7. Vice installation on a workbench

Required tools:

-handheld drill / bench top upright drill

- wood drill bit ∅: 3, 4, 5, 6, 14, 30, 40 mm [0,12",0,16", 0,2", 0,24", 0,55", 1,18", 1,58"]

-manual / electrical screwdriver – depending on type and size of used screws

- wood saw

-screw vice

-hammer / mallet

-wood screws ∅6-8mm [0,24“-0,32“] - 13pcs - depending on type

-bolt M8

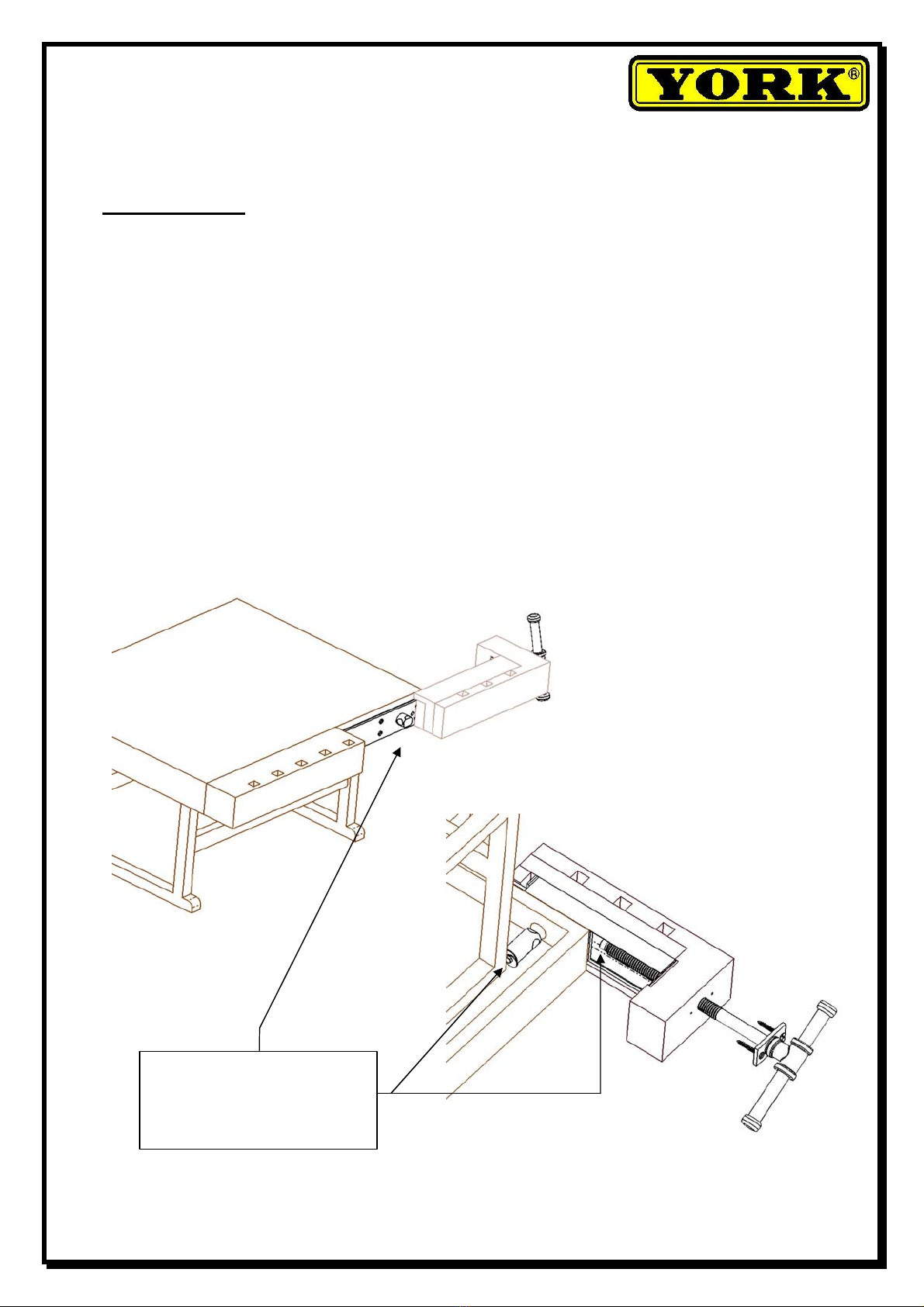

a) If the workbench has a collar, nut is secure sole piece and screw M8 from the inside the

workbench. If the workbench has no collar, spindle of the conduit cassette secure her position.

