SL 531 en

V2.0 III

Content

Imprint............................................................................................. 2

1 General ........................................................................................... 4

1.1 General Information .........................................................................4

1.2 Using this document ........................................................................4

1.3 Guarantee ........................................................................................4

2 Safety ............................................................................................. 5

2.1 Using the Component ......................................................................5

2.2 Obligations of the owner ..................................................................5

2.3 Avoidance of danger ........................................................................5

3 General description ........................................................................ 6

3.1 Function ...........................................................................................6

3.2 Structure ..........................................................................................6

4 Installation ...................................................................................... 6

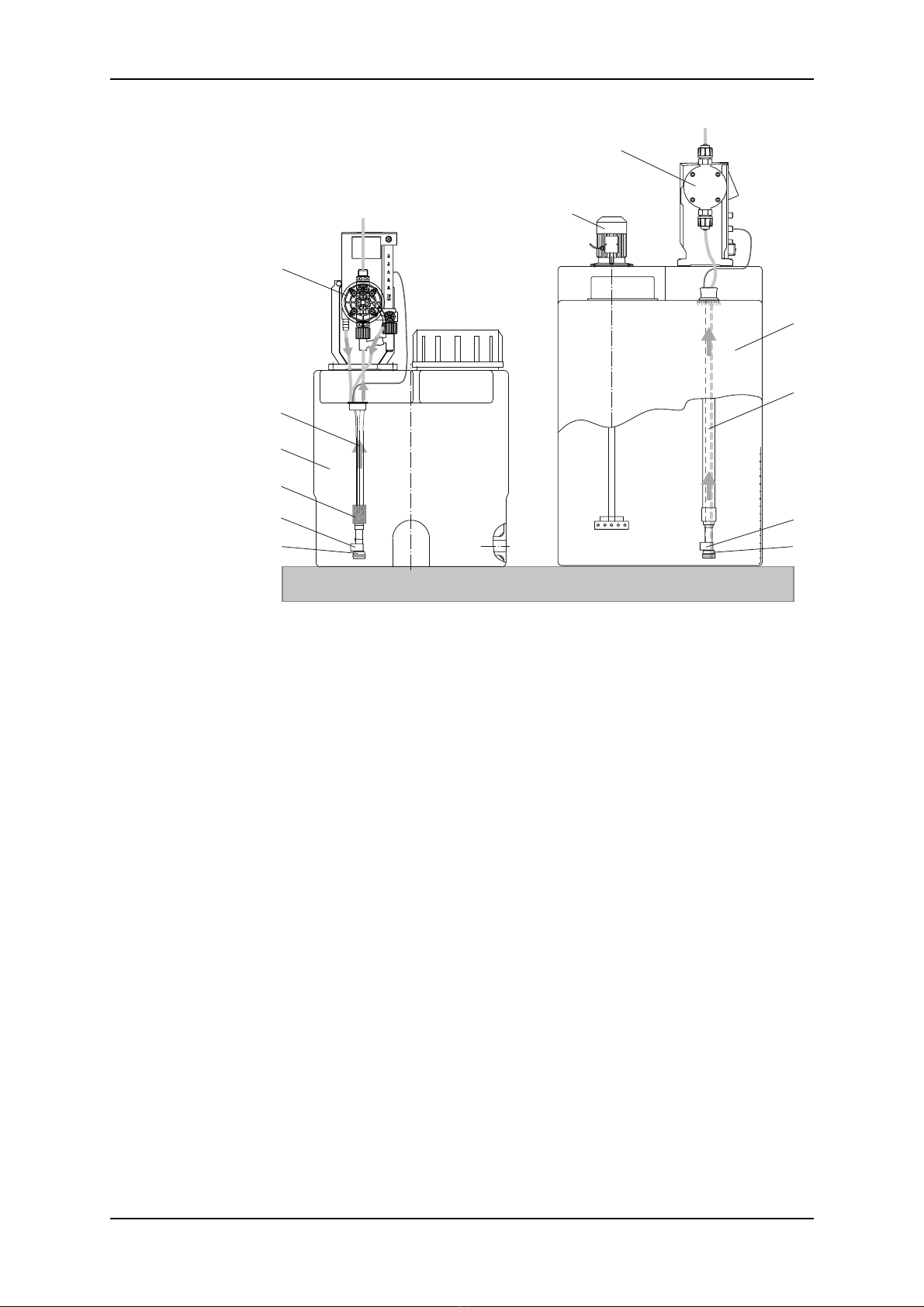

4.1 Installation (examples) .....................................................................7

4.2 Installing the Suction Line ................................................................8

4.2.1 Fixing the suction line to the reservoir/tank ...................................9

4.2.2 Connecting the suction line to the pump .....................................10

5 Empty Signal and Pre-Empty/ Empty Signal ................................ 11

5.1 Empty signal ..................................................................................11

5.2 Empty/Pre-empty signal ................................................................11

5.3 Reed Switch - Technical Data .......................................................12

5.4 Connecting the Empty or Pre-Empty/Empty signal .......................12

5.4.1 Round plug (DDI 222) ..................................................................12

5.4.2 Flat plug (DDI 209, AR electronics) .............................................12

5.4.3 Cable assignment of plugs ..........................................................12

6 Maintenance ................................................................................. 13

6.1 Cleaning ........................................................................................13