4

Oxiperm 164C 4-10 kg en

Contents

Installation data ................................................................................................ 3

Installation diagram ......................................................................................... 3

1 General .................................................................................................... 7

1.1 Introduction................................................................................................ 7

1.2 Using this Document ................................................................................. 7

1.3 Guarantee ................................................................................................. 7

2 Safety Information .................................................................................. 8

2.1 Use of the System ..................................................................................... 8

2.2 Obligations of Owner................................................................................. 8

2.3 Avoidance of Danger ................................................................................ 8

3 Technical Data ........................................................................................ 9

3.1 General Data ............................................................................................. 9

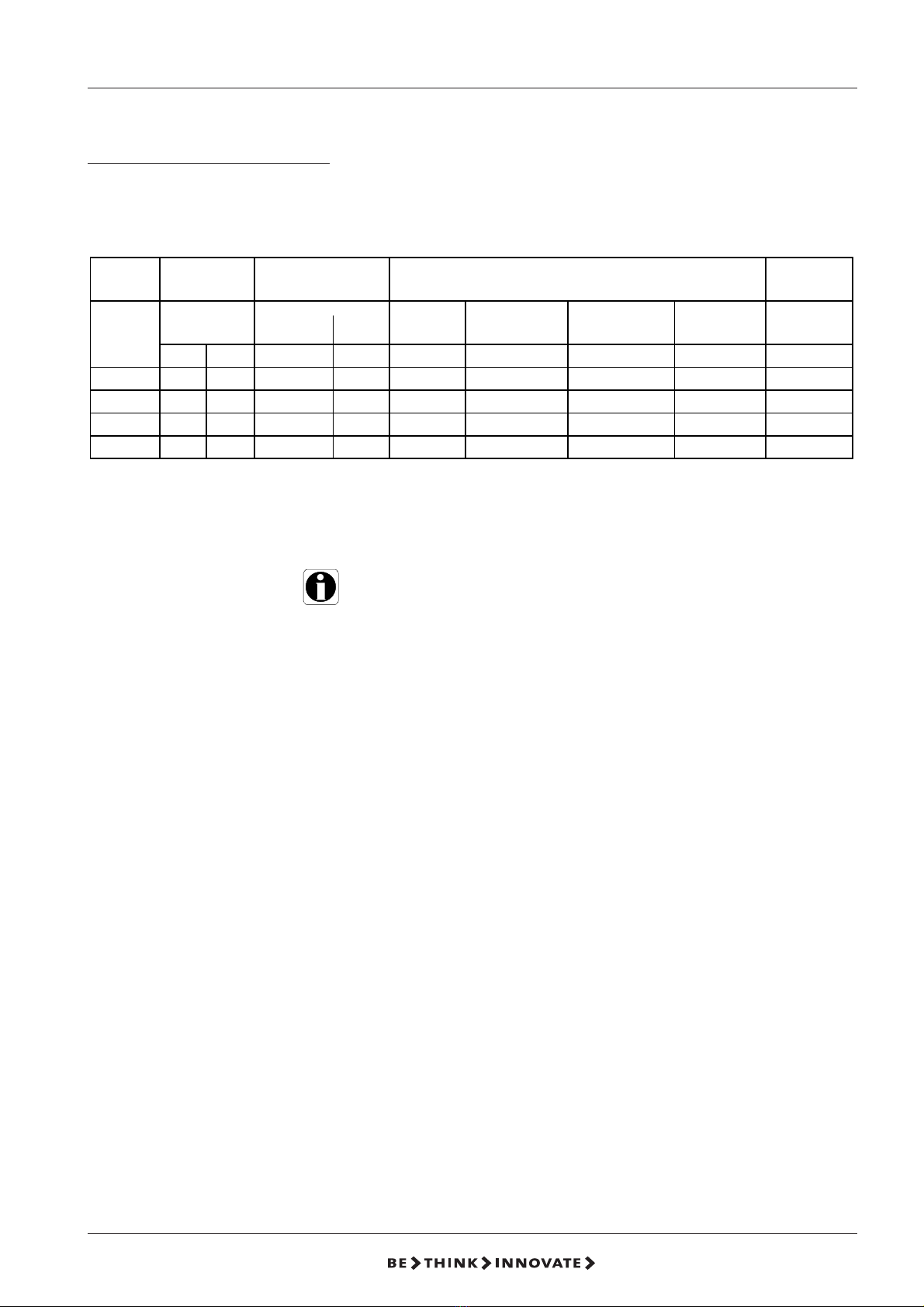

3.1.1 Performance and Consumption Data ............................................ 9

3.1.2 Connection Data and Weights .................................................... 10

3.1.3 Dimensions .................................................................................. 10

3.2 Electrical Data ......................................................................................... 13

3.3 Delivery State .......................................................................................... 13

4 Fundamentals ........................................................................................14

4.1 Chlorine Dioxide for Water Treatment ..................................................... 14

4.1.1 Generation of Chlorine Dioxide ................................................... 14

4.2 Functional Sequence .............................................................................. 15

5 Design and Function .............................................................................16

5.1 System Design ........................................................................................ 16

5.2 Components ............................................................................................ 18

5.2.1 Suction Lines for the Chemicals .................................................. 18

5.2.2 Dosing Pump HCl/NaClO2 .......................................................... 18

5.2.3 Flowmeters .................................................................................. 19

5.2.4 Bypass Line ................................................................................. 19

5.2.5 Preliminary Dilution for Hydrochloric Acid .................................. 19

5.2.6 Reactor ........................................................................................ 19

5.2.7 Solution Tank for ClO2 ................................................................. 20

5.2.8 Overflow Unit for Solution Tank .................................................... 20

5.2.9 Suction for Solution Tank ............................................................. 20

5.2.10 Water Tank for Preliminary Dilution .............................................. 20

5.2.11 Purging Unit ................................................................................. 20

5.2.12 Options ......................................................................................... 21

5.3 Mode of Operation of System .................................................................. 22

6 Installation .............................................................................................24

6.1 Transport and Storage ............................................................................ 24

6.2 Unpacking ............................................................................................... 24

6.3 Installation Location ................................................................................ 24

6.4 Installation Diagrams .............................................................................. 25

6.4.1 Installation Diagram for Water Supply and

Connection of the Chemicals ...................................................... 25

6.4.2 Installation Diagram for Sampling of ClO2,

Suction and Overflow ................................................................... 26

6.5 Floor Mounting of

System Frame .......................................................................................... 27