English (GB) Installation and operating instructions

Original installation and operating instructions

Table of contents

1. General information ............. 4

1.1 Hazard statements .............. 4

1.2 Notes ..................... 4

2. Applications ................. 5

2.1 Abbreviations ................. 5

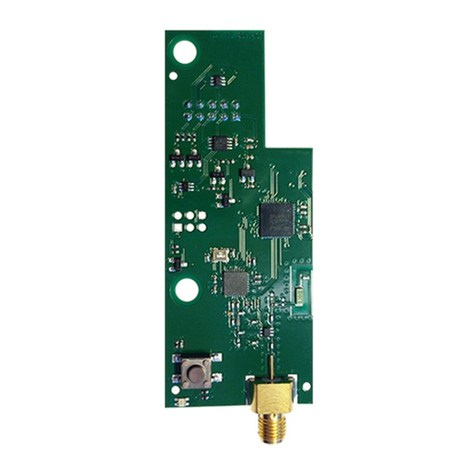

2.2 CIM 500 Ethernet module .......... 6

3. Installation .................. 7

3.1 Security .................... 7

3.2 Connecting the Ethernet cable ........ 8

3.3 Selection of Industrial Ethernet protocol . .. 9

3.4 Setting the IP addresses ........... 9

3.5 Connection to the webserver .........10

4. Status LEDs .................11

5. Data activity and link LEDs .........12

6. Fault finding .................13

6.1 PROFINET IO.................13

6.2 Modbus TCP or BACnet IP ..........15

6.3 EtherNet/IP ..................17

6.4 GRM IP ....................19

7. Technical data ................21

7.1 PROFINET technical specifications .....22

7.2 Modbus TCP technical specifications ....23

7.3 BACnet IP technical specifications ......23

7.4 EtherNet/IP technical specifications .....25

8. Disposing of the product ..........26

1. General information

Read this document before you install the

product. Installation and operation must

comply with local regulations and accepted

codes of good practice.

1.1 Hazard statements

The symbols and hazard statements below may

appear in Grundfos installation and operating

instructions, safety instructions and service

instructions.

DANGER

Indicates a hazardous situation which, if

not avoided, will result in death or serious

personal injury.

WARNING

Indicates a hazardous situation which, if

not avoided, could result in death or

serious personal injury.

CAUTION

Indicates a hazardous situation which, if

not avoided, could result in minor or

moderate personal injury.

The hazard statements are structured in the following

way:

SIGNAL WORD

Description of the hazard

Consequence of ignoring the warning

• Action to avoid the hazard.

1.2 Notes

The symbols and notes below may appear in

Grundfos installation and operating instructions,

safety instructions and service instructions.

Observe these instructions for explosion-

proof products.

A blue or grey circle with a white graphical

symbol indicates that an action must be

taken.

A red or grey circle with a diagonal bar,

possibly with a black graphical symbol,

indicates that an action must not be taken

or must be stopped.

If these instructions are not observed, it

may result in malfunction or damage to the

equipment.

Tips and advice that make the work easier.

4

English (GB)