Grizzly H0596 User manual

Other Grizzly Sander manuals

Grizzly

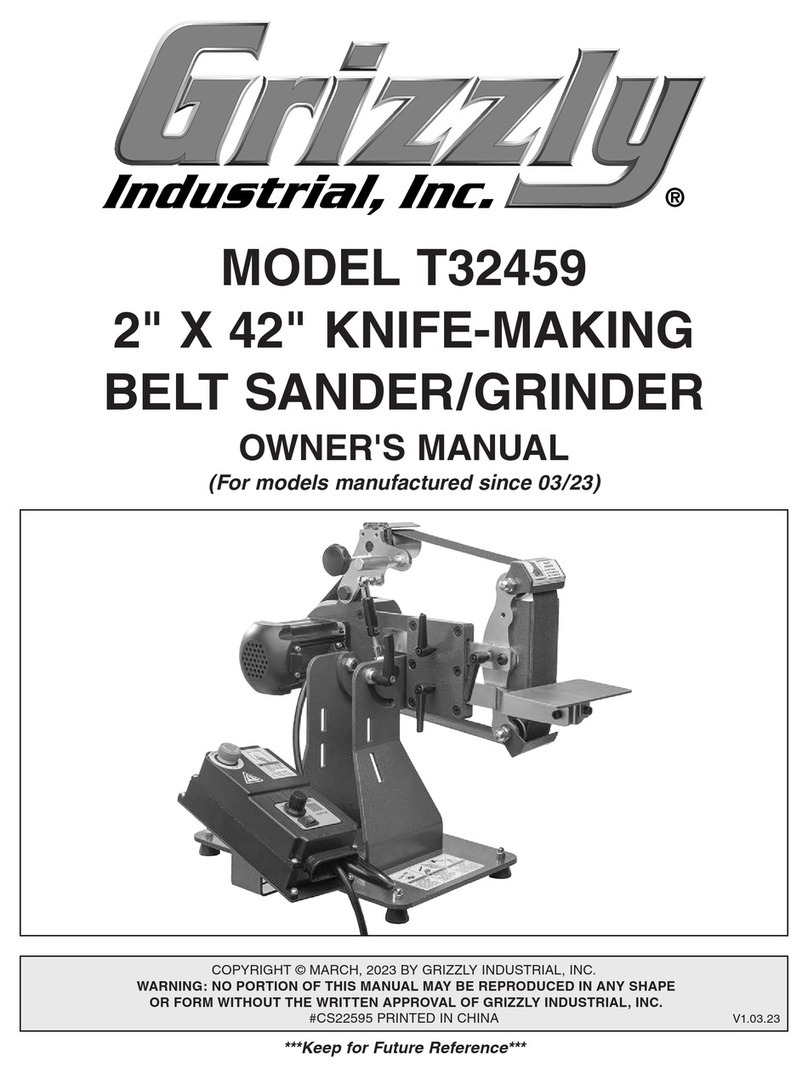

Grizzly T32459 User manual

Grizzly

Grizzly G0724 User manual

Grizzly

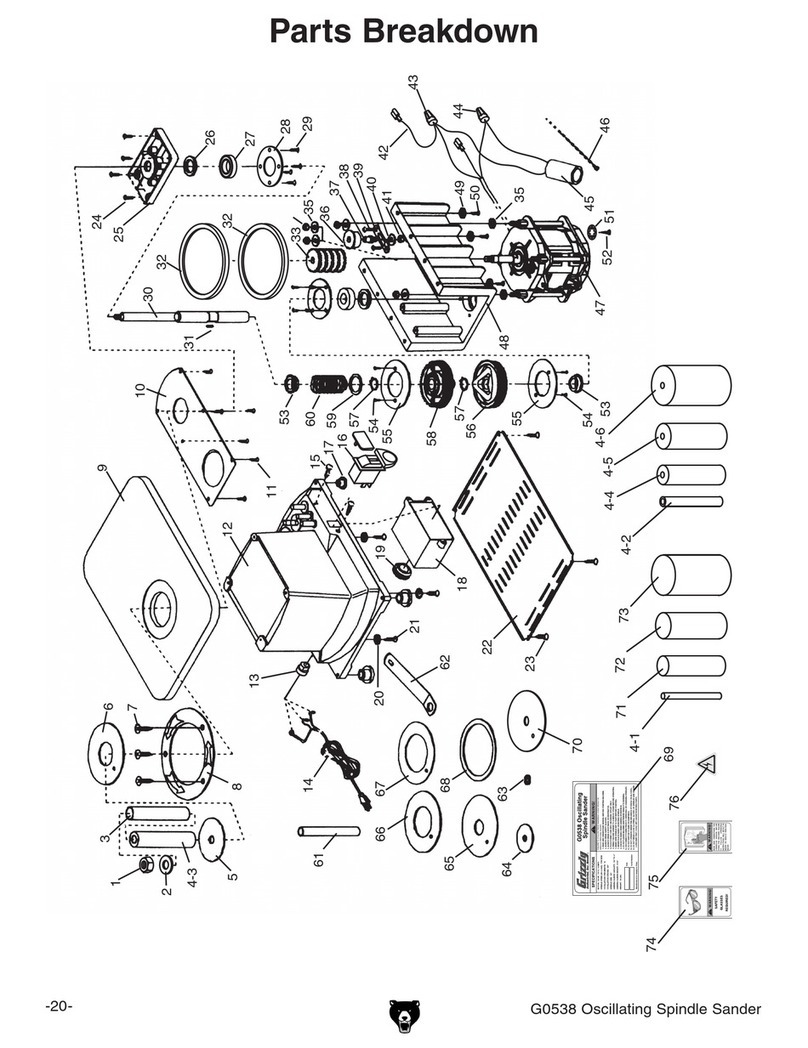

