8

Grouser Products warrants to the original purchaser of each item that the product be free from

defects in material and workmanship under normal use and service for a period of one year. If such

equipment is found to be defective within one year, it is the obligation of Grouser Products under this

warranty to repair or replace (exclusive of the cost of labor and transportation), any equipment or

parts, in the judgment of Grouser Products to be defective in material or workmanship.

All equipment or parts claimed to be defective in material or workmanship must be made

available for inspection at the place of business of a dealer authorized to handle the equipment

covered by this warranty, or, upon request by Grouser Products, shipped to the Grouser Products

factory in West Fargo, North Dakota. Grouser Products shall have no obligation to bear the cost of

labor or transportation in connection with replacement or repair of any such defective parts in the

setup process.

This warranty covers only defects in material and workmanship. It does not cover depreciation

or damage caused by normal wear, accident, improper assembly, improper adjustments, improper

maintenance including lack of proper lubrication, or improper use. Therefore, Grouser Products

liability under this warranty shall not be effective or actionable unless the equipment is assembled,

maintained and operated in accordance with the operating instructions accompanying the equipment.

Grouser Products shall have no liability if the equipment has been altered or reworked without the

written authorization of Grouser Products.

Grouser Products’ parts, which are furnished under this warranty and properly installed, shall

be warranted to the same extent as the original parts under this warranty if, and only if, such parts are

found to be defective within the original warranty period covering the original equipment.

Warranty

Contact Us

Improvements

Grouser Products Inc. is continually striving to improve its products. We reserve the right to change

prices, specication, or equipment at any time without notice. We also reserve the right to make

improvements or changes when it becomes practical and possible to do so without incurring any

obligation to make changes or additions to the equipment sold previously.

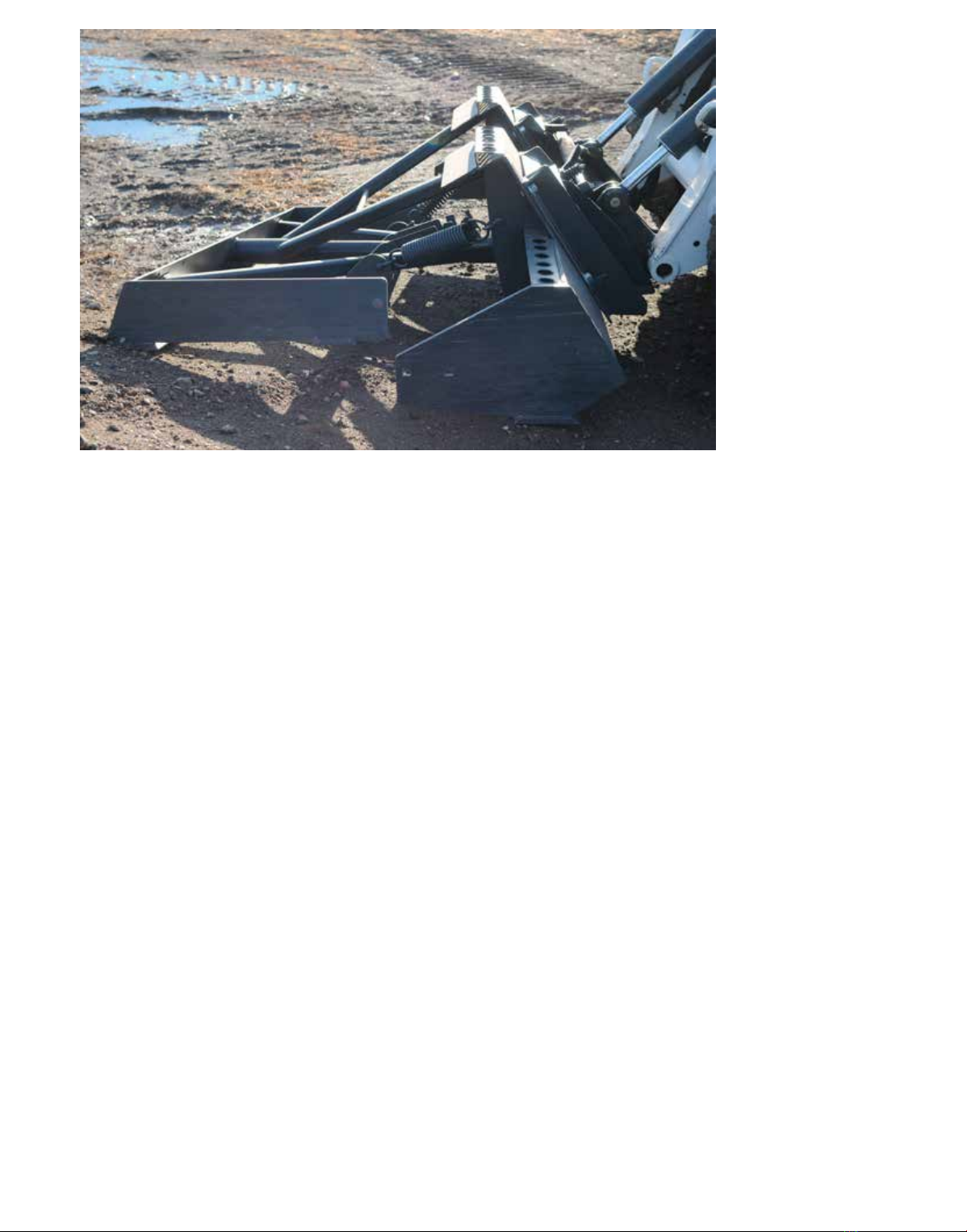

As always, if you have any questions about your V3Flex Plane or other products made by Grouser,

feel free to contact us.

Grouser Products

755 2nd Ave NW - West Fargo, ND 58078

Phone: 1-800-747-6182

Fax: 1-701-282-8131

E-mail: grouser@grouser.com

Website: www.grouser.com