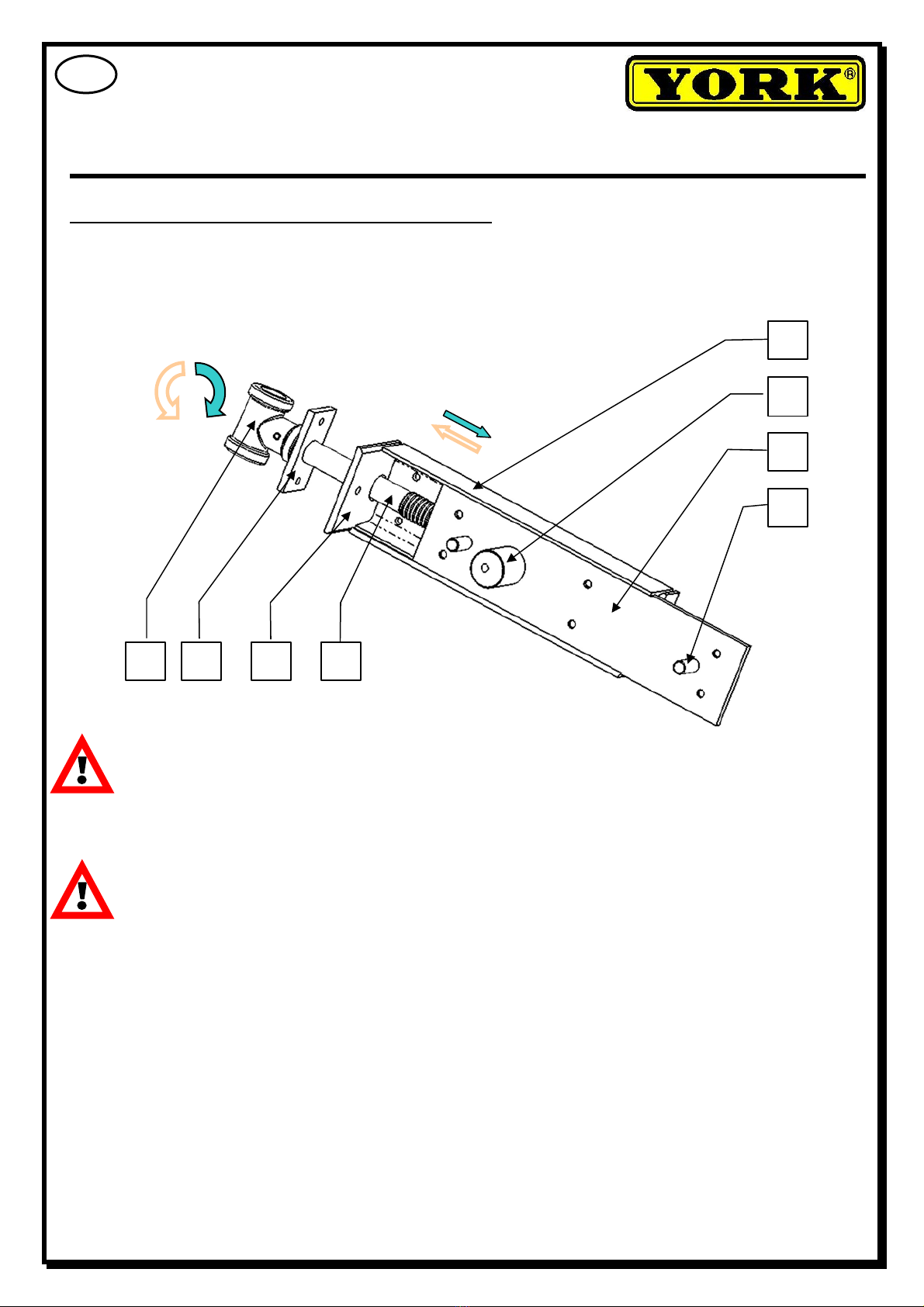

b) Prior to bolting spindle and nut, the face must unfastening and spindle draw out. See Fig .6b.

c) Vice installated insert clamping jaw to cover vice over hole for nut. Than follows put through

nut. See Fig.6a a 6b.

d) We bolt spindle and nut. We can fast the face screw-bolt again See Page 5, Fig.5.