Grizzly G0538 Quick start guide

Grizzly

Grizzly G1066R User manual

Grizzly

Grizzly T32003 User manual

Grizzly

Grizzly G0565 User manual

Grizzly

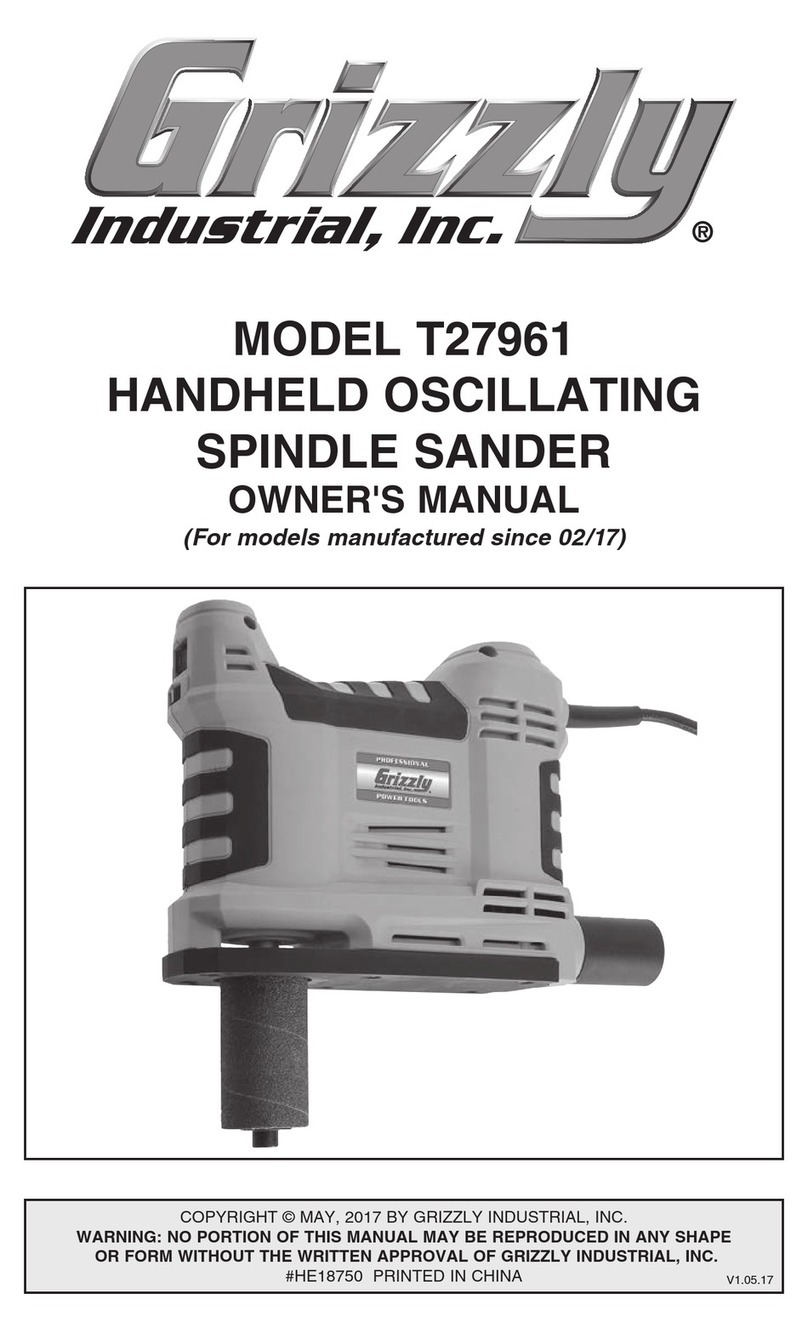

