2 | P a g e

Need Help? Email support@gropoint.com or visit www.gropoint.com/support

RIOT Technology Corp. | #220–10114 McDonald Park Rd | North Saanich V8L5X8, BC Canada | +1.250.412.6642

www.riotwireless.com | www.gropoint.com

All Rights Reserved ©2020, RIOT Technology Corp.

Table of Contents

Overview ........................................................................................................................... 4

Technology (TDT) .............................................................................................................. 4

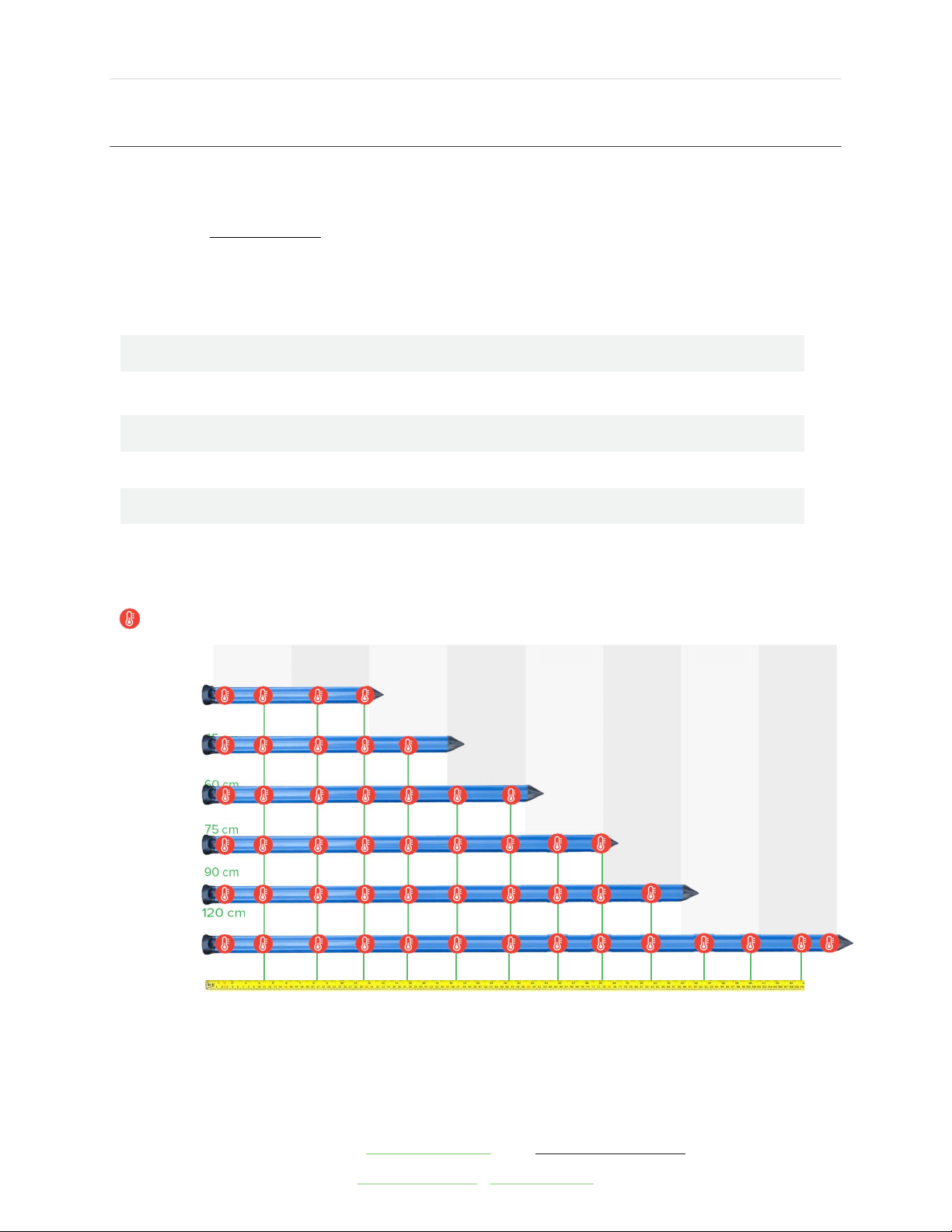

GroPoint™ Profile Model Variations ...................................................................................... 5

Probe Technology .............................................................................................................. 6

