• The BP-1530 Booster Pump is designed for use with all GrowoniX water lters 600 GPD and under.

• The pump is designed to boost low water pressure to optimal pressure.

• Do not exceed 79 psi output pressure.

ABOUT

CAUTIONS

MOUNTING

• The pump is equipped with an adjustable bypass valve which controls the maximum operating

pressure. In addition, never subject the pump to pressures above 80 PSI.

• Never operate the pump in a harsh environment or hazardous atmosphere,

since motor brush and switch may cause electrical arcing.

• Pumphead materials are designed for use with water only. Do not use with petroleum products.

• Always consider electrical shock hazard when working with and handling electrical equipment.

If uncertain, consult an Electrician. Electrical wiring should only be done by a qualied Electrician

per Local and State Electrical Codes.

• The pump should be mounted in a dry place and away from any source of heat. If an enclosure is

used, special provisions for cooling the motor may be necessary. Consult the Factory.

• Do not subject the pump to extreme high or low (freezing) temperatures while in operation.

(Operating ambient temperature range is 32ºF to 115ºF).

• The pump may be mounted in any position. If “ceiling mounted”, however, with the pumphead

upside down, air entrapment may reduce the operational performance by up to 15%.

READ ENTIRE MANUAL THOROUGHLY

BEFORE INSTALLING THIS HIGH PRESSURE-BOOSTING PUMP.