Grizzly T27961 User manual

Grizzly

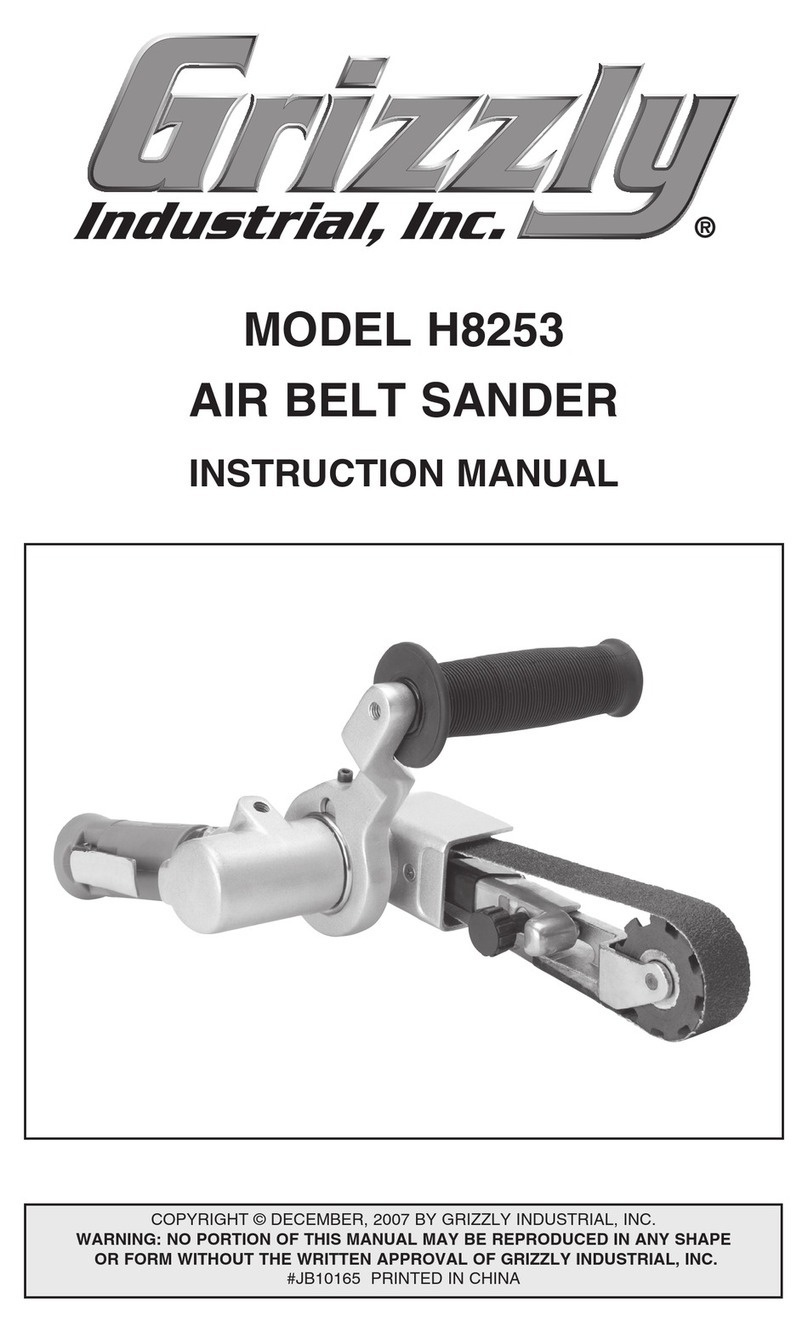

Grizzly H8253 User manual

Grizzly

Grizzly G0518 User manual

Grizzly

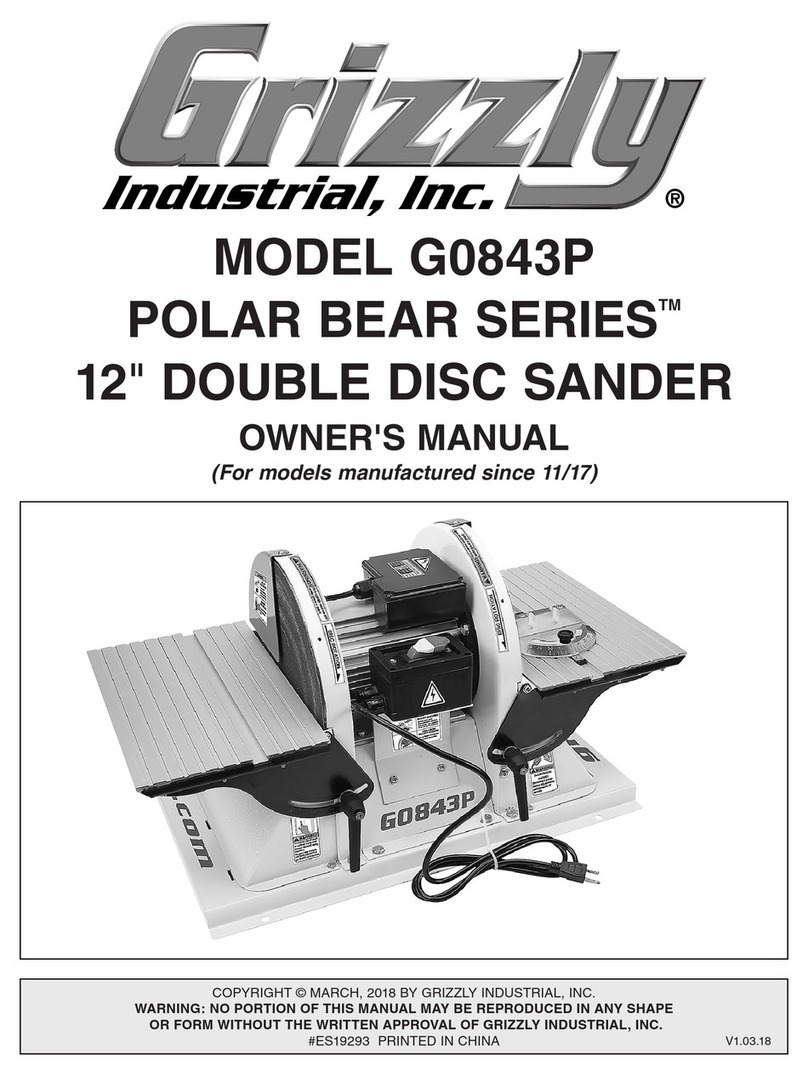

Grizzly POLAR BEAR Series User manual