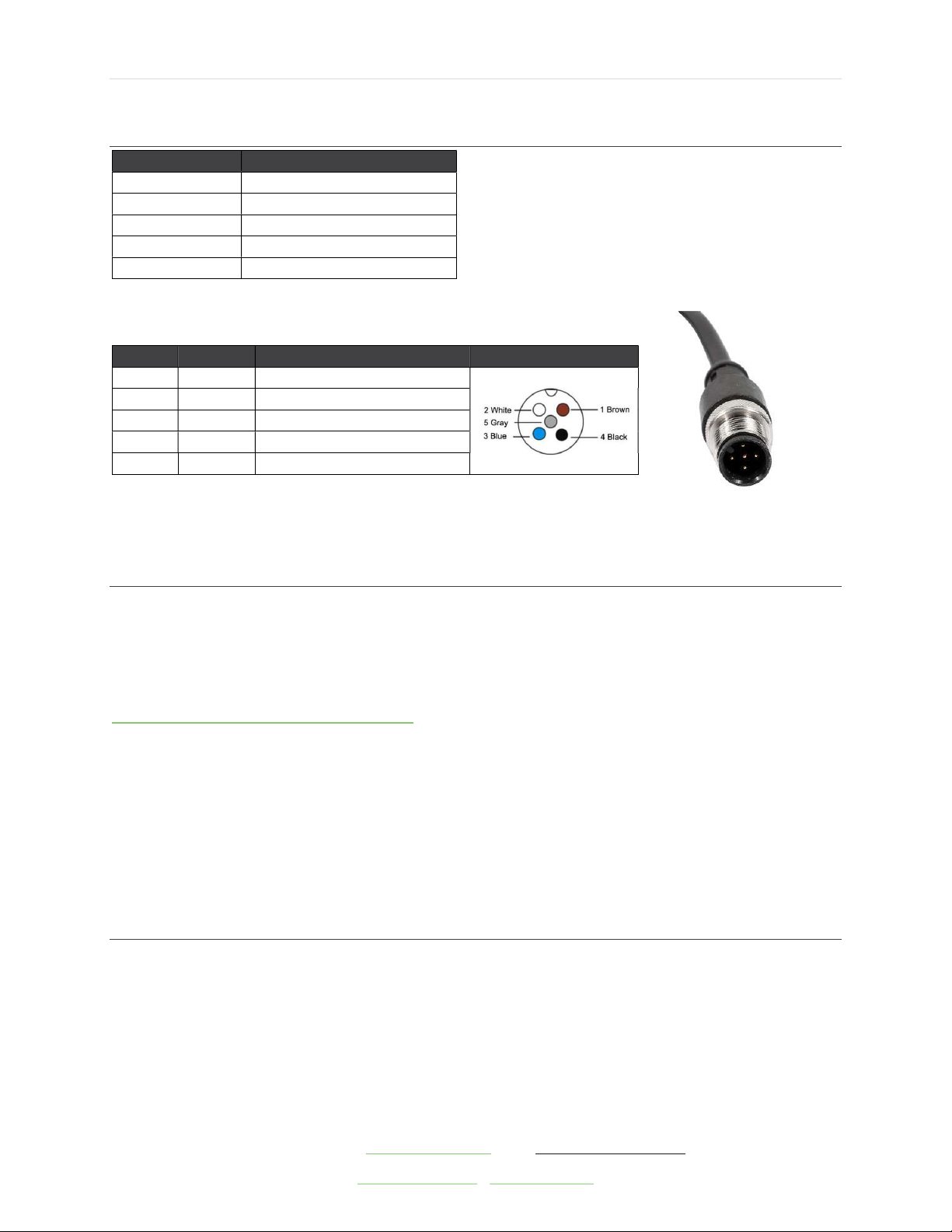

Wiring Connections ............................................................................................................ 7

Reading Methods ............................................................................................................... 7

Sensor Start Up Time / Measurement Time .......................................................................... 7

Important Things to Note ................................................................................................ 7

Basic SDI-12 Command List ................................................................................................ 8

How it Works ................................................................................................................. 8

Basic SDI-12 Command List ............................................................................................. 8

Understanding the Basic Commands .................................................................................... 8

Query Address Command: ?! ........................................................................................... 8

Acknowledge Active Command: a!.................................................................................... 9

Send Identification String Command: aI! .......................................................................... 9

Change Address Command: aAb! ..................................................................................... 9

Start Measurement Command: aM! or aM1! or aM2! .........................................................10

Start Concurrent Measurement Command: aC! .................................................................10

Send Data Command: aD0! or aD! ..................................................................................10

Extended SDI-12 Command List .........................................................................................11

Overview ......................................................................................................................11

Extended SDI-12 Command List ......................................................................................12

Extended Command Descriptions .......................................................................................13

Sensor Board Power Control: aXSc! .................................................................................13

Read/Write Operating Mode Setting: aXMn! .....................................................................13

Read/Write Coefficient/Scale Factor Setting: aXCn! ...........................................................13

Additional Product Information ...........................................................................................18

Specifications ................................................................................................................18

Ratings .........................................................................................................................18

Appendix A: Probe Installation / Extraction ..........................................................................19

Summary ......................................................................................................................19

Sensor Installation Guidelines .........................................................................................20