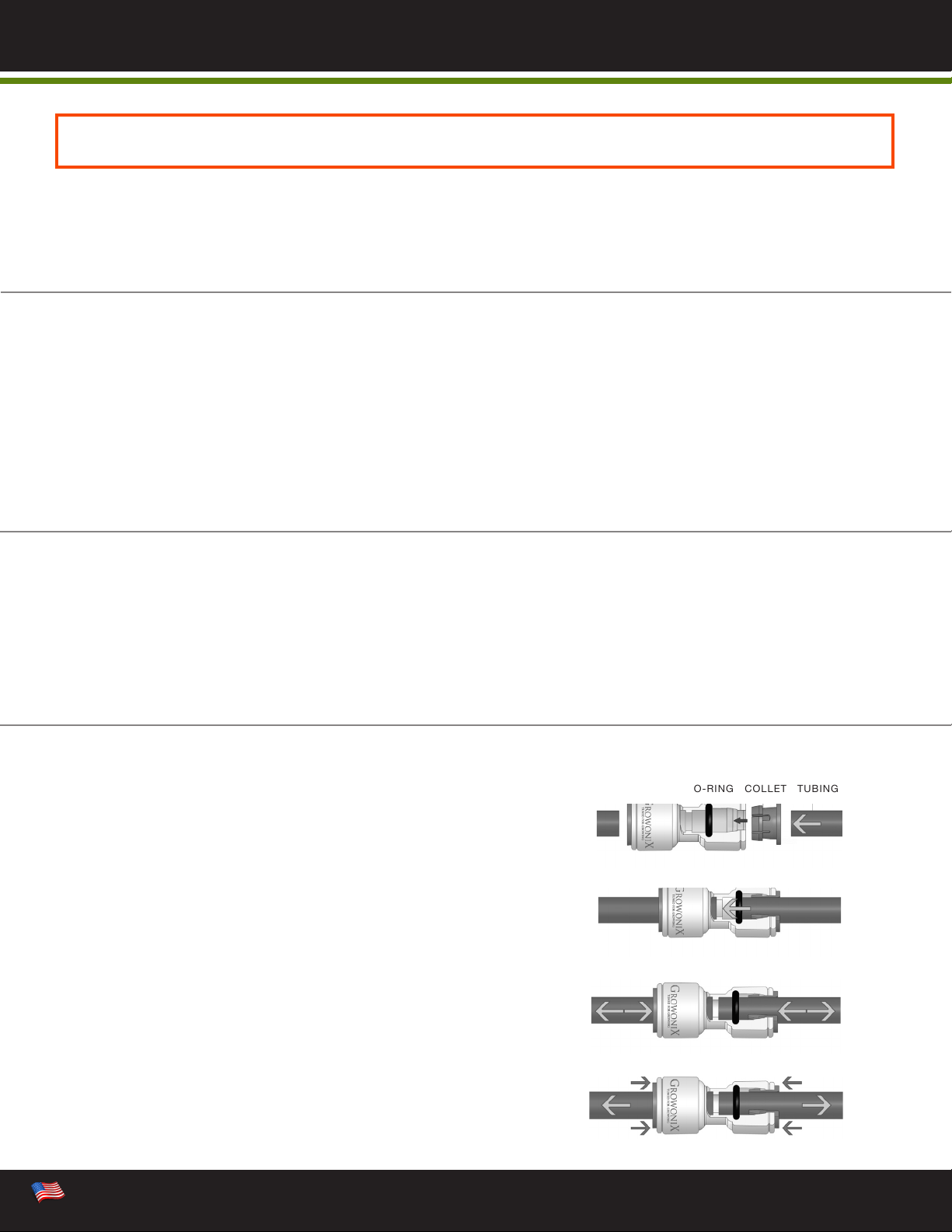

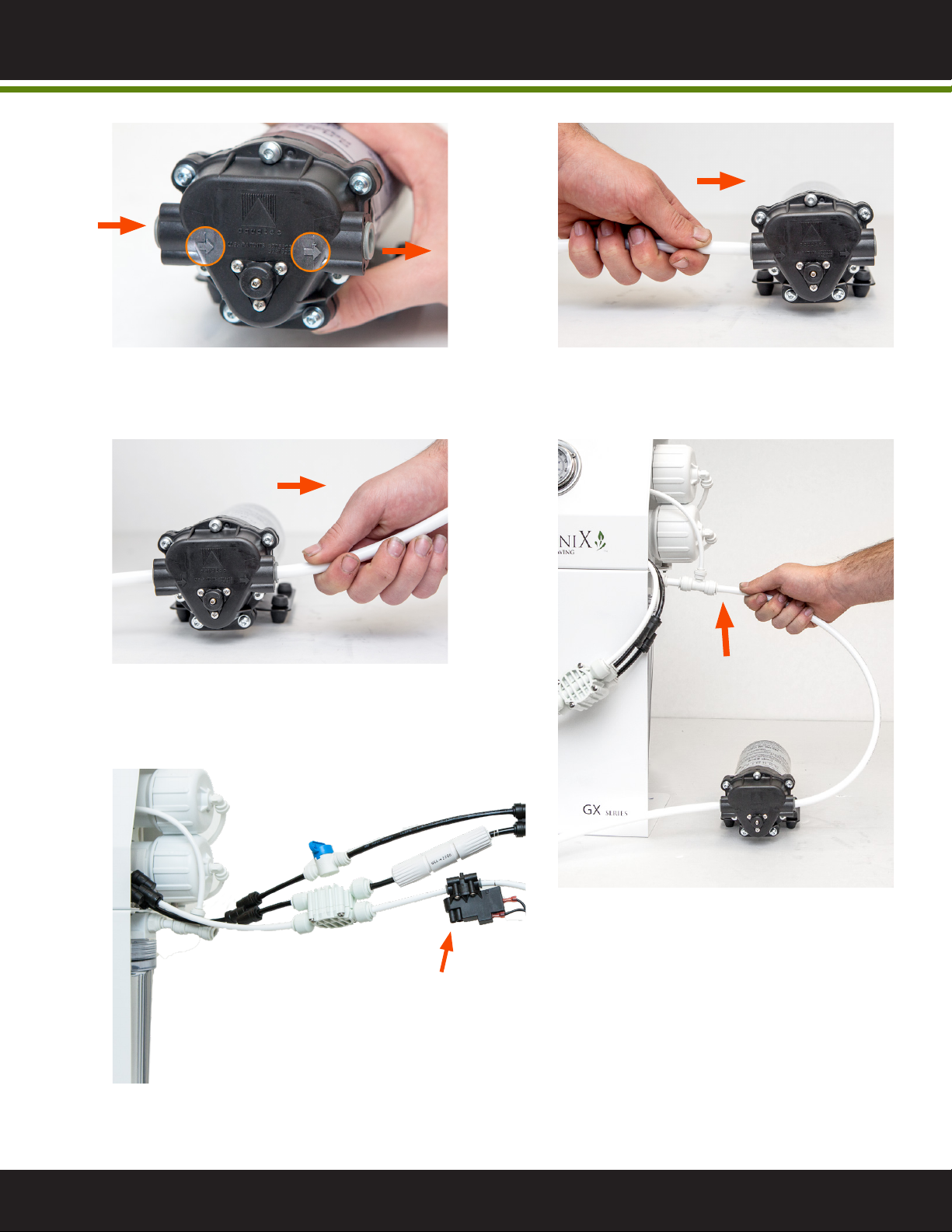

INSERT TUBE INTO FITTING

Push the tubing through the collet and dual o-rings until it bottoms

out against the tube stop.

The collet holds the tube in place and the dual o-rings provide a leak

resistant seal.

MAKE A CLEAN TUBE CUT

Cut the tube squarely and if using plastic tubing, ensure that the cut has

not made the tube out of round.

Also ensure that the tube has a smooth outside diameter without any

burrs or score marks prior to inserting it into the tting.

TEST AND INSPECT

Push and pull the tubing toward and away from the tting to ensure

that it has been installed properly.

Test and inspect the installation for any leaks.

TUBE REMOVAL

Relieve pressure from the tubing and tting. Push uniformly around

the collet ange against the tting body while pulling the tubing away

from the tting to release it.

PUSH COLLET IN PULL TUBE OUT

GROWONIX WATER FILTERS USE QUICK CONNECT FITTINGS

THAT ALLOW FOR EASY MAINTENANCE.

3

Built in the U.S.A.Built in the U.S.A. 3

BASIC INFORMATION