Grizzly

Grizzly G1014Z User manual

Grizzly

Grizzly H8192 User manual

Grizzly

Grizzly H8120 User manual

Grizzly

Grizzly G1140 User manual

Grizzly

Grizzly H2881 User manual

Grizzly

Grizzly G0644 User manual

Grizzly

Grizzly G0529 User manual

Grizzly

Grizzly G5049Z User manual

Grizzly

Grizzly H6070 Instruction Manual

Grizzly

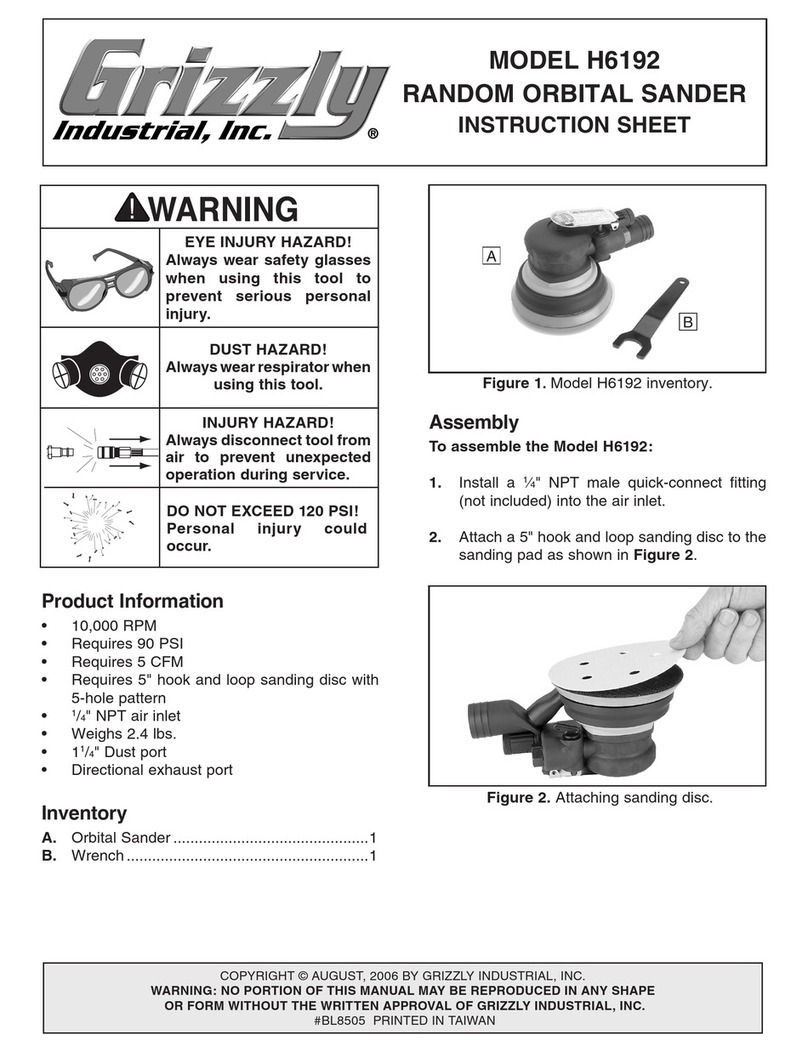

Grizzly H6192 User manual