Page 6 (of 7)

Fig.6a

Mounting nut on a

workbench

– put through after insert

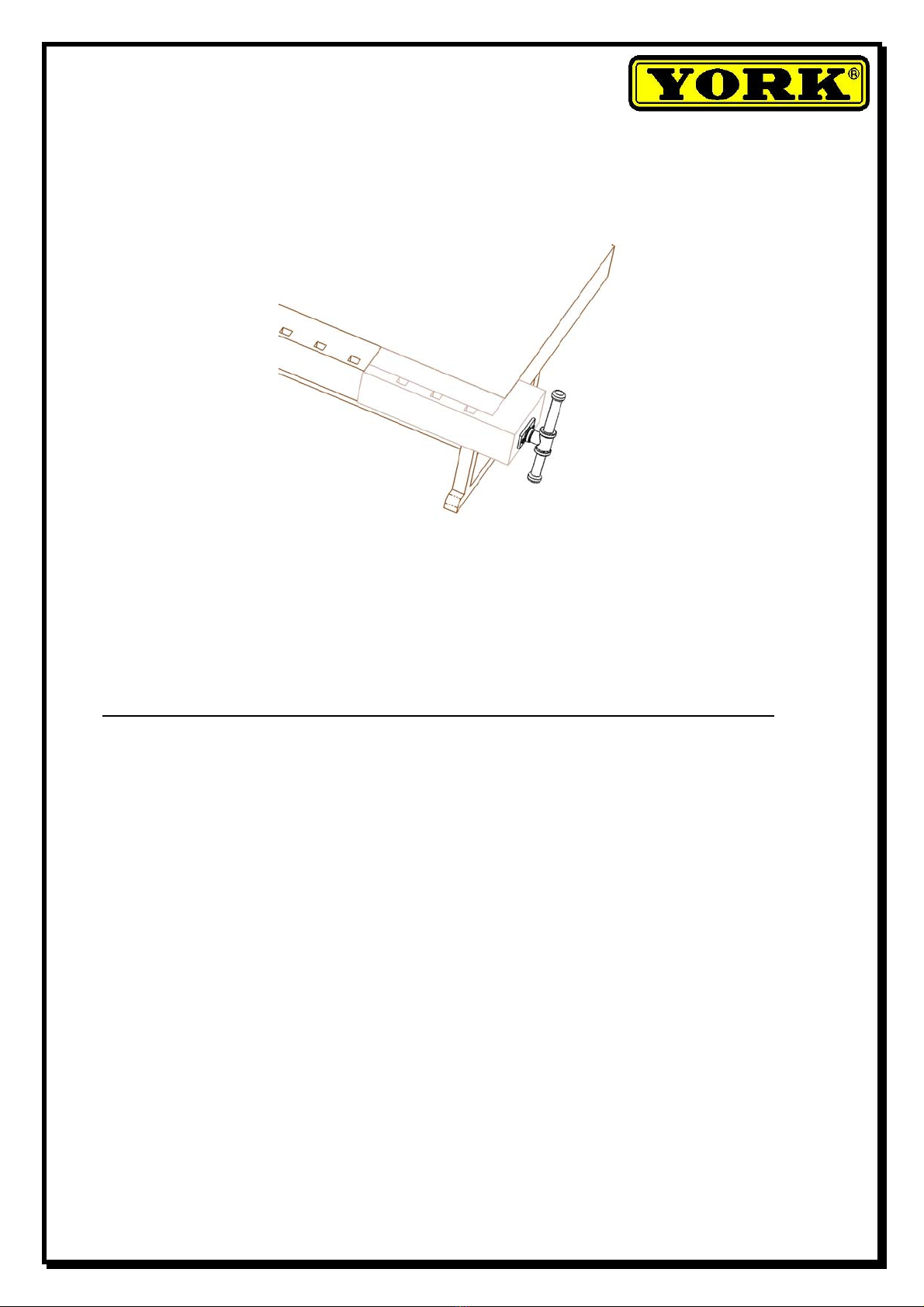

aw over hole for nut Fig.6b