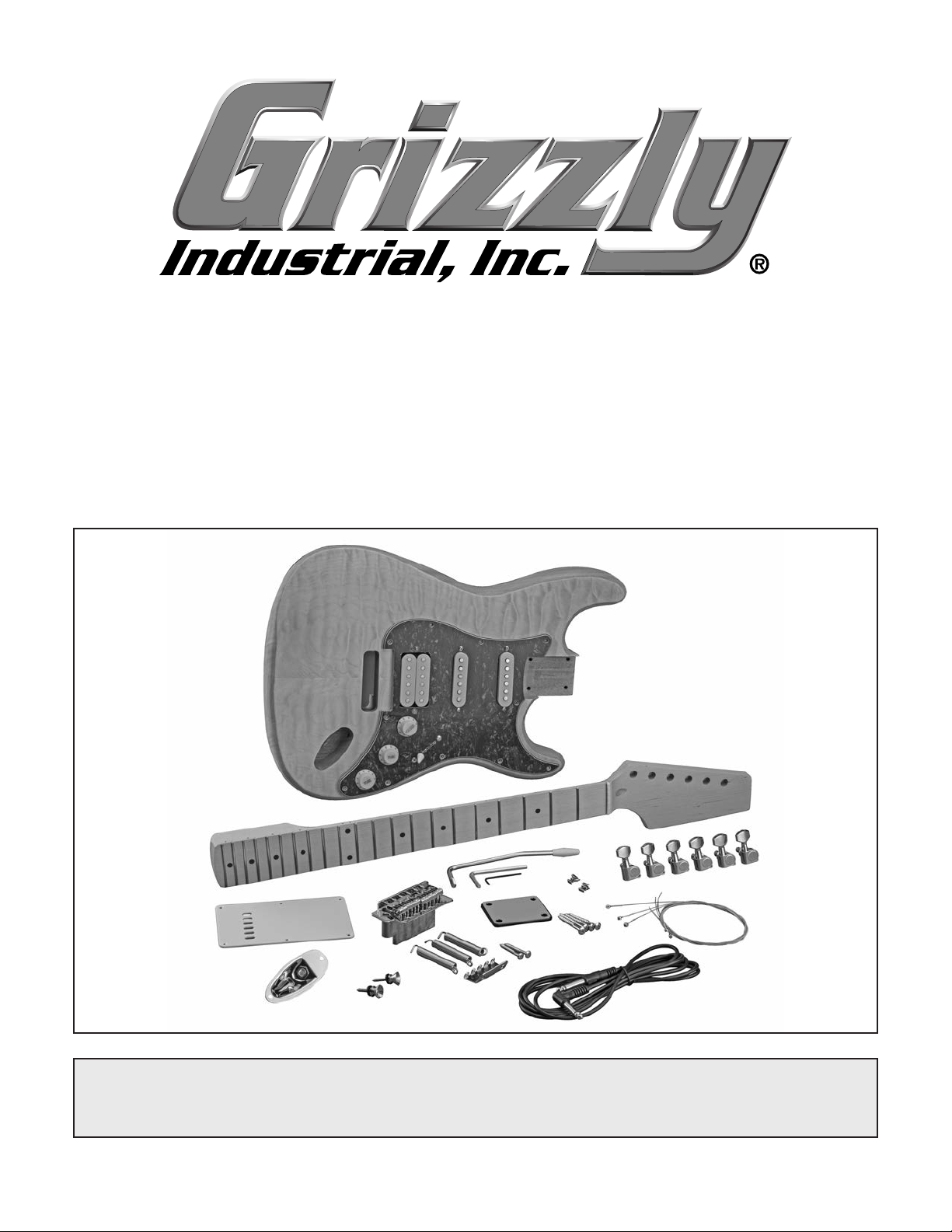

Needed for SetupUnpacking

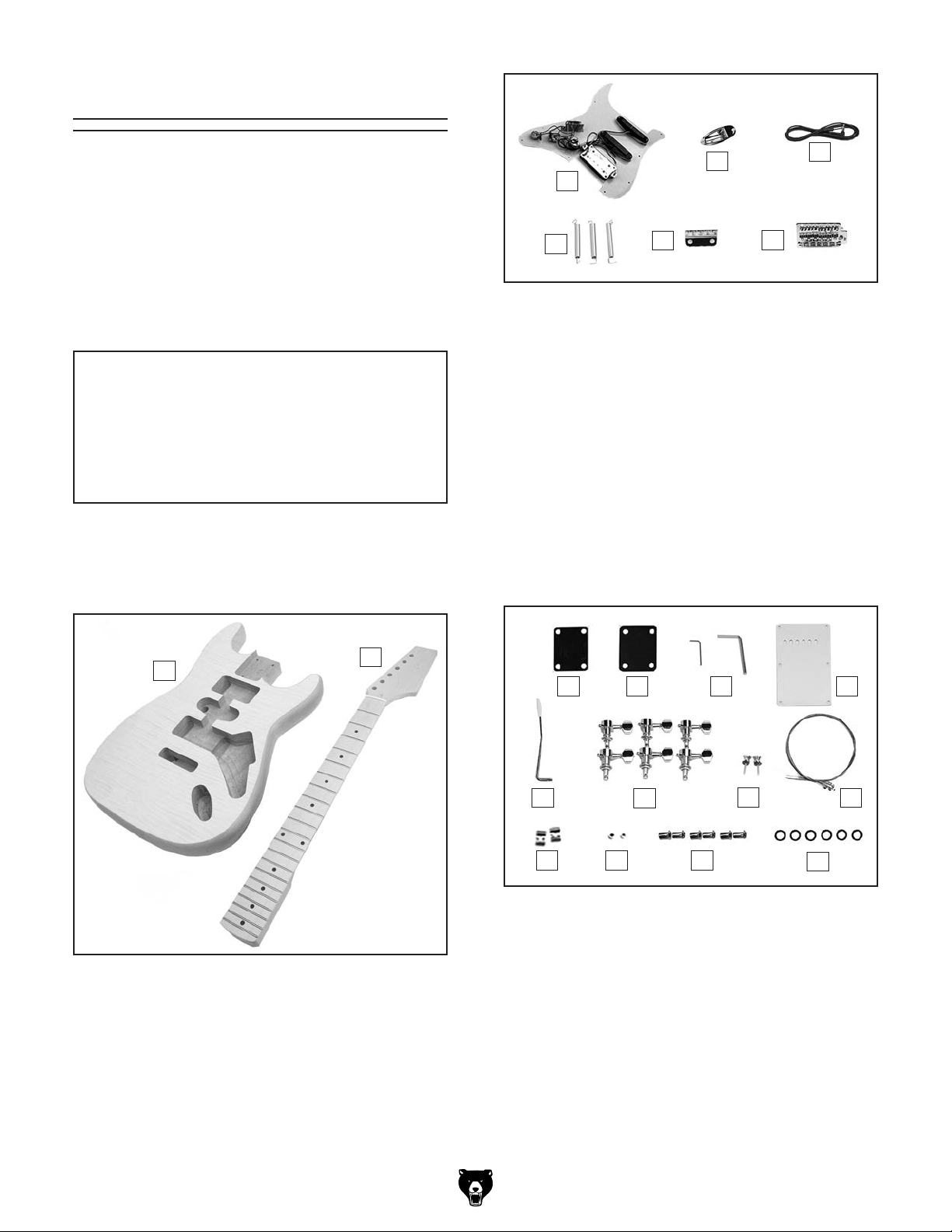

This instrument was carefully packaged for safe

transport. When unpacking, separate all enclosed

items from packaging materials and inspect them

for shipping damage. If items are damaged,

please call us immediately at (570) 546-9663.

IMPORTANT: Save all packaging materials until

your are completely satisfied with the instrument

and have resolved any issues between Grizzly or

the shipping agent. You must have the original

packaging to file a freight claim. It is also extreme-

ly helpful if you need to return your instrument.

Planning &

Preparation

Total time building this instrument will vary on

many factors. Variables such as glue manufactur-

er's instructions and curing time, temperature and

humidity at the time of building, and your schedule

are just a few of the factors that can affect the

length of time spent on this project.

Perhaps the biggest determinant of time spent

completing this instrument will be the type of fin-

ish and the finishing process used. Finishing this

instrument can be as simple as applying a single

coat of stain or lacquer that can be done rela-

tively quickly, up to a multi-coated finish that takes

weeks to harden.

Careful planning and budgeting ample time will

make this project easier and ensure you end up

pleased with your results. Good luck building your

instrument, and Grizzly hopes it turns out looking,

and sounding great.

Wear safety glasses during

the entire setup process!